Rectifying apparatus for producing ethyl octanoate

A technology for the production of ethyl octanoate and rectification, which is applied in the field of rectification equipment for the production of ethyl octanoate, can solve the problems of heating energy consumption, unfavorable energy saving, etc., and achieve the effects of reduced reaction time, simple structure and large energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

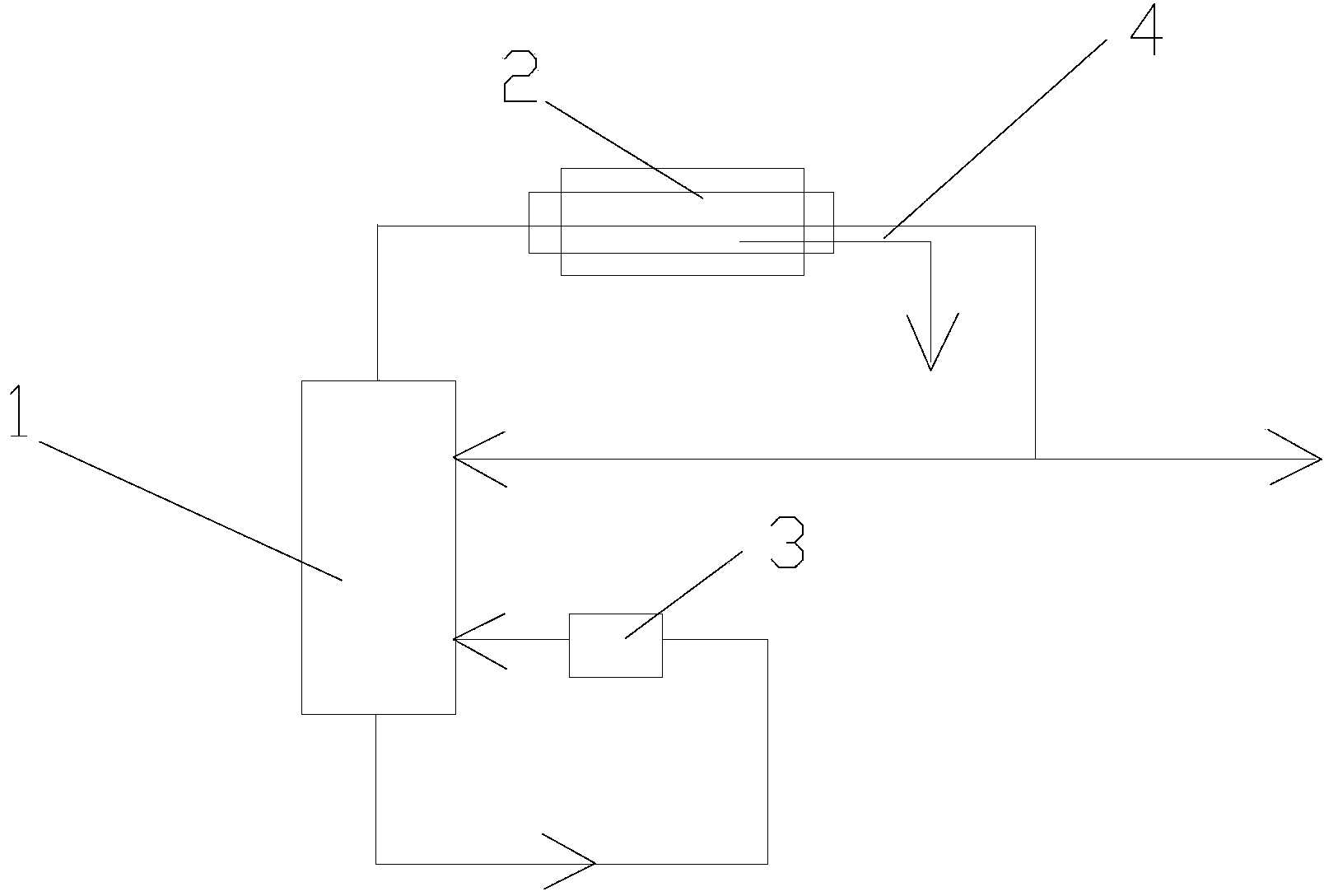

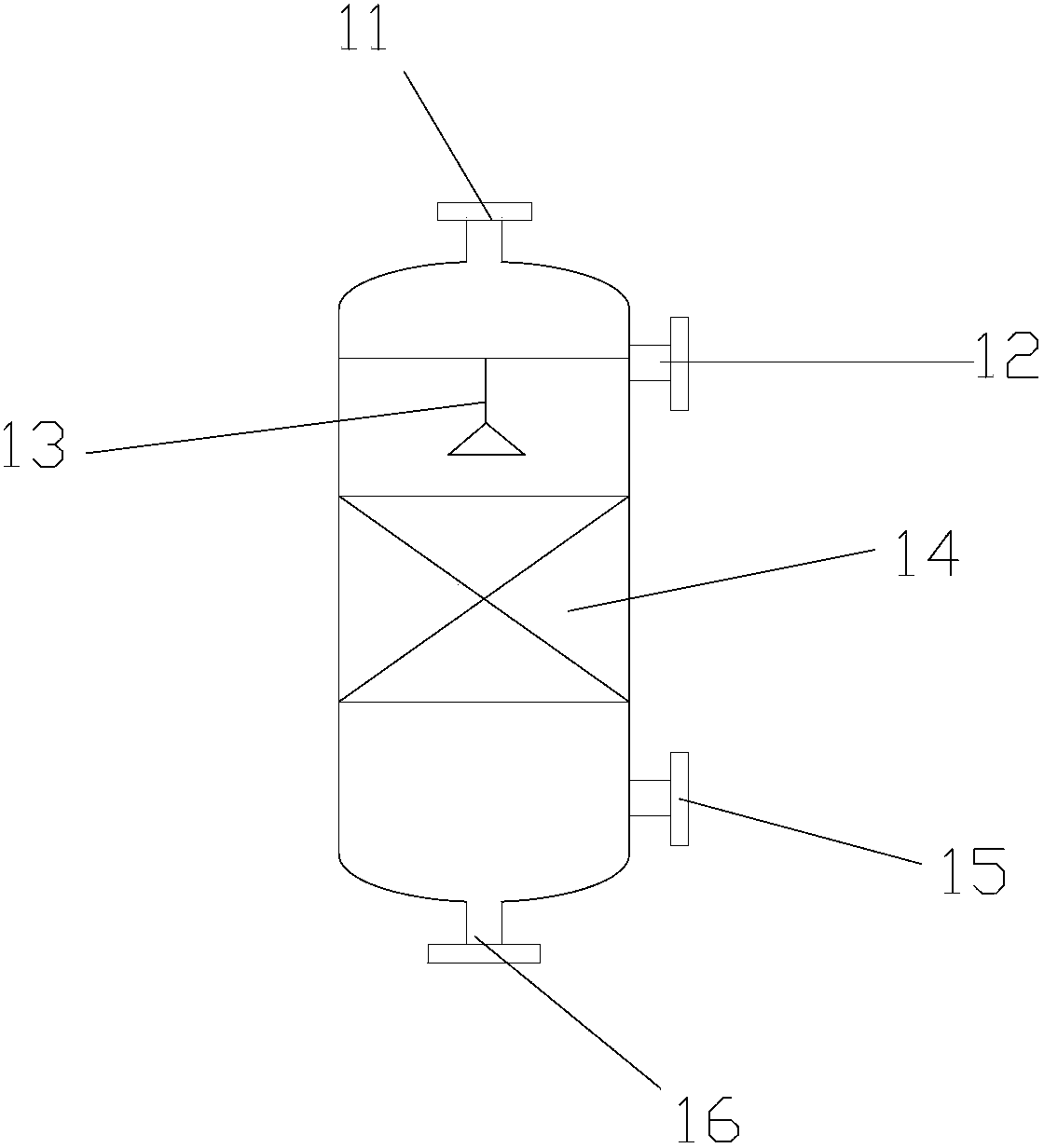

[0015] The rectifying device for producing ethyl octanoate includes a rectifying tower body 1, a reboiler 3 and a condenser 2, and a guide pipe 4 is also provided at the outlet of the condenser, and the guide pipe is in the form of " L" type. The top of the rectifying tower is provided with a steam outlet 11, a reflux liquid inlet 12 is provided on the side below the steam outlet, and the reflux liquid inlet is connected to a spray device 13, a filler 14 is arranged under the spray device, and a reboiler is arranged at the lower end of the filler The return port 15 is provided with a material inlet port 16 at the bottom of the rectification tower. The packing is metal corrugated structured packing, and the condenser is a tubular heat exchanger. A diversion pipe is arranged at the outlet of the condenser. Since the product ethyl octanoate is insoluble in water, its mass is lighter than that of water, and the condensate at the outlet of the condenser is water-oil two-phase. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com