Motor control method

A technology for motor control and control instructions, applied in computer control, program control, general control systems, etc., can solve the problem of increased procurement costs, and achieve the effect of reducing procurement costs, simplifying installation, and reducing the number and types of interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

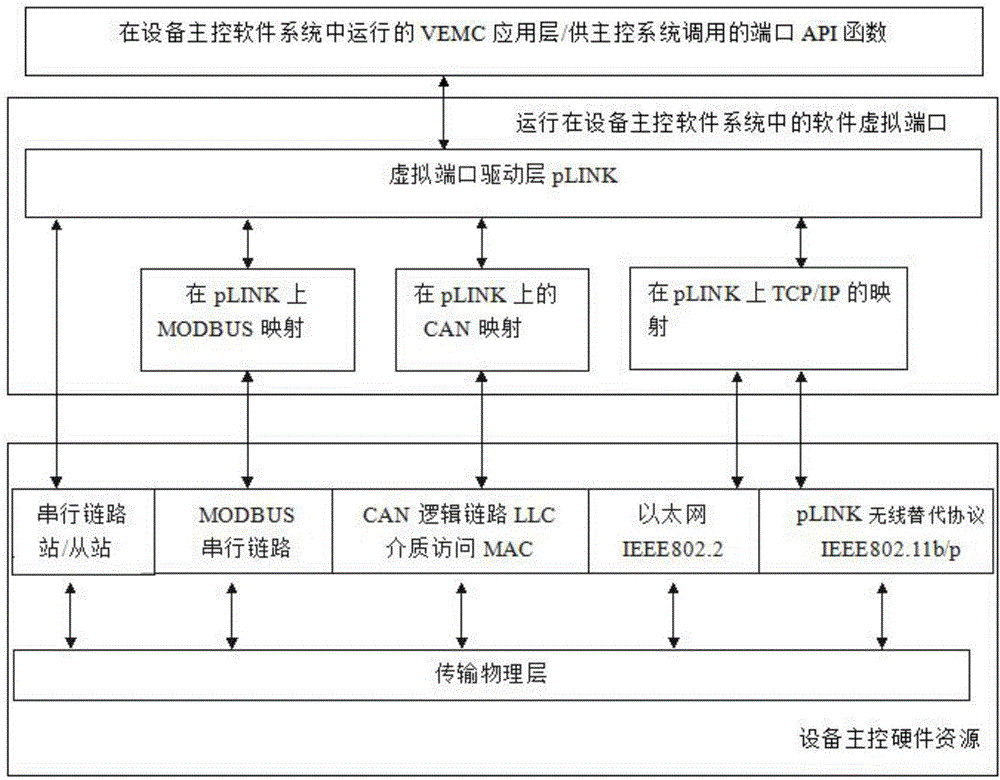

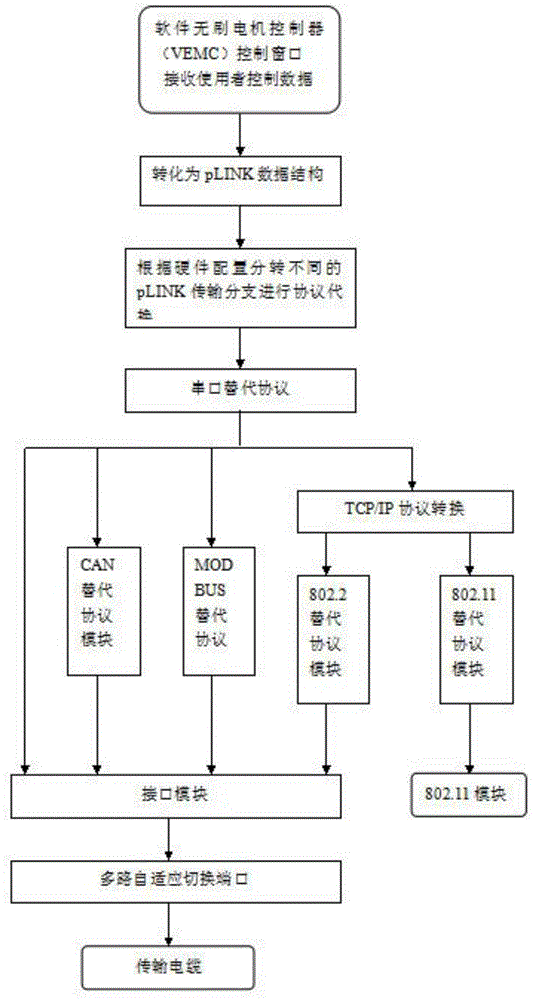

[0044] Embodiment 1: as figure 1 As shown, a brushless motor control method is mainly to copy the port in the form of pure digital through pLINK, and map out the virtual port with the same function as the physical control port, so as to realize the separation of the control port from the brushless motor controller body , away from the harsh working environment full of various oils, water, dust, and metal debris, so as to simplify equipment installation, maintenance and interface protection, and reduce costs. Such as image 3 As shown, the specific steps are as follows:

[0045] Step 1: Perform virtual port initialization configuration in the microprocessor. The microprocessor is a local microprocessor and a remote microprocessor, and the virtual port is a local virtual port and