Combined electric welding and power generating dual-purpose machine

A combined, generator stator technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of poor power generation and electric welding, simultaneous use, inability to generate electricity and electric welding, etc., to achieve low temperature rise, convenient The effect of disassembly, repair and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

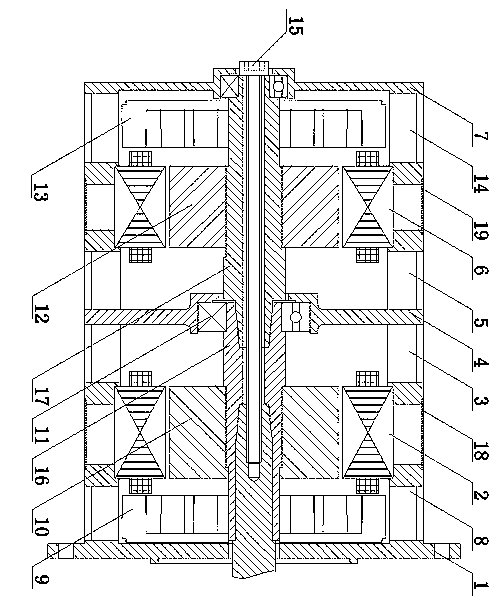

[0008] figure 1 Shown: front end cover 1 is fixed on the body of engine by fixing bolt. The generator stator 2 and the intermediate connection end cover 4 are fixed on the front end cover 1 through external long bolts, and a cylindrical shell 18 is placed between the intermediate end cover 4 and the front end cover 1; The full-length bolts are fixed on the intermediate connecting end cap 4, and a cylindrical shell 19 is placed between the rear end cap 7 and the intermediate connecting end cap 4. Finally, it forms a whole with the engine.

[0009] The generator rotor 10 is fixed on the generator rotor shaft 16; the electric welding machine rotor 12 is fixed on the electric welding machine rotor shaft 17, and the electric generator rotor shaft 16 and the electric welding machine rotor shaft 17 are fixed on the engine shaft by through-hole bolts 15, for To avoid shaft rotation deformation and vibration, support bearings 11 are arranged near the joint of the two shafts, fan blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com