Slab laser beam expanding alignment system capable of adjusting in electric closed loop mode

A laser beam expansion and closed-loop technology, applied in the field of laser collimation beam expansion optical systems, can solve the problems of manual adjustment of the safety of operators, inability to take into account the collimation of the slat divergence angle, and inability to adjust in real time. Good effect, good collimation effect, high adjustment precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

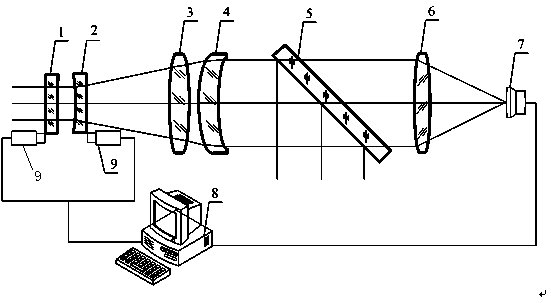

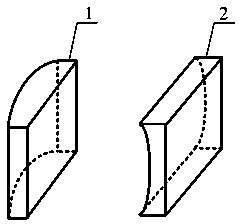

[0021] Such as figure 1 , the present invention includes a slab laser, a first cylindrical lens, a second cylindrical lens, a first ball lens, a second ball lens, a computer, a stepper motor and a far-field detection system; the first cylindrical lens and the second cylindrical lens are mutually Orthogonal placement; the first cylindrical lens and the second cylindrical lens are respectively connected to the stepping motor; the computer is respectively connected to the stepping motor and the far-field detection system; the laser beam emitted by the slab laser passes through the first cylindrical lens, the second The cylindrical lens, the first ball lens and the second ball lens are injected into the far-field detection system; the computer receives the feedback signal of the far-field detection system and controls the operation of the stepping motor according to the feedback signal to control the movement of the first cylindrical lens and the second cylindrical lens. Location...

Embodiment 2

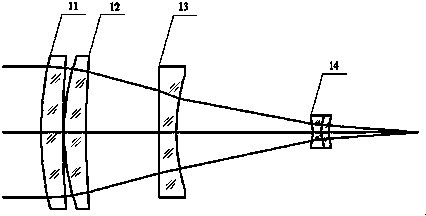

[0031] The basic structure of this embodiment is the same as that of Embodiment 1, and the difference is that the focusing lens 6 is changed into a long focal length achromatic focusing lens group, such as image 3 As shown, it consists of a meniscus spherical lens, a plano-concave lens and a doublet lens group containing two spherical lenses.

[0032] The meniscus spherical lens 11 has a clear aperture of Φ50mm and a focal length of 290mm. The material is H-ZF7LA. The surface is coated with an anti-glare anti-reflection film, and the transmittance is greater than 99.8%.

[0033] The meniscus spherical lens 12 has a clear aperture of Φ50mm and a focal length of 186mm. The material is H-ZF7LA. The surface is coated with an anti-glare anti-reflection film, and the transmittance is greater than 99.8%.

[0034] Plano-concave lens, the clear aperture is Φ50mm, the focal length is -116mm, the material is H-ZF7LA, the surface is coated with anti-glare antireflection film, and the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com