A general circuit board testing system

A test system and circuit board technology, applied in the direction of electronic circuit testing, etc., can solve the problems of low degree of automation, complicated operation process, non-universal, etc., and achieve the effect of high degree of automation, strong expandability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

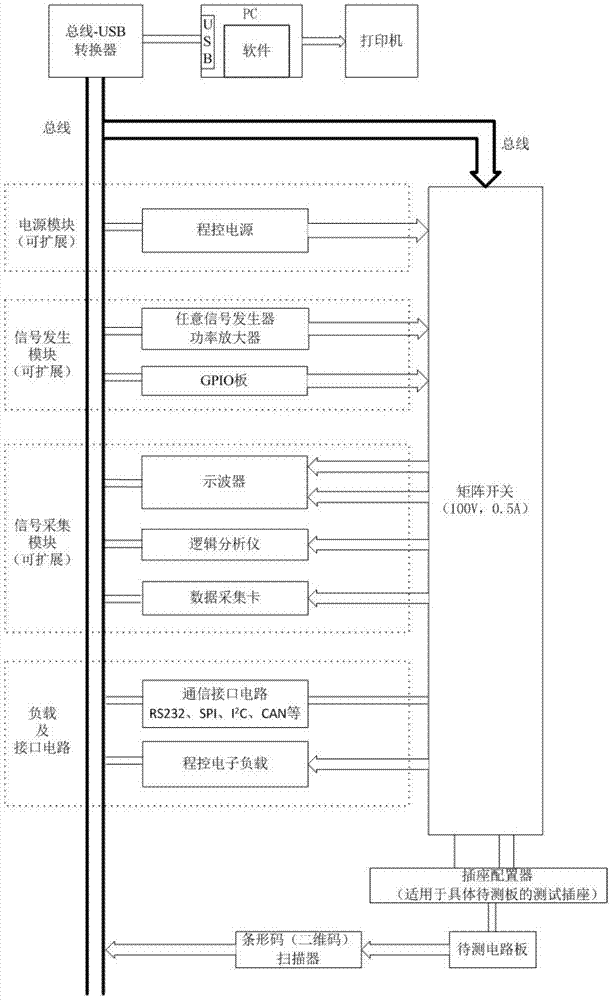

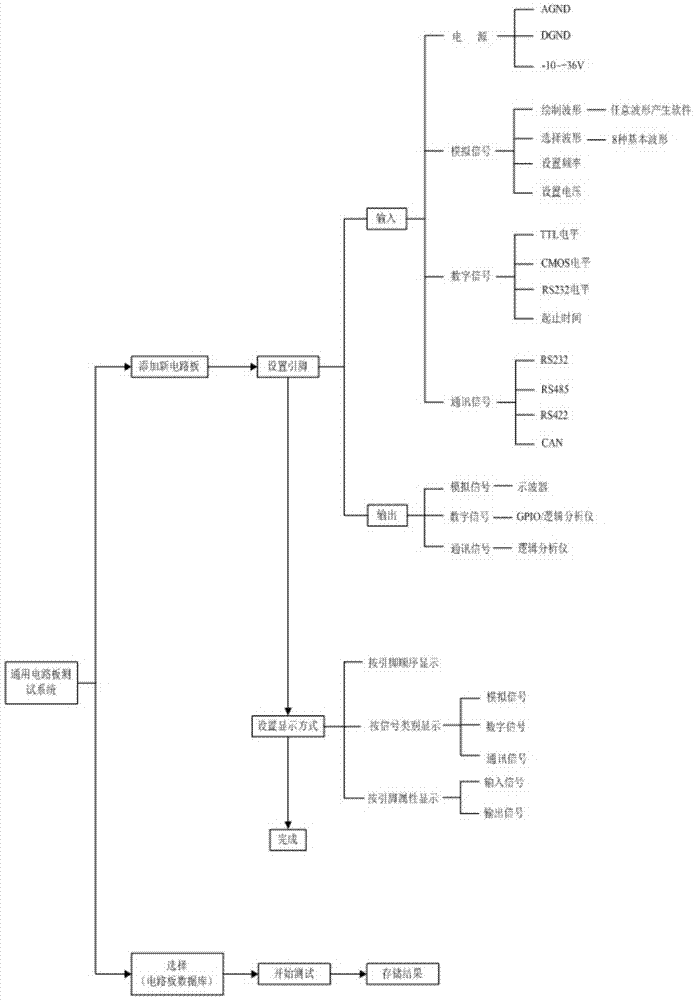

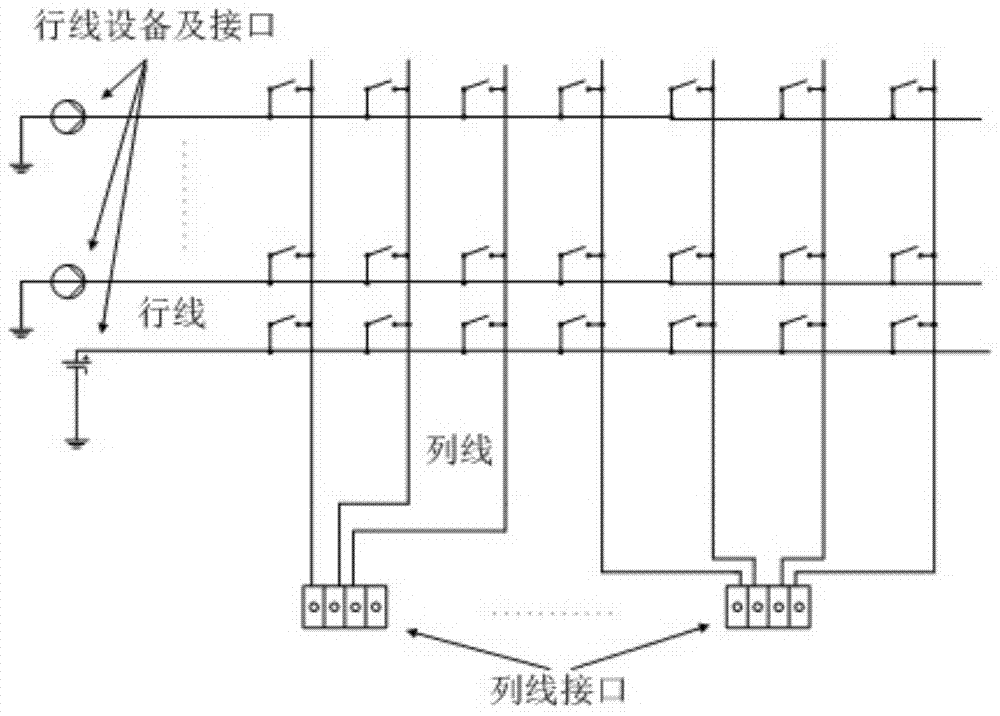

[0027] like Figure 1 to Figure 3 As shown, the general-purpose circuit board testing system described in this embodiment includes two parts, a test machine and a test software, wherein the test machine is used to complete all the hardware of the test task, and has a maximum of 32*32 matrix, row The line and column line can be connected to 32 input and output signals respectively. All hardware parts in the test machine can be expanded or reduced according to actual needs. The test machine includes an automatic test resource and a matrix switch, and the automatic test resource includes an expandable power supply module, an expandable signal generation module, an expandable signal acquisition module, a barcode (two-dimensional code) scanner, and a socket configuration Devices, loads and interface circuits are used to generate stimulus signals and test and analyze response sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com