A kind of preparation method of hollow titanium dioxide microsphere

A technology of titanium dioxide and silicon dioxide, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as difficult-to-control reactions, achieve simple preparation process, stable structure, and improve electron transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

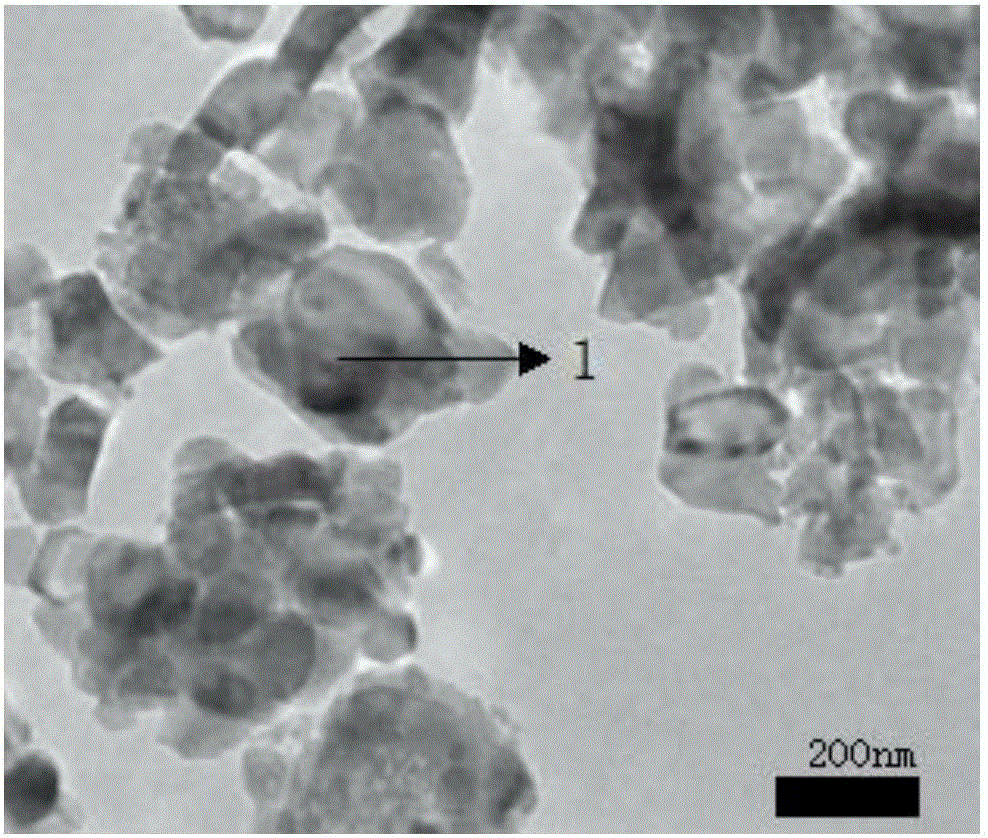

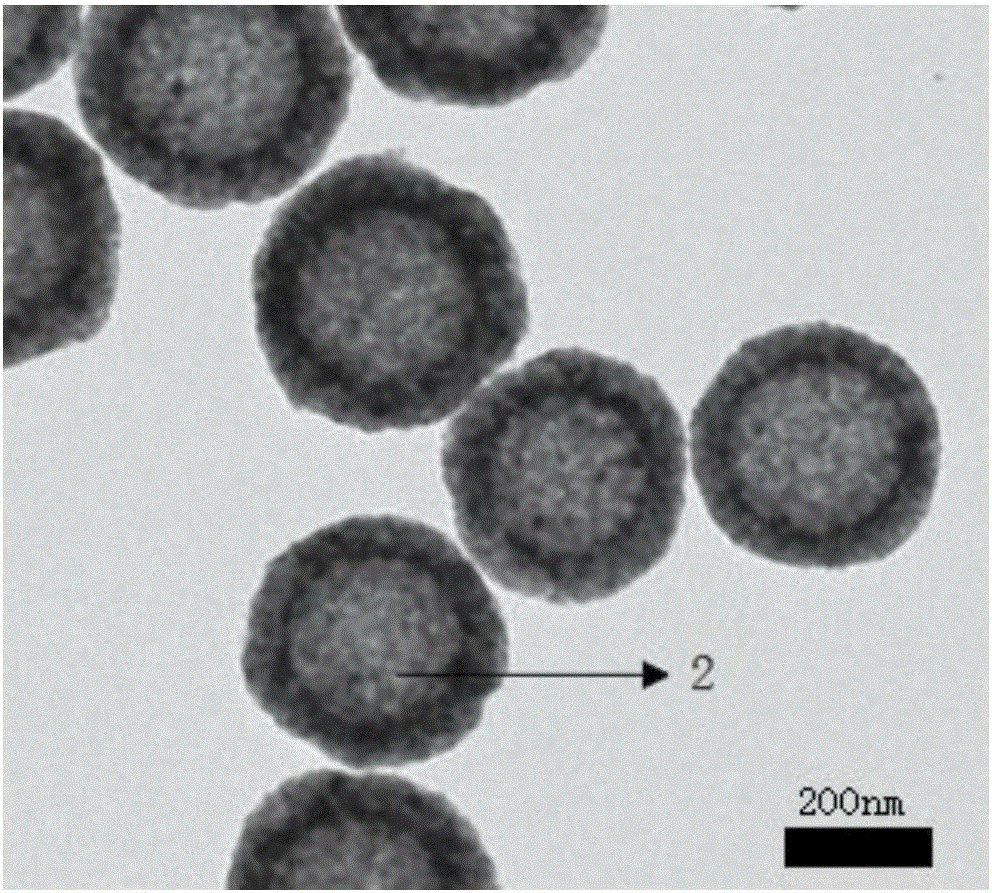

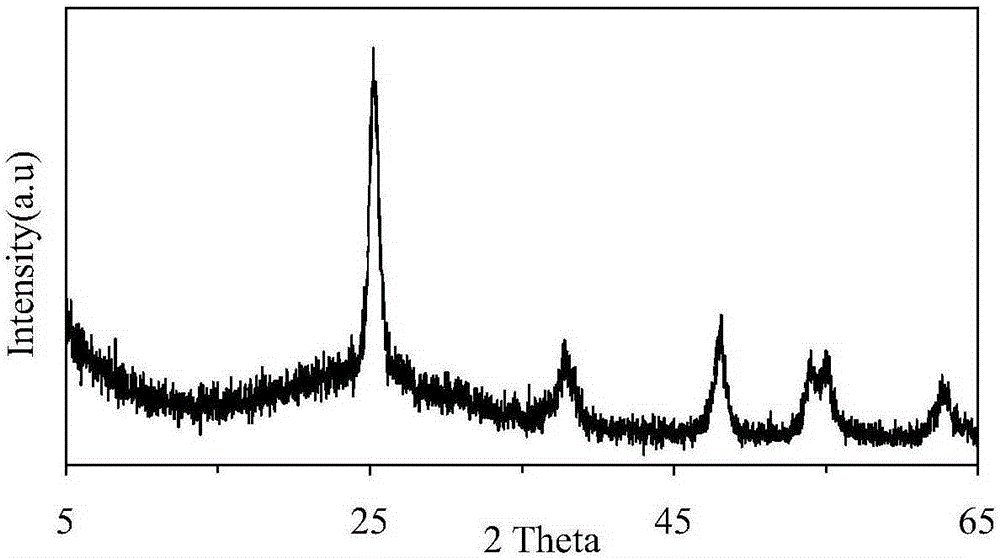

Image

Examples

Embodiment 1

[0029] A preparation method of hollow titanium dioxide microspheres, comprising the following steps:

[0030] (1) Take tetraethyl silicate, deionized water, ethanol and ammonia water and mix and stir for 4 hours. The volume ratio of tetraethyl silicate: deionized water: ethanol: ammonia water (mass fraction is 28%) is 1:5:25 : 0.5.

[0031] (2) Centrifuge the mixed solution in step (1) to separate the silica microspheres, wash with ethanol, and disperse into the ethanol solution. The mass and volume ratio of the silica microspheres to ethanol is 1g / 10mL.

[0032] (3) Disperse the silica-ethanol mixture into the mixture of hydroxypropyl cellulose, ethanol and deionized water and stir for 30 minutes. The mass of the hydroxypropyl cellulose is the total mass of the silica-ethanol mixture. 3-5%; the mass of the deionized water is 10% of the total mass of the silica-ethanol mixed solution; the mass of the ethanol is 15-20 times the total mass of the silica-ethanol mixed solution. ...

Embodiment 2

[0039] Photocatalytic degradation of rhodamine B with the titanium dioxide hollow microspheres made: get 5 mg of titanium dioxide microspheres, put them into 25 ml of rhodamine B solution, the concentration of rhodamine B is 20 mg / L. The volume of the reactor is 50mL, and the mixed solution is stirred for 30 minutes to ensure that it reaches the adsorption equilibrium. Turn on the 300W mercury lamp, take 1ml solution every 5min to measure the concentration of rhodamine B, and analyze its degradation degree. The results showed that its degradation rate reached 98% within 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com