Durable antistatic anti-explosion packing bag and preparation method thereof

An anti-static and durable technology, applied in the field of anti-static explosion-proof packaging bags and their preparation, can solve the problems of reduced anti-static performance, disappearance, weakened anti-static ability, etc., and achieves good anti-static ability, good durability, and easy volatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

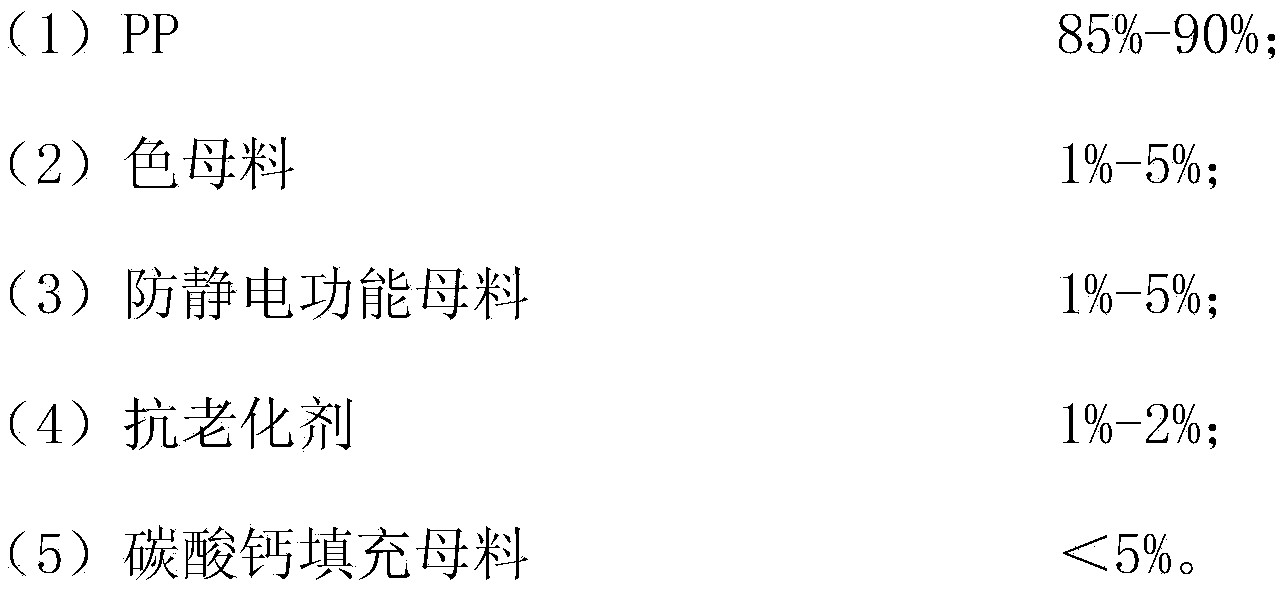

[0035] A kind of durable antistatic explosion-proof packaging bag of the present invention, it comprises the component composition of following percentage,

[0036]

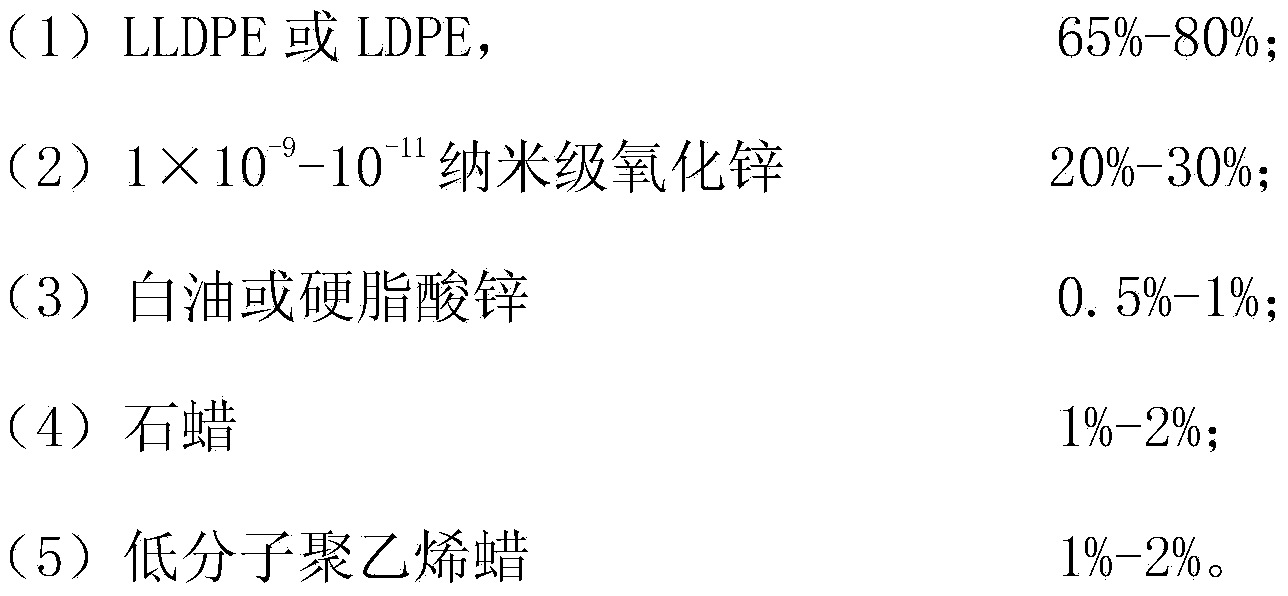

[0037] The antistatic functional masterbatch includes the following percentage components,

