Humectant as well as preparation method and application thereof

A humectant and preservative technology, applied in the field of moisturizer and its preparation, can solve the problems of insufficient moisturizing effect of moisturizer, unsatisfactory moisturizing effect of women, insufficient moisturizing effect of cosmetics, etc., and achieve good skin-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

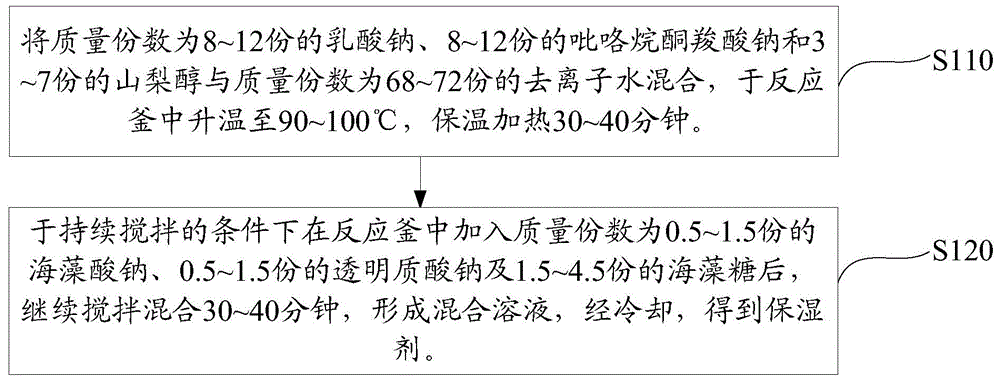

[0031] Such as figure 1 As shown, the preparation method of a moisturizer according to one embodiment can be used to prepare the above moisturizer. The preparation method of this humectant comprises the steps:

[0032] Step S110: mix 8-12 parts by mass of sodium lactate, 8-12 parts by mass of sodium pyrrolidone carboxylate and 3-7 parts of sorbitol with 68-72 parts by mass of deionized water, and place in a reaction kettle Warm up to 90-100°C in medium temperature, keep warm and heat for 30-40 minutes.

[0033] Specifically, in step S110, sodium lactate, sodium pyrrolidone carboxylate and sorbitol are added to deionized water. It can be understood that sodium lactate, sodium pyrrolidone carboxylate and sorbitol can also be added to the reaction kettle first, and then deionized water can be added.

[0034] After mixing sodium lactate, sodium pyrrolidone carboxylate, sorbitol and deionized water, raise the temperature to 90-100°C, keep warm and heat for 30-40 minutes to disso...

Embodiment 1

[0044] The preparation method of the moisturizing agent of the present embodiment is as follows:

[0045] The reactor was cleaned with deionized water, then 72 parts by mass of deionized water were added to the reactor, followed by 8 parts of sodium lactate, 12 parts of sodium pyrrolidone carboxylate and 7 parts of Sorbitol, and then the reactor was heated to 90° C., kept warm for 40 minutes, and the heating was stopped to obtain a mixed solution.

[0046]Start the stirring device in the kettle, and add 0.5 parts of sodium alginate, 1.5 parts of sodium hyaluronate and 1.5 parts of trehalose into the reaction kettle under the condition of continuous stirring at a stirring rate of 50 rpm , and continue stirring and mixing at a stirring rate of 50 rpm for 30 minutes, then carry out internal circulation in the reactor for 2 times, and then pass through condensed water to cool until the temperature in the reactor is cooled to 40°C, adding 0.3 parts by mass 100% preservative, where...

Embodiment 2

[0048] The preparation method of the moisturizing agent of the present embodiment is as follows:

[0049] Clean the reactor with deionized water, then add 70 parts by mass of deionized water into the reactor, then add 10 parts by mass of sodium lactate, 10 parts of sodium pyrrolidone carboxylate and 3 to 7 part of sorbitol, and then the reactor was heated to 95° C., kept warm for 35 minutes, and the heating was stopped to obtain a mixed solution.

[0050] Start the stirring device in the kettle, and add 1 part of sodium alginate, 1 part of sodium hyaluronate and 3 parts of trehalose into the reaction kettle under the condition of continuous stirring at a stirring rate of 60 rpm , and continue stirring and mixing at a stirring rate of 60 rpm for 35 minutes, then carry out internal circulation in the reactor for 3 times, and then pass through condensed water to cool until the temperature in the reactor is cooled to 40°C, adding 0.5 parts by mass part of phenoxyethanol and stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com