Screw rotor cooling device of screw vacuum pump

A screw vacuum pump and rotor cooling technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluid, can solve the increase of noise and vibration of the screw vacuum pump, affect the dynamic balance performance of the screw rotor, and it is difficult to accurately control the cooling. Cavity size and other issues, to achieve the effect of improving yield, improving cooling effect, and easy monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

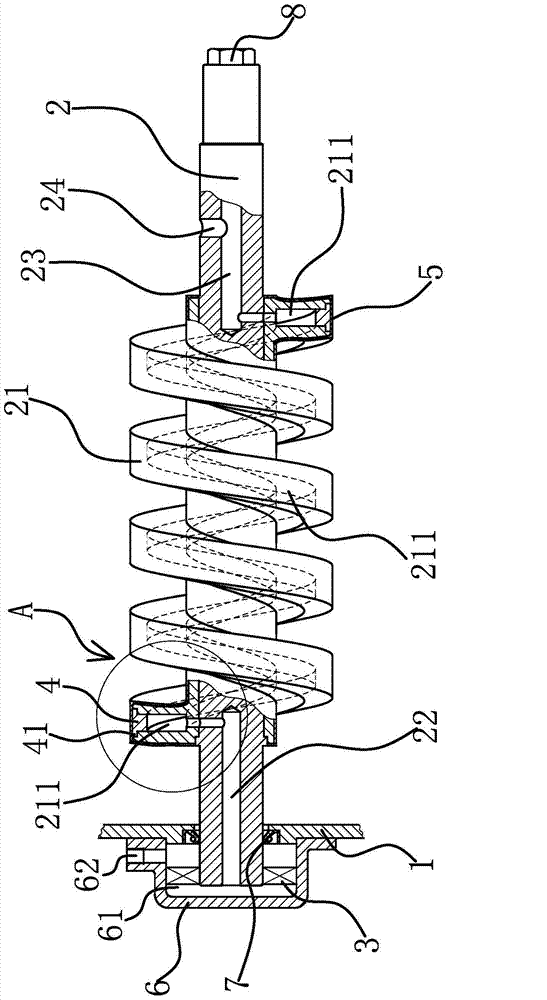

[0021] The screw vacuum pump includes a pump body 1 and a screw rotor 2, the screw rotor 2 is installed in the pump body 1, and the screw rotor 2 is made of metal material. The screw rotor cooling device of the screw vacuum pump includes a hydraulic pump 3 , a coolant tank and a coolant channel 211 .

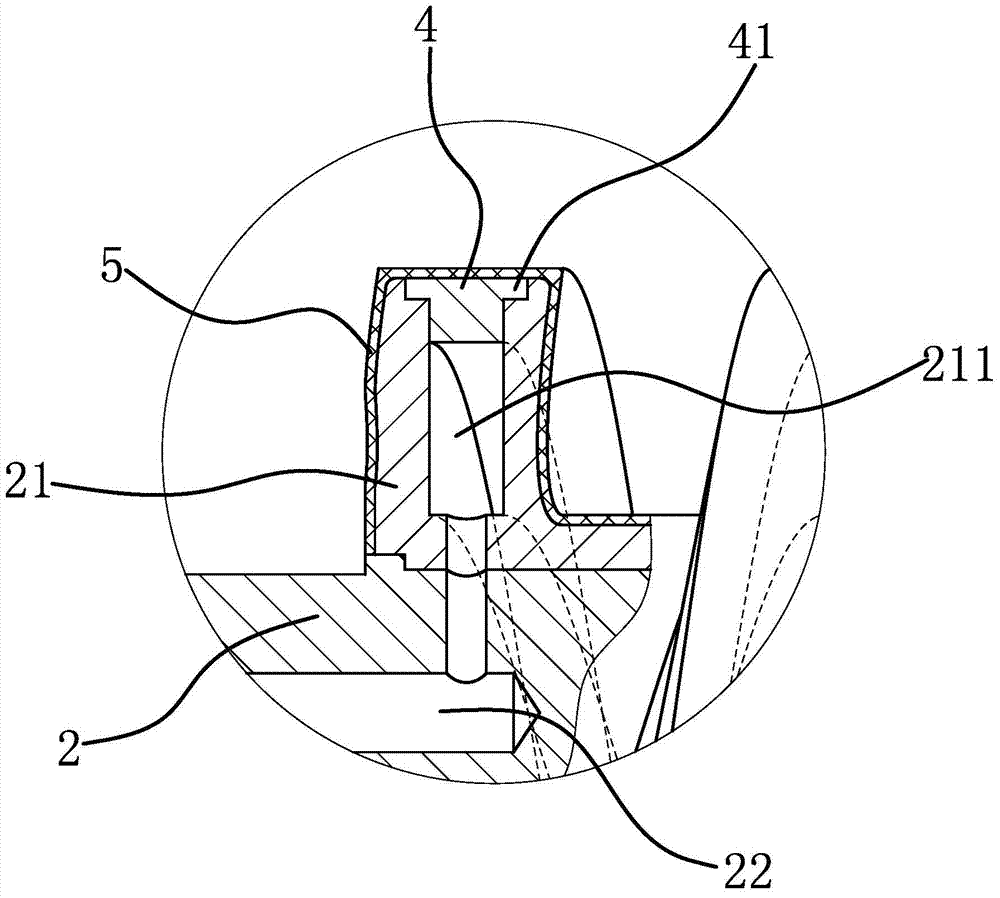

[0022] Specifically, as figure 1 As shown, the screw rotor 2 has helical teeth 21 , and the cooling liquid channel 211 is opened on the helical teeth 21 of the screw rotor 2 along the helical direction of the helical teeth 21 . The upper surface of the cooling liquid passage 211 has an opening open to the outside world, and an insert 4 matching the shape of the opening is fixed at the opening of the cooling passage. In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com