Belt type lattice flow rice husking machine and rice husking method

A rice milling machine and separation technology, applied in grain processing, application, grain pod removal, etc., to achieve the effect of reducing broken rice rate, good rice milling effect, and low single-machine power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

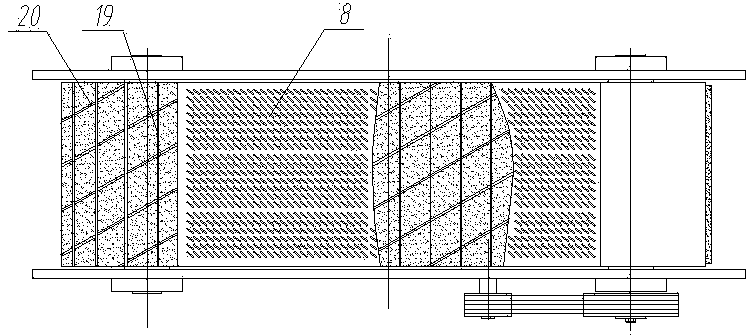

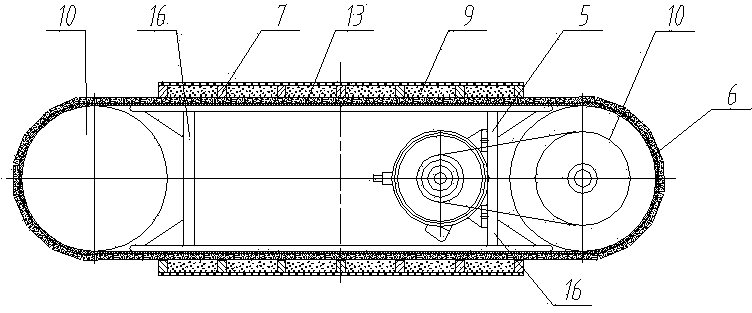

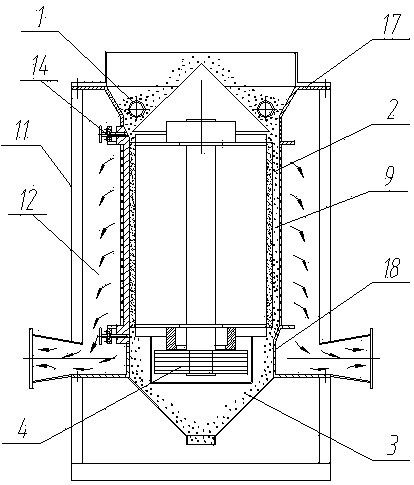

[0031] Belt-type separated flow rice milling machine, its composition includes: feeding device 1, whitening chamber 2, discharge device 3, transmission device 4 and frame 5, and described whitening chamber comprises oppositely arranged, by milling belt 6. Two groups (rows) of rice milling rooms 9 surrounded by spacers 7 and rice sieves 8. The milling belt goes around the rollers 10 at both ends of the frame to form an endless belt. The spacers The distance between the grinding belt and the milling belt is less than 2 mm. The rice sieve is installed on the outside of the spacer, and there is a negative pressure space 12 between the outside of the rice sieve and the shell 11. The negative pressure The pressure space is connected to the suction fan.

Embodiment 2

[0033] In the belt-type split-flow rice mill described in Embodiment 1, the rice milling rooms are arranged along the milling belt, and the overall layout is oblong.

Embodiment 3

[0035] In the belt-type split-flow rice mill described in embodiment 1 or 2, the described grinding belt is a flat belt or chain with a grinding sheet installed, and the described grinding sheet is strip-shaped and fixed on the flat plate On the belt or chain, the grinding sheet 13 is a sand board or a metal grinding board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com