Vehicular sound-absorption and thermal-insulation material, preparation method of vehicular sound-absorption and thermal-insulation material, and prepared vehicular sound-insulating pad

A technology of thermal insulation material and sound insulation pad, applied in chemical instruments and methods, vehicle parts, lamination and other directions, can solve the problems of aging, high cost, low sound absorption performance, etc., to meet the flame retardant performance, improve sound absorption performance, sound absorption The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

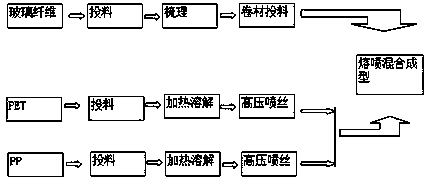

Method used

Image

Examples

Embodiment 1

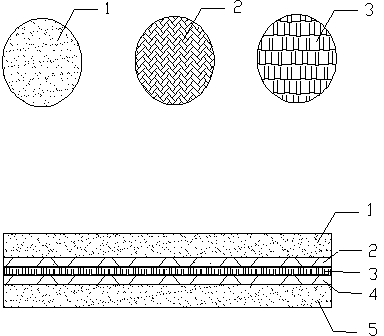

[0027] Example 1: Please refer to the attached figure 1 , a sound-absorbing and heat-insulating material for vehicles, the components of the sound-absorbing and heat-insulating material include: glass fiber 1, PP fiber 2, and PET fiber 3; the sound-absorbing and heat-insulating material is divided into five layers, which are: Glass fiber layer; the second layer 2 is a mixed fiber of glass fiber, PP fiber and PET fiber; the middle layer 3 is a mixed fiber of PP material and PET; the fourth layer 4 is a combination of glass fiber, PP fiber and PET fiber The mixed fiber; the surface layer 5 is glass fiber; the five layers are melted and connected into one.

[0028] In this embodiment, the weight ratio of the glass fiber 1 , the PP fiber 2 and the PET fiber 3 is: glass fiber 1 : PP fiber 2 : PET fiber 3 =6:2:2.

[0029] In this embodiment, the weight percentage of glass fiber 1 is 60%; the weight percentage of PP fiber 2 is 20%; the weight percentage of PET fiber 3 is 20%.

[...

Embodiment 2

[0031] Example 2: A sound-absorbing and heat-insulating material for vehicles. The components of the sound-absorbing and heat-insulating material include: PP, PET, and glass fiber; the sound-absorbing and heat-insulating material is divided into five layers, which are: bottom glass fiber; the second layer is The mixed fiber of glass fiber, PP fiber and PET fiber; the middle layer is the mixed fiber of PP material and PET; the fourth layer is the mixed fiber of glass fiber, PP fiber and PET fiber; the surface layer is glass fiber; The layers are fused into one.

[0032] In this embodiment, the weight ratio of the glass fiber, PP and PET is: glass fiber:PP:PET=8:1:1.

[0033] In this embodiment, the weight percentage of the glass fiber is 80%; the weight percentage of PP is 10%; the weight percentage of PET is 10%.

[0034]In this embodiment, the diameter of the glass fiber is between 7-11 μm, and the length is between 45-70 mm; the PP is fibrous, and the diameter of the PP f...

Embodiment 3

[0035] Example 3: A sound-absorbing and heat-insulating material for vehicles. The components of the sound-absorbing and heat-insulating material include: PP, PET, and glass fiber; the sound-absorbing and heat-insulating material is divided into five layers, which are: bottom glass fiber; the second layer is The mixed fiber of glass fiber, PP fiber and PET fiber; the middle layer is the mixed fiber of PP material and PET; the fourth layer is the mixed fiber of glass fiber, PP fiber and PET fiber; the surface layer is glass fiber; The layers are fused into one.

[0036] In this embodiment, the weight percentage of the glass fiber is 60%; the weight percentage of PP is 20%; the weight percentage of PET is 20%.

[0037] In this embodiment, the glass fiber has a diameter of 7-μm and a length of 45 mm; the melt-blown PP fiber has a diameter of 4 μm and a length of 40 mm; the melt-blown PET fiber has a diameter of 4 μm and a length of 40 mm.

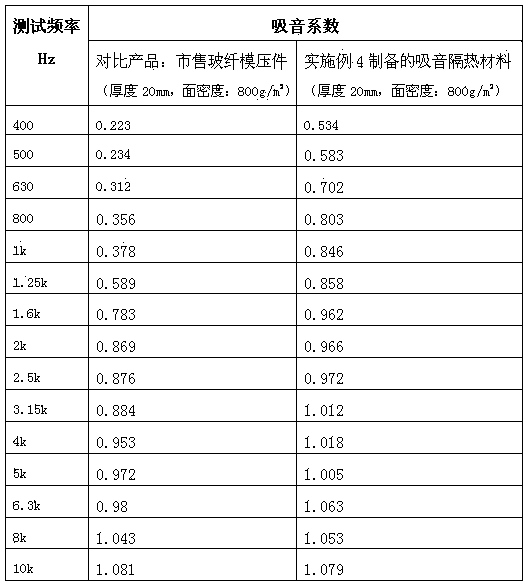

[0038] The car uses sound-absorbing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com