Device and method for measuring organic matters entrained in water phase in solvent extraction process

A technology for organic matter in water phase, applied in the fields of chemical industry and metallurgy, can solve the problems of inability to directly measure the concentration of organic matter, high cost, complicated operation process, etc., to achieve the effect of easy observation and measurement, and easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

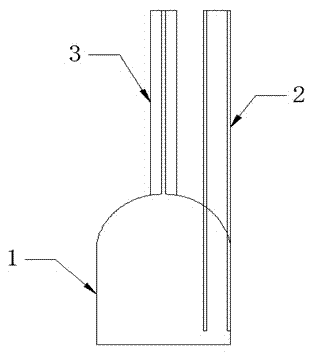

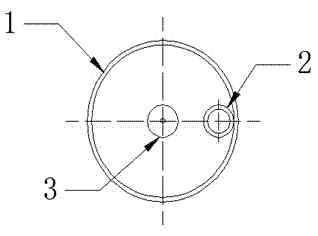

[0027] The present invention is a device for metering organic matter entrained in the water phase of the solvent extraction process, which is composed of a closed container 1, the inside of the container 1 is a hollow structure, and a feeding column 2 is arranged in the container 1. Both ends of the charging column 2 are open, the upper end of the charging column 2 protrudes from the container 1, the charging column 2 is perpendicular to the bottom of the container 1, and the top of the container 1 A capillary 3 is arranged in the center, the two ends of the capillary 3 are open, the capillary 3 communicates with the inside of the container 1 , and the side wall of the capillary 3 is provided with a scale.

[0028] Further, the top of the container 1 is arc-shaped.

[0029] Further, the lower end of the feeding column 2 is close to the bottom of the container 1 .

[0030] Further, the lower end of the feeding column 2 is close to and perpendicular to the bottom of the contain...

Embodiment 2

[0034] 1) After the extraction or stripping operation, the water phase is separated, and the water phase is injected into the instrument from the feeding column to the calibrated scale. After each operation, keep the same liquid level scale. No air bubbles can be generated during the feeding process, and the liquid levels of the two tubes should be kept at the same level.

[0035] 2) Put the special separation device equipped with the water phase into the centrifuge, and control the speed of the centrifuge to centrifuge for a certain period of time. Under the action of centrifugal force, oil and water are separated to form an organic liquid column in the capillary.

[0036] 3) Read the height of the organic phase directly according to the scale indication on the capillary or measure the height with a vernier caliper. Before use, inject water to the scale to obtain the total volume, and finally convert the column height into volume to obtain the volume content of the organic ...

Embodiment 3

[0041] Present embodiment at first weighs the weight of the device of the present invention, then injects into centrifuge bottle 1 with distilled water (as figure 1 Shown), mark and weigh after reaching a certain liquid level in the capillary. According to the formula V=(M1-M2) / ρ, the weight difference before and after adding water calculates the used separation device volume of the present invention, and its volume is 30.21ml. Then simulate the copper solvent extraction process, use the organic phase containing different concentrations of extractant Lix984N and the copper ore leaching solution (PH 2.0) to mix and extract according to the volume ratio of 1:1, the stirring time is 8 minutes, the stirring speed is 400r / min, and the extraction operation is separated. A raffinate was obtained. The raffinate is fed from column 2 (such as figure 1 shown) into the calibrated scale. Then centrifuge for 10 min, and the speed is controlled at 3000 r / min. Under the action of centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com