Portrait urn and its processing technology

A technology for urns and portraits, applied in the field of 3D printing, can solve problems such as immature technology, and achieve far-reaching social benefits, no land occupation, and wood saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

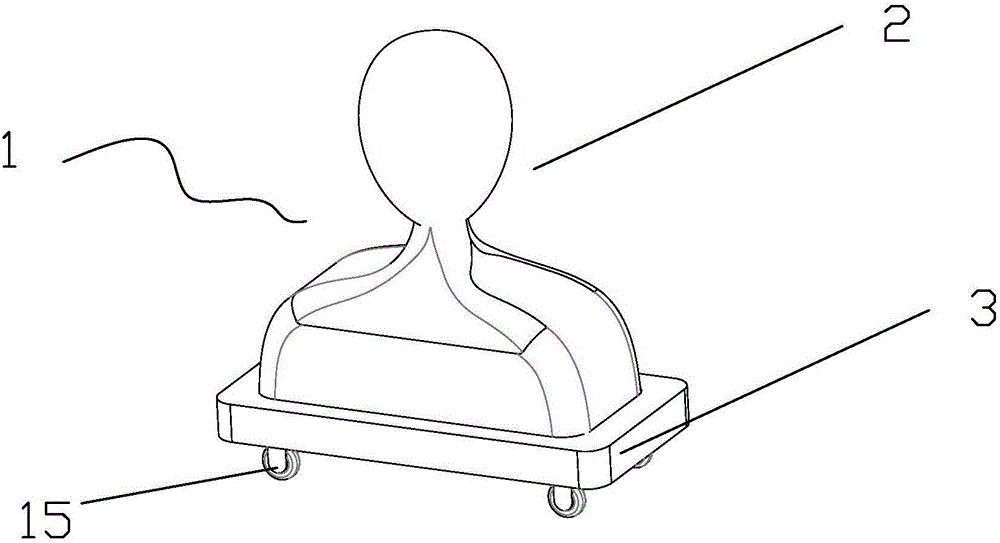

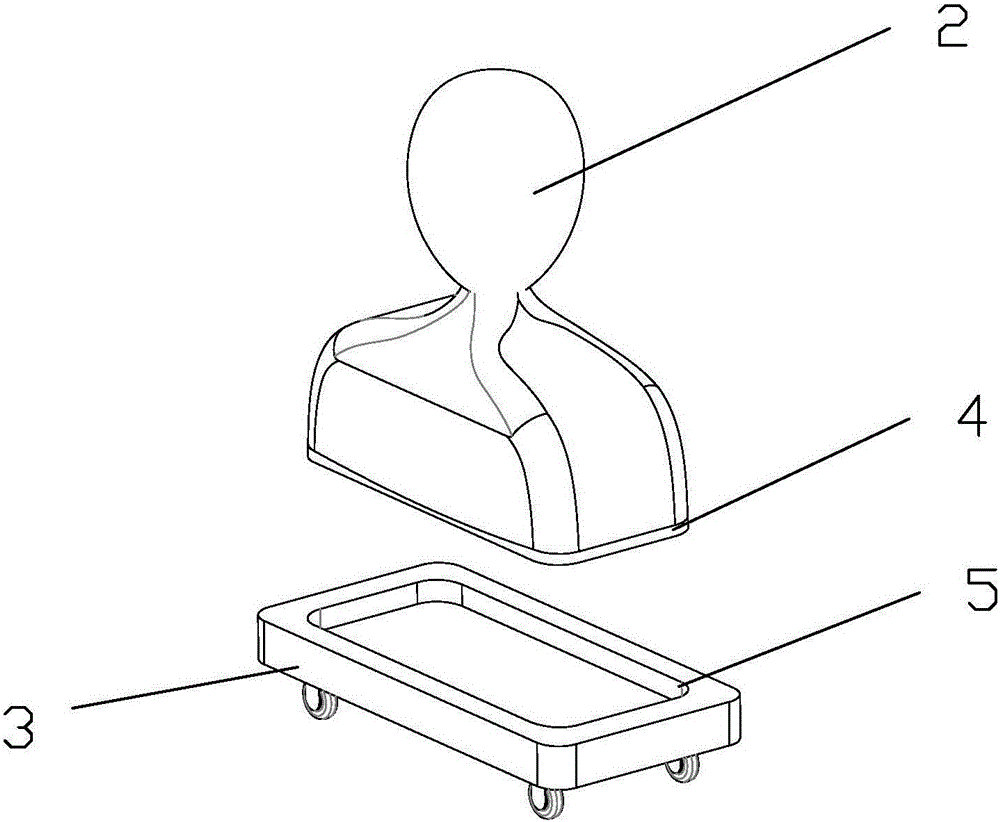

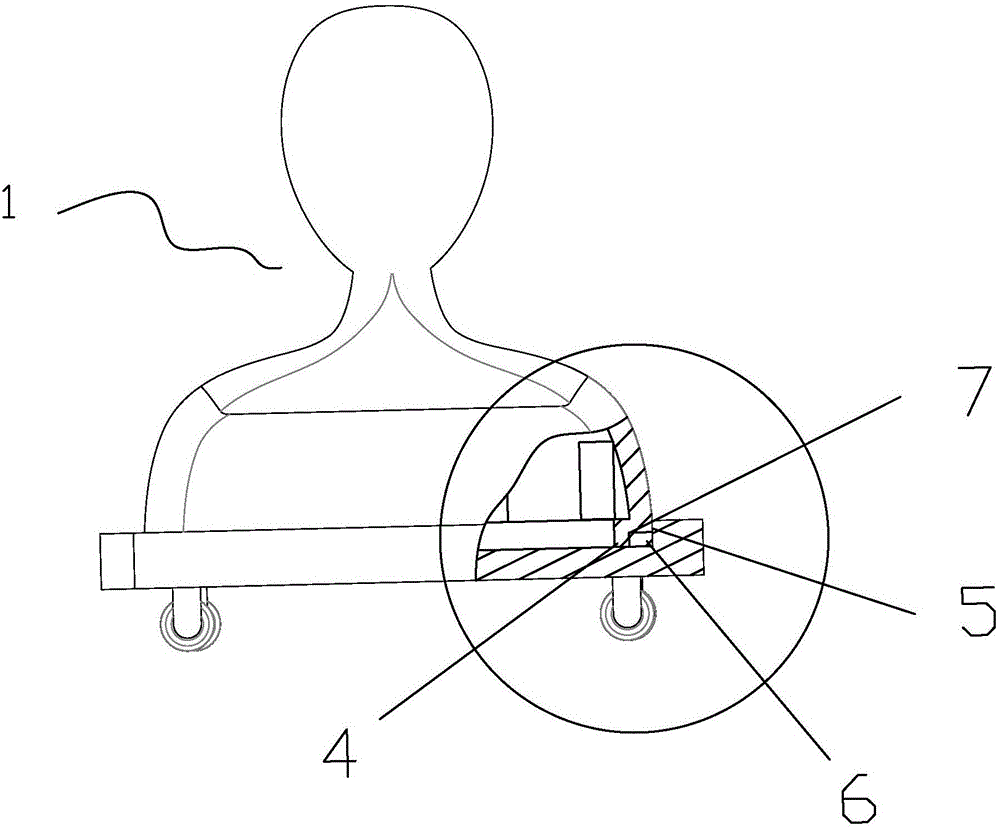

[0059] Such as figure 1 Or the portrait urn 1 shown in 2, including the portrait 2, the base 3 and the power unit, the portrait 2 has a chest cavity inside, the portrait urn 1 is made of ABS material, and the bottom edge of the portrait 2 is along the circumference. The rib 4 and the top of the base 3 are provided with a groove 5 along the circumference, and the rib 4 and the groove 5 are closely fitted together. Among them, the facial and physical features of portrait 2 are the same as those of the deceased (not shown in the figure).

[0060] combine Figure 9 As shown, the power unit includes a remote control receiving assembly and a power unit. The remote control receiving assembly includes a circuit board 12 and a single chip microcomputer, a power supply module and a wireless receiving module 13 arranged on the circuit board. The power unit includes a motor 14 and a pulley 15 . A remote controller (not shown in the figure) can control the remote control receiving compon...

Embodiment 2

[0062] Such as image 3 and 4 The portrait urn shown is basically the same as that of Embodiment 1. The difference from Embodiment 1 is that this portrait urn 1 is also provided with a sealing rubber ring 6 and a second cavity 8, wherein the rib 4 has a bend 7, The bending arrangement makes it form an annular area with the groove 5, and the sealing rubber ring 6 is located in the above-mentioned annular area, so that the seal between the portrait 2 and the base 3 is more reliable.

[0063] The root of the second cavity 8 is arranged on the portrait 2 to be connected, and is arranged on the top inside of the first cavity of the portrait (2). The appearance of the portrait urn is a spray paint layer.

Embodiment 3

[0065] Such as Figure 5 The portrait urn shown is basically the same as the embodiment 2, the difference is: the root of the second cavity 8 is set on the bottom cover of the portrait 2 . The appearance of the portrait urn is an electroplating layer.

[0066] A magnetic anchor device is also provided, and the magnetic anchor device 11 is arranged on the base 3 . There is also a strong magnet (not shown) inside the device, which can be adsorbed on the metal platform to prevent it from being lost, and it is also more stable to place. The exterior of the portrait urn is copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com