The Method of Partially Damaged Coke Oven Hot Repair Carbonization Chamber Wall

A carbonization chamber and coke oven technology, applied in the direction of preventing/repairing the leakage of bricklaying, can solve the problems of excessive gas and toxic gas content, expanding the scope of digging and repairing, and wall bursting, etc., to reduce the probability of safety accidents and protect people. Safety and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with specific implementation, the embodiment of the present invention is further described:

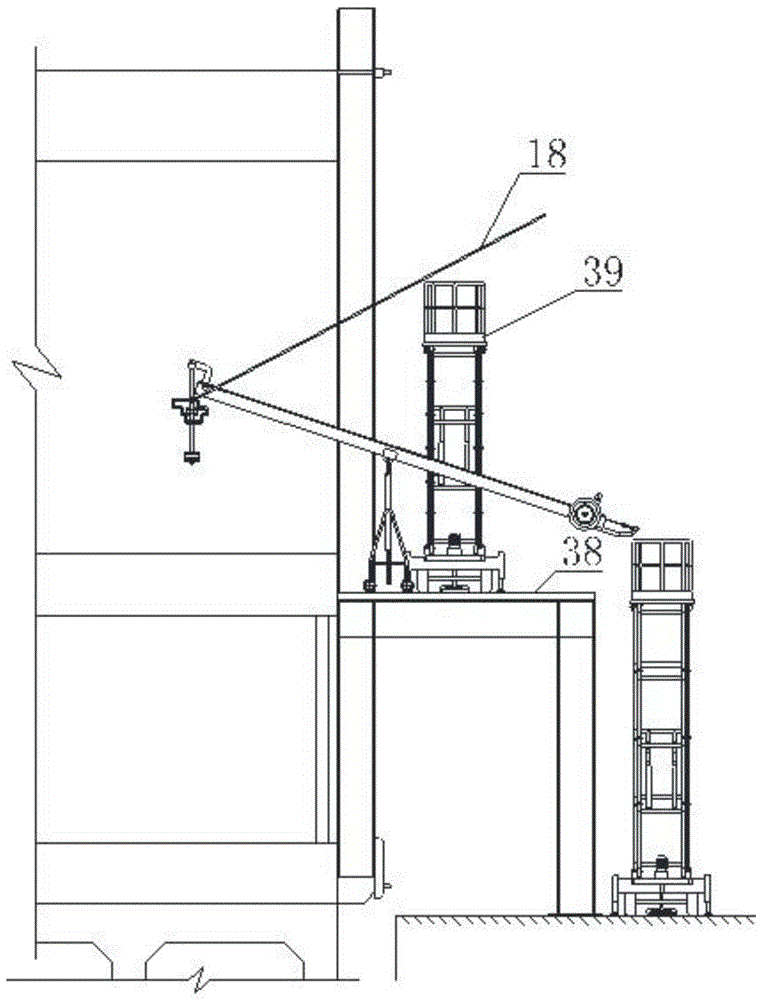

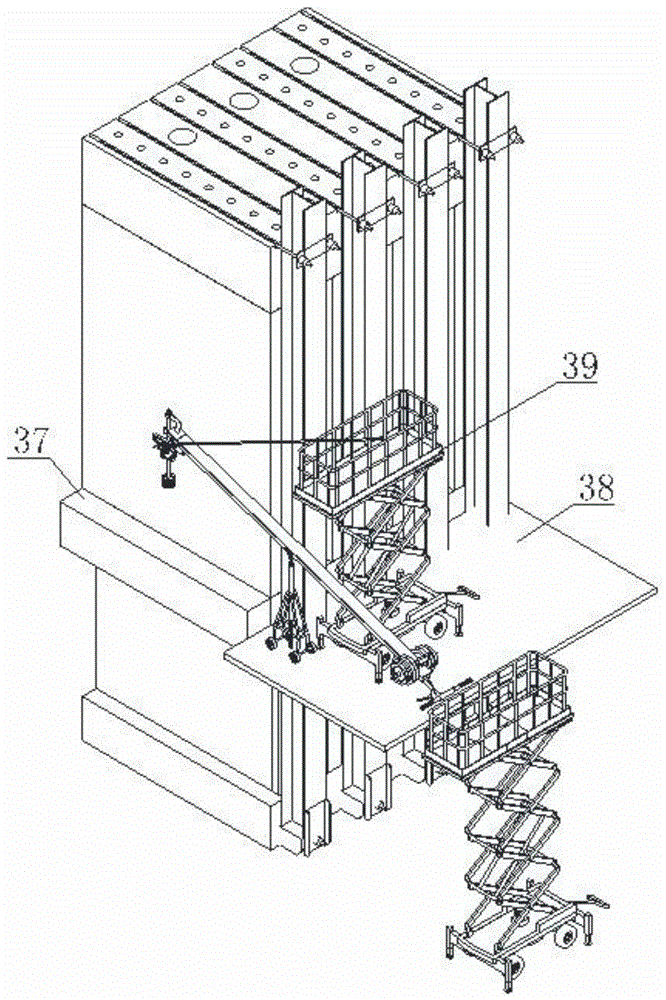

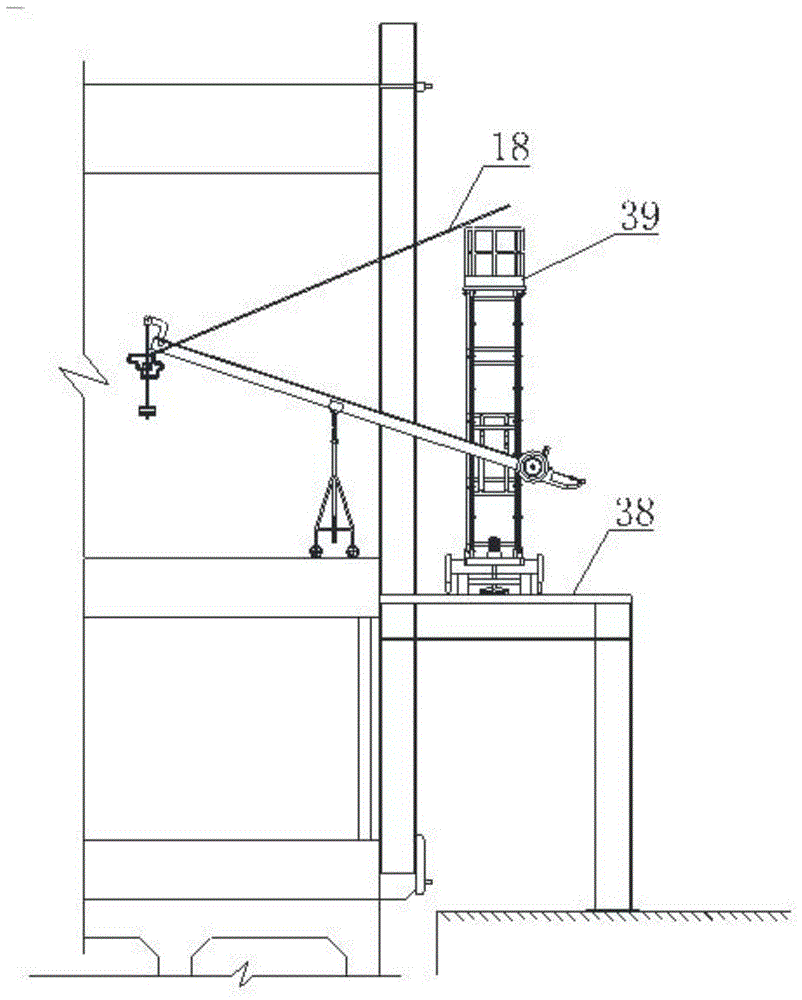

[0038] like Figure 1 to Figure 11 The hole repair device on the wall of the carbonization chamber shown, such as Figure 5 to Figure 11 As shown, it is mainly composed of a rocker arm 1, an image acquisition system, a spraying device, a filling brick clamp and a rocker movable support frame, wherein one end of the rocker arm 1 is provided with a hand handle 2, a counterweight bar 3 and a monitor 5, A counterweight 4 is provided on the counterweight bar, and a brick clamp opening and closing handle 6 is provided on the hand handle 2; a boom seat 10 is provided at the other end of the rocker arm 1, and the boom seat is connected to the boom 12 through the boom connector 11. The shaft is connected; the two sides of the boom are respectively equipped with spraying devices and brick filling clips; the middle part of the rocker arm is equipped with a rocker mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com