Magnifying lens device used for lamp detector and detection method

A magnifying glass and light inspection technology, which is applied to magnifying glasses, measuring devices, and optical testing flaws/defects, etc., can solve problems such as increased uncertainty, inaccurate identification, and increased production costs, so as to reduce the probability of identification errors and facilitate operation and training, reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

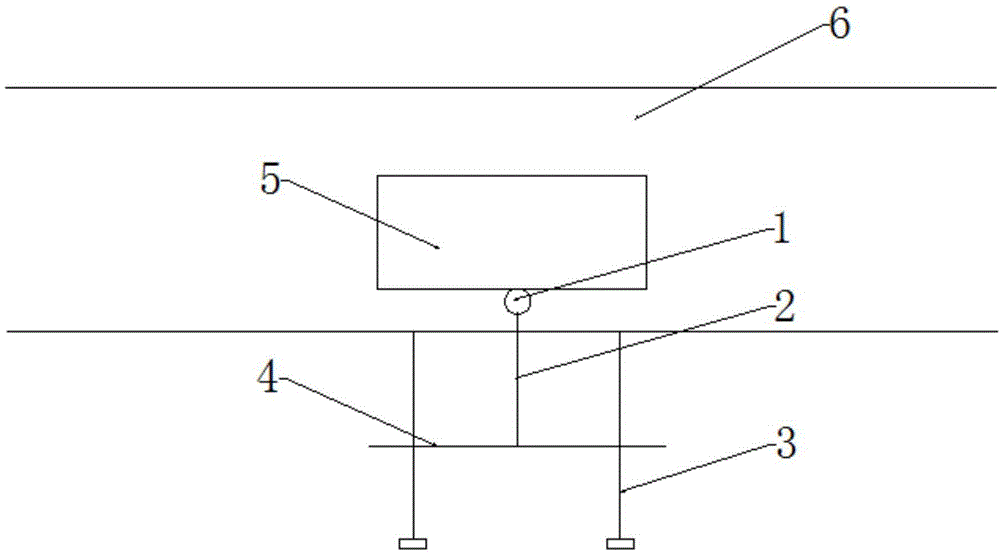

[0024] Such as figure 1 As shown, a magnifying glass device for light inspection includes a rotating shaft 1, a height adjuster 2, a magnifying glass 5, a front and rear propulsion instrument 3, and a fixed bracket 4. Installed on the front and rear propulsion instrument 3, the fixed bracket 4 is parallel to the conveyor belt, and the telescopic height adjuster 2 is arranged perpendicular to the conveyor belt. One end of the height adjuster 2 is connected to the middle of the fixed bracket 4, and the other end is movably connected to the rotating shaft 1, and the magnifying glass 5 is fixed on the rotating shaft 1.

[0025] The magnifying glass 5 is connected to the height adjuster 2 through the rotating shaft 1, and one end of the height adjusting device 2 is connected on the fixed bracket 4, the angle of the magnifying glass 5 can be changed through the rotating shaft 1, and the height position of the magnifying glass 5 is adjusted through the height adjuster 2, which is con...

Embodiment 2

[0027] A method for improving inspection efficiency during lamp inspection, using the magnifying glass device used for lamp inspection in Embodiment 1 to perform lamp inspection.

[0028] The method comprises the steps of:

[0029] (1) Adjust the height position of the magnifying glass through the height regulator;

[0030] (2) Use the forward and backward thruster to adjust the focal length between the magnifying glass and the test product;

[0031] (3) Rotate the rotating shaft to adjust the angle between the magnifying glass and the detection product;

[0032] (4) Observing impurities and suspended solids in the bottle illuminated by the backlight through a magnifying glass for detection.

Embodiment 3

[0034] Select skilled workers for the light inspection post and divide them into two groups on average, namely the experimental group (using the light inspection equipment and method) and the control group (not using the light inspection equipment and method).

[0035] Effect comparison: the number of unqualified products picked out by the test group is 90% less than that of the control group. Among the unqualified products picked out, the number of qualified products such as trachoma picked out by the test group is far less than that of the control group, and the test group is 2 shifts in half a working day, less than 3 shifts in half a working day of the control group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com