Method for simulating and testing assembling pressures on AGM (absorptive glass met) separators for start-stop batteries

A technology for simulating testing and assembly pressure, applied in the direction of measuring force, measuring devices, instruments, etc., can solve problems such as cyclic discharge attenuation, insufficient resilience, and drop in extreme group pressure, and achieve the effect of improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

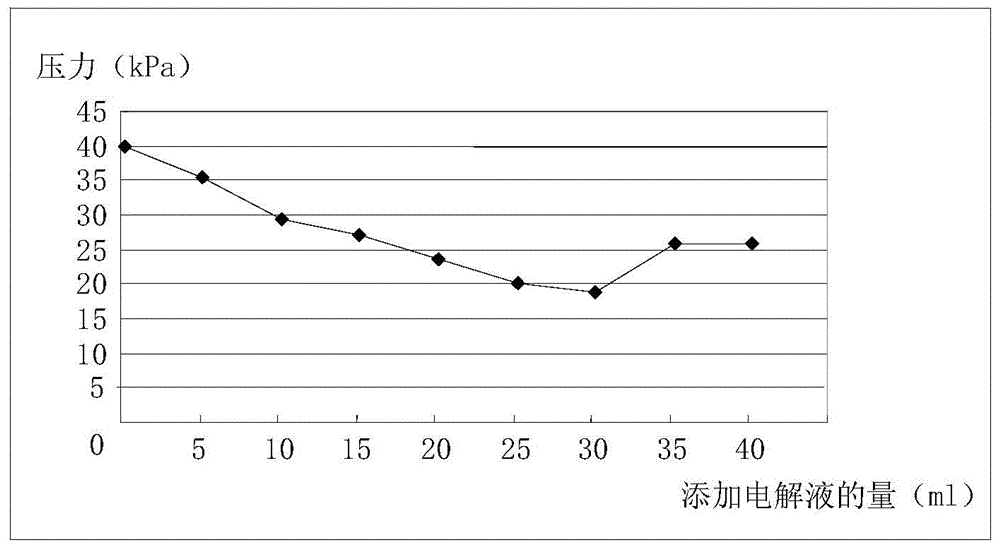

[0026] The test method for the assembly pressure of the AGM separator for the start-stop battery of the present embodiment comprises the following steps:

[0027] (1) Cut the partition into 100×100mm, take three pieces and stack them together, wrap them in plastic bags, and reserve the liquid filling port in the plastic bags;

[0028] (2) Clamp the partition with a clamp and apply a pre-tightening force of 400N;

[0029] (3) Stand still for 1 to 2 minutes, adjust the pressure of the fixture to the initial pre-tightening force, and repeat several times until the pressure of the fixture is stable;

[0030] (4) Intermittently add electrolyte to the liquid filling port, the time interval between two adjacent additions of electrolyte is 3min, the amount of electrolyte added each time is 5mL, and the pressure of the clamp clamping the diaphragm is measured before each water addition;

[0031] (5) If the separator seeps out of the electrolyte, it means that the separator absorbs the...

