Compressor pulley assembly and method for manufacturing same

A manufacturing method, compressor technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of reducing the total weight and restrictions of pulley components, to enhance wear resistance and prevent idling , to ensure the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] best practice

[0049] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

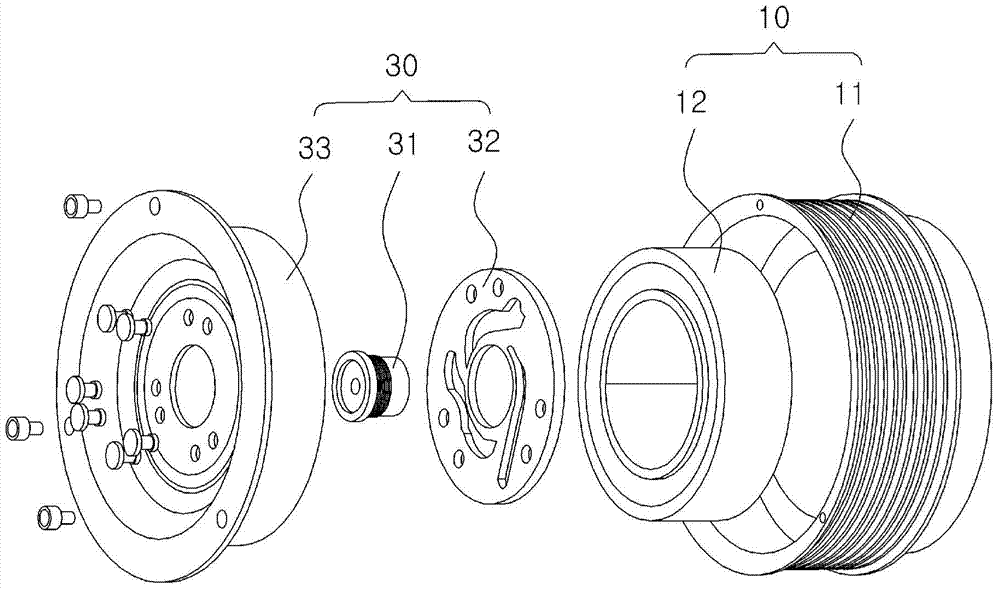

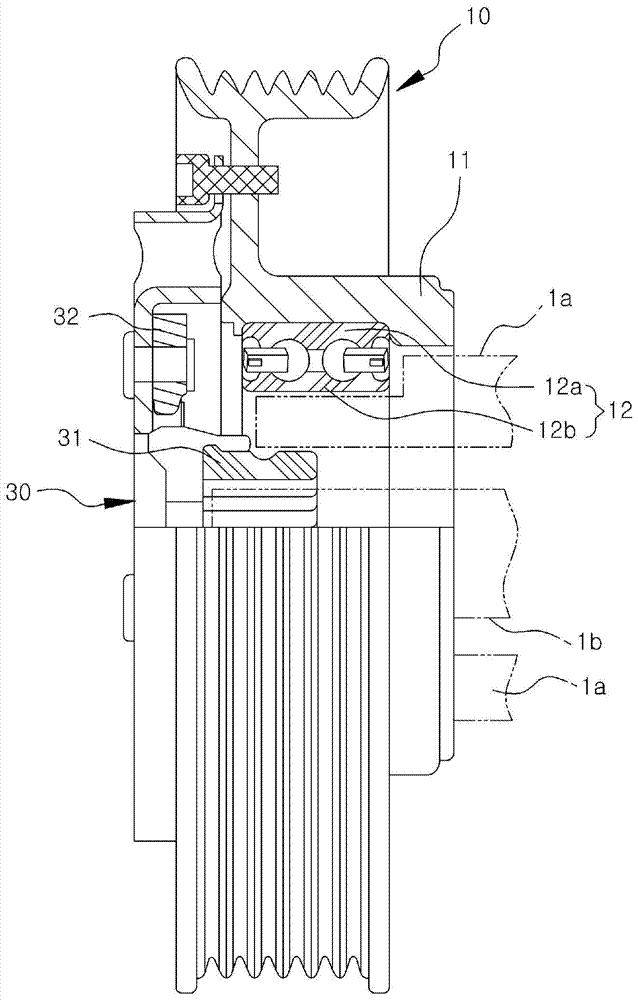

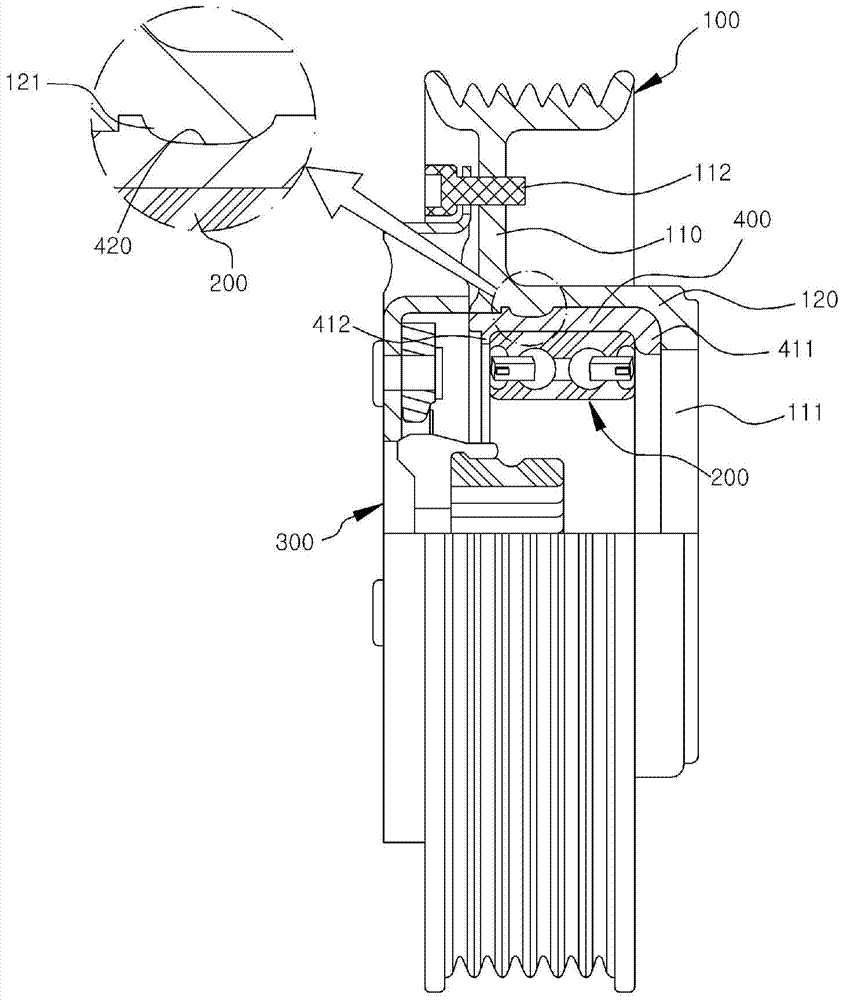

[0050] image 3 is a partial sectional view showing an internal structure of a pulley assembly of a compressor according to a preferred embodiment of the present invention.

[0051] As shown in the drawings, a pulley assembly of a compressor according to a preferred embodiment of the present invention includes a pulley 100 , a bearing 200 and an inner ring 400 .

[0052] The components of the pulley assembly will be described in detail as follows.

[0053] First, the pulley 100 receives driving force from an engine. The pulley 100 is in the form of a hollow cylinder, and is connected to an outer peripheral surface of the pulley 100 by a motor-driven belt (not shown in the drawings).

[0054] Specifically, pulley 100 is made of magnesium alloy.

[0055] The pulley 100 includes: a partition wall 110 formed in the pulley ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com