a remote virtual port. The local virtual port completes the initial configuration in the local microprocessor, and the remote virtual port completes the initial configuration in the remote microproces...

Embodiment 2

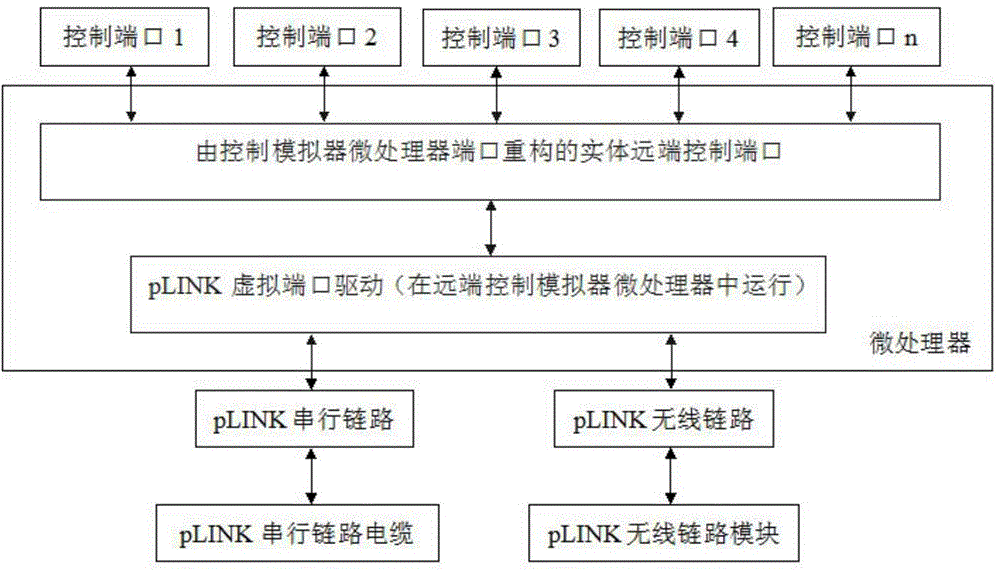

[0059] Embodiment 2: as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment restores the control port of the entity at the remote control end for manual control, which is suitable for one-to-one or one-to-two remote control. Its composition is as follows: the microprocessor in the virtual port emulator leads to the control port of the entity, and the input is a pLINK cable or a wireless network module. Since the remote physical port can be far away from the brushless motor controller, it can be placed in a place that does not require high-level protection, and ordinary non-three-proof connectors can be used.

[0060] The virtual port driver running in the microprocessor replaces the physical control port and duplicates the virtual control port in the microprocessor memory. At the same time, the driver program running in the microprocessor establishes the mapping relationship with the virtual port through the controller port cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com