Embodiment 2

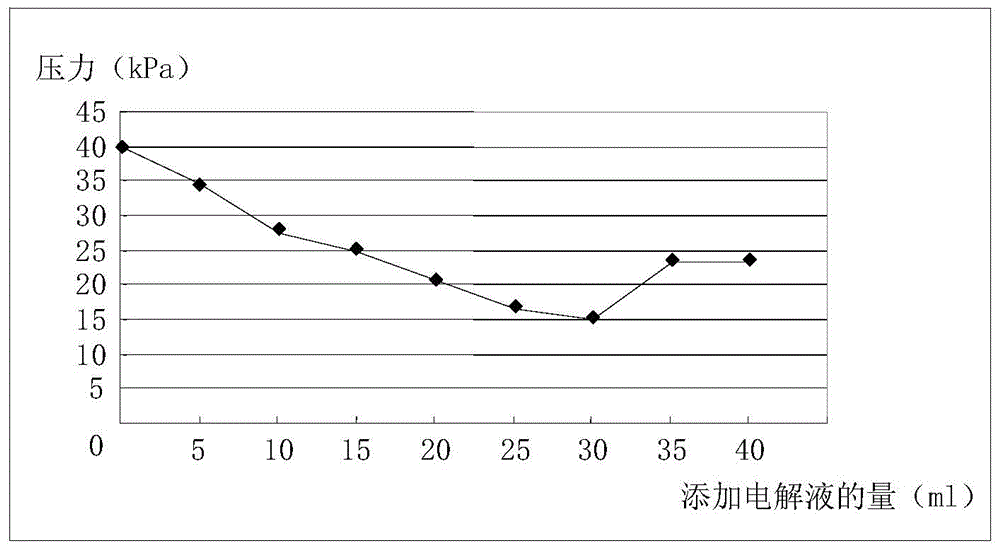

[0034] In this embodiment, except that the material of the separator is different from that of Embodiment 1, other operations are the same.

[0035] Select two groups of separator samples 2 of the same specification, and one group carries out the test method of this embodiment, and the test results are as follows: figure 2 As shown, the pre-tightening force on the separator is 40kPa, the minimum pressure is 15.2kPa, and the pressure remains at 22.2kPa after rebounding; another set is manufactured and assembled with two start-stop batteries with the same pre-tightening force. After the manufacturing is completed, use the pressure sensor to test The assembly pressures of the inner separators of the two start-stop batteries are 22.0kPa and 22.1kPa respectively.

Embodiment 3

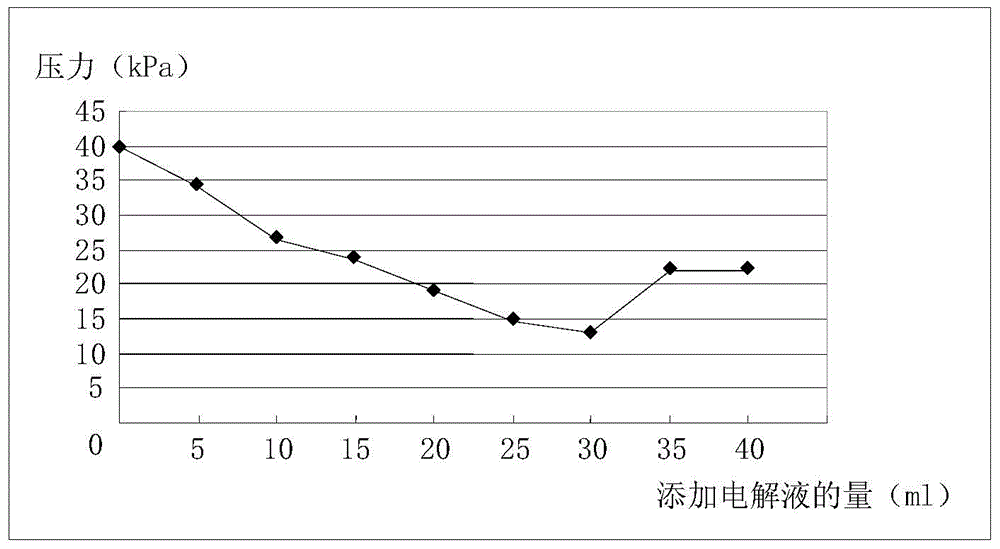

[0037] In this embodiment, except that the material of the separator is different from that of Embodiment 1 and Embodiment 2, other operations are the same.

[0038] Select two groups of separator samples of the same specification three, one group to carry out the test method of this embodiment, the test results are as follows figure 2 As shown, the pre-tightening force on the separator is 40kPa, the minimum pressure is 13.7kPa, and the pressure remains at 21.5kPa after rebounding; the other set is manufactured with the same pre-tightening force and assembled with two start-stop batteries. After the manufacturing is completed, use the pressure sensor to test The assembly pressures of the inner separators of the two start-stop batteries are 21.2kPa and 21.4kPa respectively.

[0039] It can be seen from the above examples that the test method for the assembly pressure of the AGM separator for the start-stop battery of the present invention can accurately and efficiently test th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com