Road prime coat oil and preparation method thereof

A permeable oil and road technology, applied in the field of road permeation oil preparation, can solve the problems of high production cost of emulsified asphalt, expensive asphalt, poor permeability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

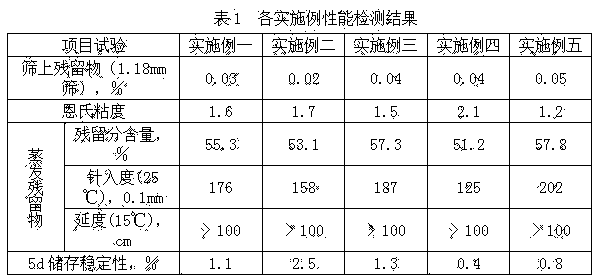

Examples

Embodiment 1

[0039] Catalytic oil slurry: 540 grams,

[0040] Emulsifier: 15 grams, PC-1310

[0041] Water: 445 grams, clear and transparent tap water without impurities

[0042] The catalytic oil slurry is firstly oxidized into shallow oxidized oil slurry through an oxidation kettle. The process conditions of shallow oxidation are: oxidation temperature 180°C, air volume 8L / min·kg, oxidation time 5h. The penetration of the oxidized oil slurry is 185 1 / 10mm , keep the lightly oxidized oil slurry at a temperature of 130°C for use. Add the emulsifier into the water and stir evenly to form a soap solution and heat it to 60°C for use. Add the hot soap liquid into the emulsification equipment and circulate it, then add the ready-to-use shallow oxidized oil slurry, and circulate and shear for 3 minutes to obtain the road penetrating layer oil product.

Embodiment 2

[0044] Catalytic oil slurry: 520 grams,

[0045]Emulsifier: 10g, FS-C01

[0046] Water: 470 grams, clear and transparent tap water without impurities

[0047] The catalytic oil slurry is firstly oxidized into shallow oxidized oil slurry through an oxidation kettle. The process conditions of shallow oxidation are: oxidation temperature 200°C, air volume 10L / min·kg, oxidation time 6h. The penetration of the oxidized oil slurry is 166 1 / 10mm , keep the lightly oxidized oil slurry at a temperature of 135°C for use. Add the emulsifier into the water and stir evenly to form a soap solution and heat it to 60°C for use. Add the hot soap liquid into the emulsification equipment and circulate it, then add the ready-to-use shallow oxidized oil slurry, and circulate and shear for 3 minutes to obtain the road penetrating layer oil product.

Embodiment 3

[0049] Catalytic oil slurry: 560 grams,

[0050] Emulsifier: 18g, JY-R4

[0051] Water: 422 grams, clear and transparent tap water without impurities

[0052] The catalytic oil slurry is firstly oxidized into shallow oxidized oil slurry through an oxidation kettle. The process conditions of shallow oxidation are: oxidation temperature 200°C, air volume 8L / min·kg, oxidation time 4h. The penetration of the oxidized oil slurry is 197 1 / 10mm , keep the lightly oxidized oil slurry at a temperature of 130°C for use. Add the emulsifier into the water and stir evenly to form a soap solution and heat it to 65°C for use. Add the hot soap liquid into the emulsification equipment and circulate it, then add the ready-to-use shallow oxidized oil slurry, and circulate and shear for 3 minutes to obtain the road penetrating layer oil product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Penetration | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com