Pole coil and preparation method thereof

A magnetic pole coil and coil technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of complex design and structure of rotor coil leads, and achieve the effects of avoiding throwing out, improving work efficiency, and safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

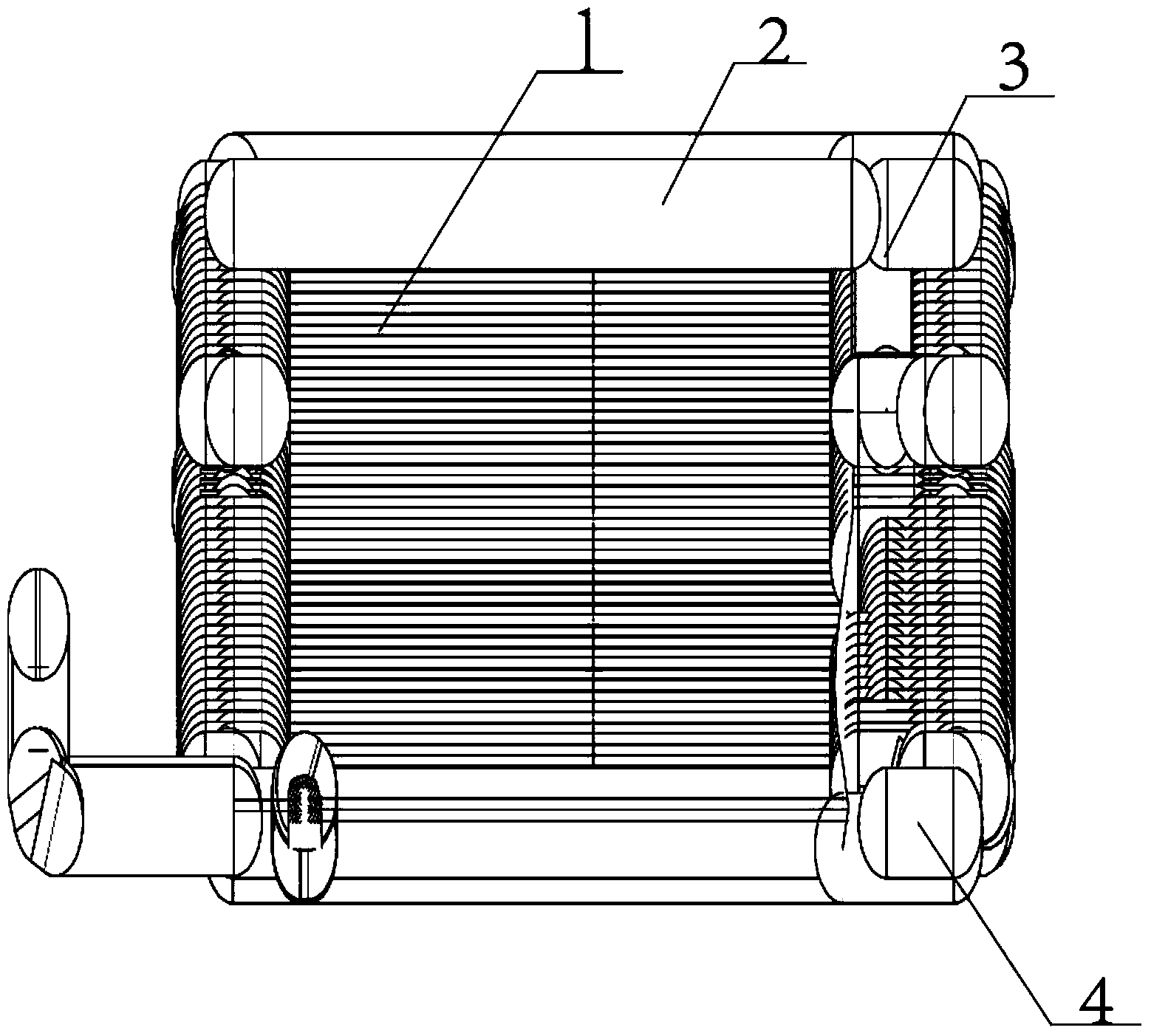

[0019] Take the 6000KW high-speed transformation unit as an example: figure 1 It is a schematic diagram of the improved magnetic pole coil design, including: copper bar 1, insulating support plate 2, epoxy glass cloth plate 3 and F-grade epoxy glass cloth rod insulating pin 4, characterized in that: the copper bar 1 is arranged on the coil Inside, the shape of the copper bar 1 is rectangular, the insulating wire supporting plate 2 is arranged on the upper end of the coil, the insulating wire supporting plate 3 and the copper bar 1 are fixedly connected to each other, and the epoxy glass cloth plate 3 is arranged on the insulating supporting plate 2- On the side, the epoxy glass cloth board 3 and the copper bar 1 are fixedly connected to each other, the F-grade epoxy glass cloth rod insulating pin 4 is arranged at the lower end of the copper bar 1, and the F-class epoxy glass cloth rod insulating pin 4 is connected to the copper bar 1 Fixed connection. The 6000KW high-speed re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com