Blue light polarizing film, preparation method thereof, blue light backlight source and liquid crystal display device

A polarizing film and backlight technology, which is applied in polarizing elements, chemical instruments and methods, optics, etc., can solve the problems of difficult uniformity regulation of luminescent films, increased difficulty in synthesizing luminescent materials, and many luminescent substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

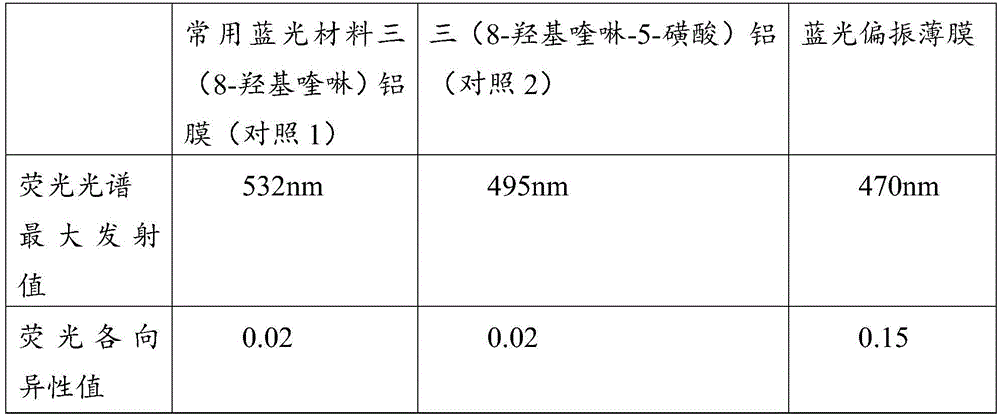

Embodiment 1

[0021] Embodiment 1. Preparation of blue light polarizing film

[0022] 1.1 Preparation of magnesium aluminum hydrotalcite

[0023] Magnesium aluminum hydrotalcite, its structural formula is Mg 2 Al(OH) 6 NO 3 LDH ([Mg 2 Al(OH) 6 NO 3 ].xH 2 O), weigh Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 ·6H 2 O, and then they were dissolved in 100 mL of deionized aqueous solution in which Mg(NO 3 ) 2 ·6H 2 The concentration of O was controlled at 0.02mol / L, transferred to a three-necked flask, stirred under nitrogen protection, titrated with 0.5mol / L NaOH solution to pH=8.0, and the mixed solution was transferred to a reaction kettle and reacted in an oven at 80°C for 48h After the reaction, the product was centrifuged, washed and dried to obtain the target product Mg 2 Al(OH) 6 NO 3 LDH.

[0024] 1.2. Preparation of magnesium aluminum hydrotalcite solution

[0025] Take 1gMg 2 Al(OH) 6 NO 3 LDH was added into 100 mL of formamide and stirred for 16 h to obtain a formamid...

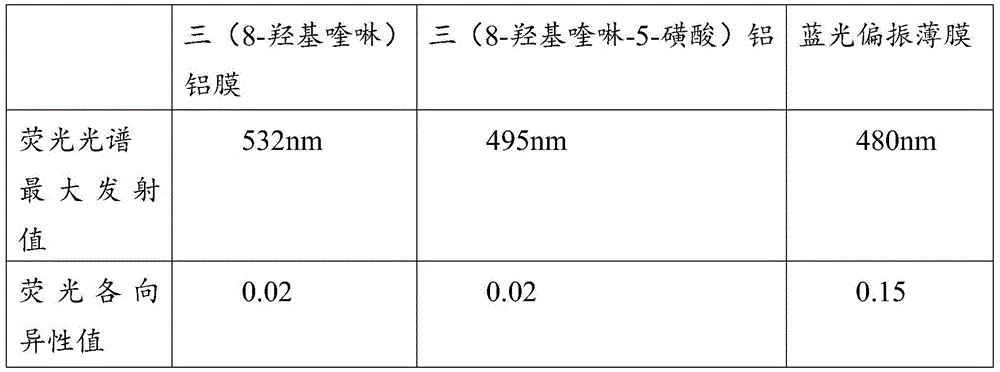

Embodiment 2

[0039] Embodiment 2. Preparation of blue light polarizing film

[0040] 2.1 Preparation of magnesium aluminum hydrotalcite

[0041] Magnesium aluminum hydrotalcite, its structural formula is Mg 2 Al(OH) 6 NO 3 LDH ([Mg 2 Al(OH) 6 NO 3 ].xH 2 O). Weigh Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 ·6H 2 O, and then they were dissolved in 100 mL of deionized aqueous solution in which Mg(NO 3 ) 2 ·6H 2 The concentration of O was controlled at 0.12mol / L, transferred to a three-necked flask, stirred under nitrogen protection, titrated with 0.5mol / L NaOH solution to pH = 10.5, and the mixed solution was transferred to a reaction kettle and reacted in an oven at 160°C for 10h After the reaction, the product was centrifuged, washed and dried to obtain the target product Mg 2 Al(OH) 6 NO 3 LDH.

[0042] 2.2. Preparation of magnesium aluminum hydrotalcite solution

[0043] Take 2gMg 2 Al(OH) 6 NO 3 LDH was added into 100 mL of formamide and stirred for 16 h to obtain a for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com