Gluing device and method of special glue body for terminal lug of aerial circuit breaker

A glue coating device and circuit breaker technology, which is applied to the device and coating of the surface coating liquid, which can solve the problem of short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

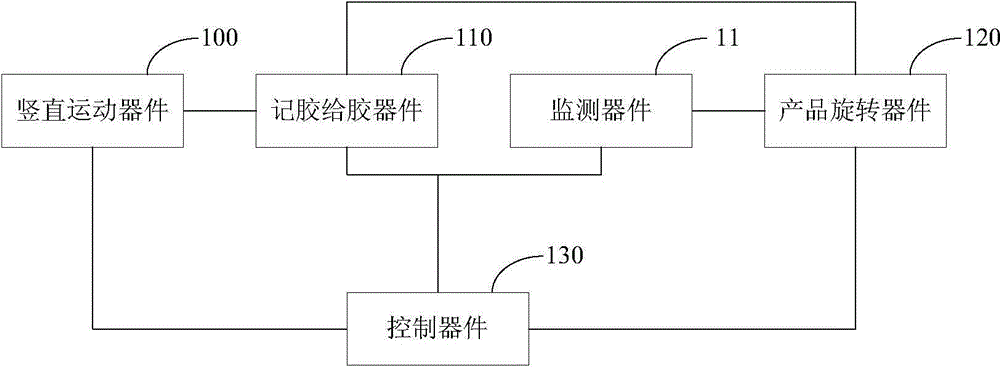

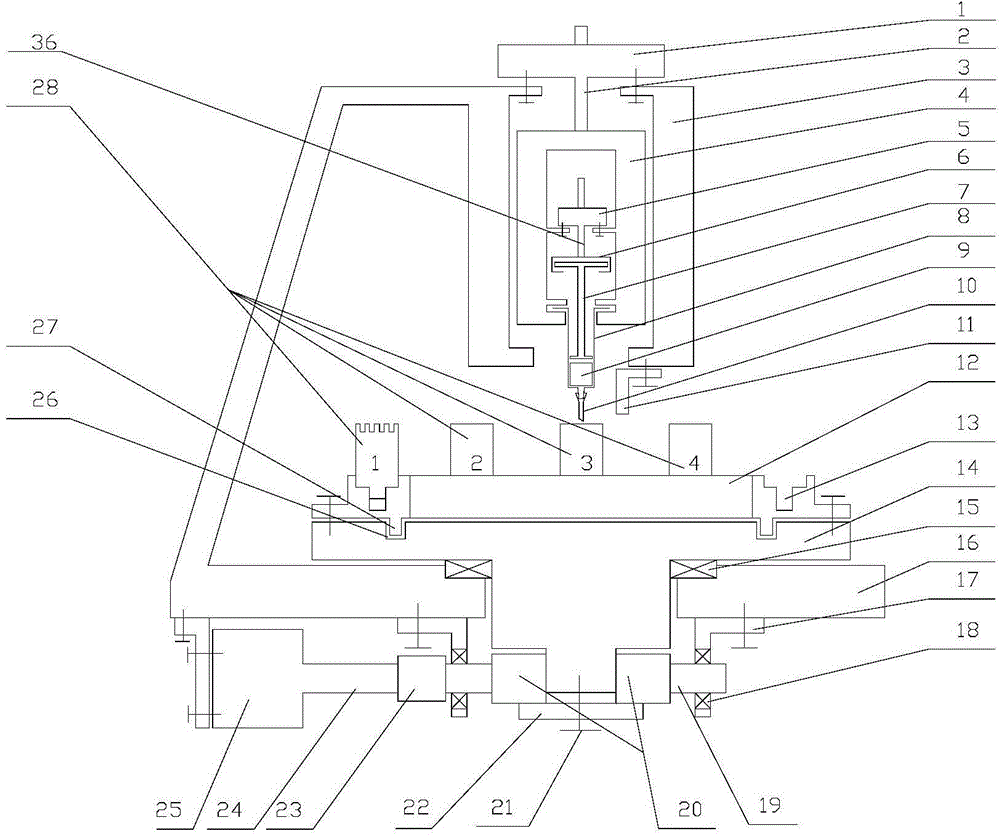

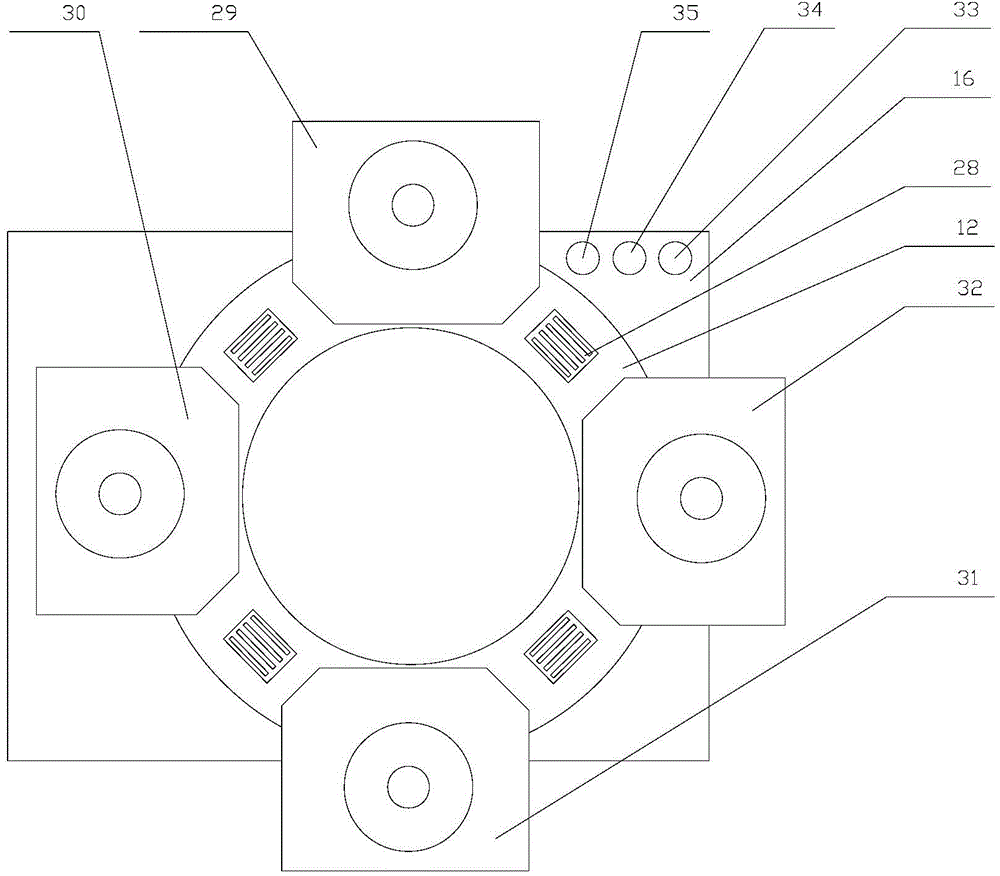

[0046] figure 1 It is a block diagram of the structure of the gluing device for the special glue for aviation circuit breaker lugs provided by the first embodiment of the present invention; refer to figure 1 As shown, the gluing device for special colloid for aviation circuit breaker lugs includes multiple sets of executive gluing mechanisms, product rotation devices 120 and control devices 130 arranged on the horizontal frame 16; the executive gluing mechanism includes: Vertical movement device 100, glue recording device 110 and detection device 11;

[0047] The vertical movement device 100 is used to drive the glue-feeding device 110 to move vertically;

[0048] The glue-recording and glue-feeding device 110 is used to apply glue to the product according to the set glue-feeding amount and break the glue when the glue-coating is completed;

[0049] The detection device 11 is used to detect whether the product 28 to be glued reaches the station corresponding to the designate...

no. 2 example

[0070] Pic 4-1 It is a flow chart of the glue application method for aviation circuit breaker lug special glue provided by the second embodiment of the present invention. refer to Pic 4-1 Shown, described gluing method comprises the steps:

[0071] Step S410, pouring glue;

[0072] Step S420, transporting the product 28 to be glued;

[0073] Step S430, judging whether there is a product 28 to be glued at the work station to be glued;

[0074] Step S440 , according to the judgment result, perform glue coating and glue cutting operations or drive the rotary table 14 to rotate until the product 28 to be glued rotates to the working station to be glued.

[0075] refer to Figure 4-2 As shown, further, the specific optimization of performing the gluing, gluing operation or driving the rotary table 14 to rotate until the product 28 to be gluing is rotated to the gluing operation station according to the judgment result is as follows:

[0076] Step S441, when it is detected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com