Vertical tar tube anti-jacking slip

A technology for preventing top sticking and tubing, which is applied to drill pipes, casings, drilling equipment, etc., and can solve the problems of low degree of automation, inability to pass special tools in the internal space, and insufficient force to loosen the tubing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

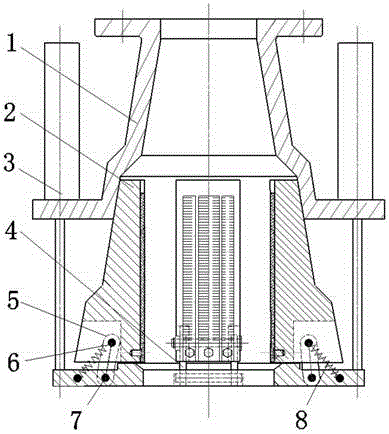

[0010] A vertical oil pipe anti-top slip is mainly used as a oil pipe hydraulic clamping tool for preventing the oil pipe from running up when the oil pipe is pulled out under pressure. It consists of a vertical slip seat (1), a slip body ( 2), liquid cylinder (3), support disc (4), connecting rod sheet (5), upper pin shaft (6), lower pin shaft (7), extension spring (8) etc. composition. The slip seat (1) is a disc-type overall structure. The slip body (2) and the slip seat (1) are in contact with the same size circular arc cone surface and can slide up and down relatively. The bottom of the cone surface is large and the top is small. (3) Fixed on the slip seat (1) and remotely controlled up and down movement through the hydraulic switch valve, the piston rod of the hydraulic cylinder (3) is fixed on the support plate (4), and the lower pin shaft (7) is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com