[0038]

[0039] A preparation method of durable antistatic explosion-proof packaging bag, it comprises the following steps,

[0040] (1) Wire drawing: each raw material particle is sucked by the automatic suction device of the wire drawing machine according to the above ratio, and stirred; the raw material after stirring is melted and extruded by the wire drawing machine to form a film, and its melting temperature is 230 ° C, and its pressure At 8Kg; the above-mentioned film is cooled by a water tank, and the temperature of the cooling water is 40°C; the cooled film is divided by a knife row to form a monofilament; the monofilament is stretched by an oven and a traction roller, and the oven temperature is 140 ℃, th...

Embodiment 2

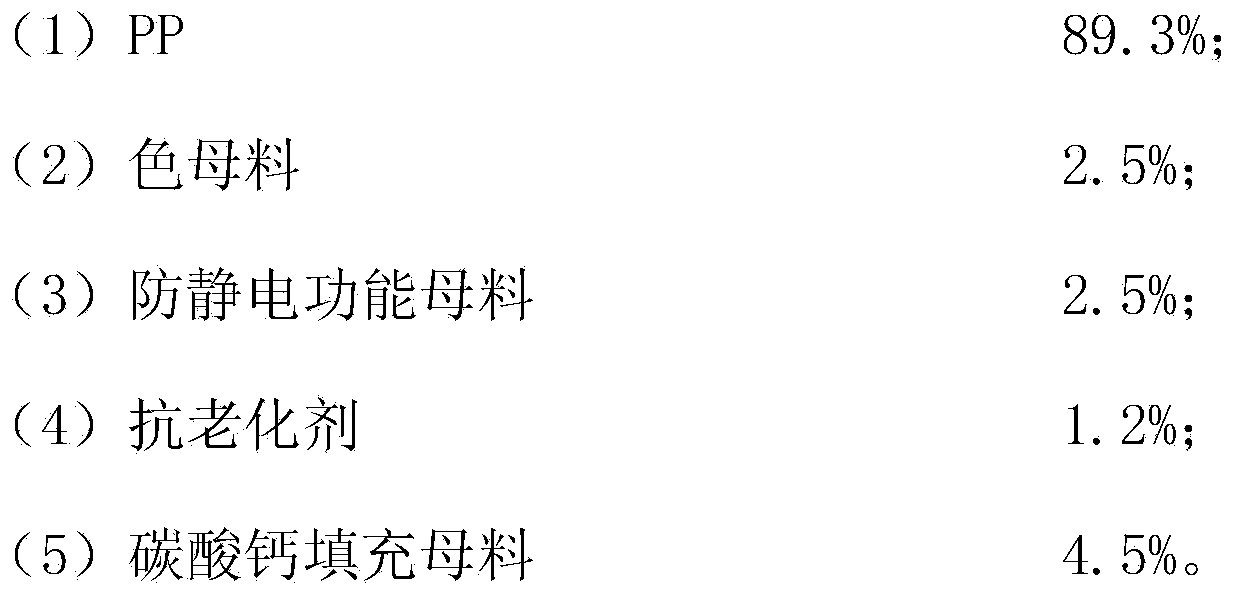

[0046] A kind of durable antistatic explosion-proof packaging bag of the present invention, it comprises the component composition of following percentage,

[0047]

[0048] The antistatic functional masterbatch includes the following percentage components,

[0049]

[0050]

[0051] A preparation method of durable antistatic explosion-proof packaging bag, it comprises the following steps,

[0052] (1) Wire drawing: each raw material particle is sucked by the automatic suction device of the wire drawing machine according to the above ratio, and stirred; the raw material after stirring is melted and extruded through the wire drawing machine to form a film, and its melting temperature is 240 ° C, and its pressure At 8.5Kg; the above-mentioned film is cooled by a water tank, and the temperature of the cooling water is 50°C; the cooled film is divided by a knife row to form a monofilament; the monofilament is stretched through an oven and a traction roller, and the temper...

Embodiment 3

[0058] A kind of durable antistatic explosion-proof packaging bag of the present invention, it comprises the component composition of following percentage,

[0059]

[0060]

[0061] The antistatic functional masterbatch includes the following percentage components,

[0062]

[0063] A preparation method of durable antistatic explosion-proof packaging bag, it comprises the following steps,

[0064] (1) Wire drawing: each raw material particle is sucked by the automatic material suction device of the wire drawing machine according to the above ratio, and stirred; the raw material after stirring is melted and extruded by the wire drawing machine to form a film, and its melting temperature is 250 ° C, and its pressure At 9Kg; the above-mentioned film is cooled by a water tank, and the temperature of the cooling water is 60°C; the cooled film is divided by a knife row to form a monofilament; the monofilament is stretched through an oven and a traction roller, and the oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com