Constant temperature ironing and fixed length cutting control system

A control system, constant temperature technology, applied in general control systems, control/regulation systems, temperature control by electric means, etc., can solve the problems of large shrinkage and deformation of chemical fiber fabrics, no fixed-length cutting, quality impact, etc. Technological innovation and advancement, ensuring consistency and excellence, and improving the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

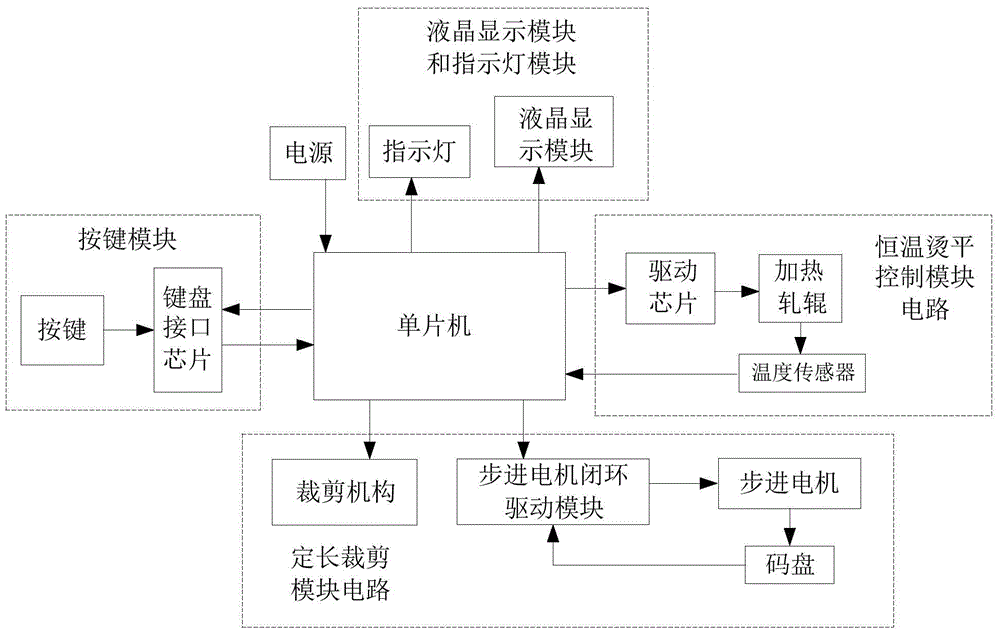

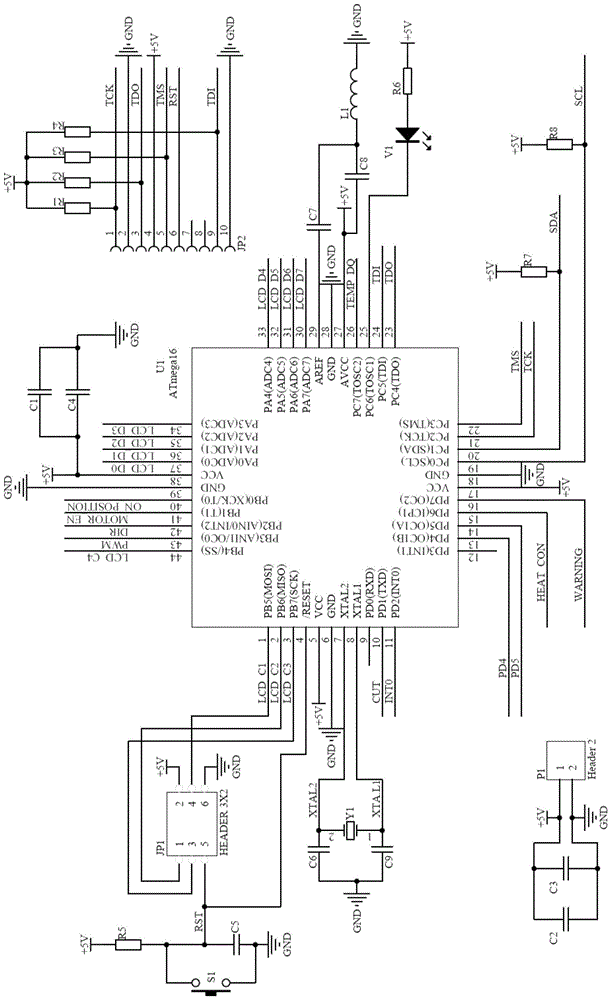

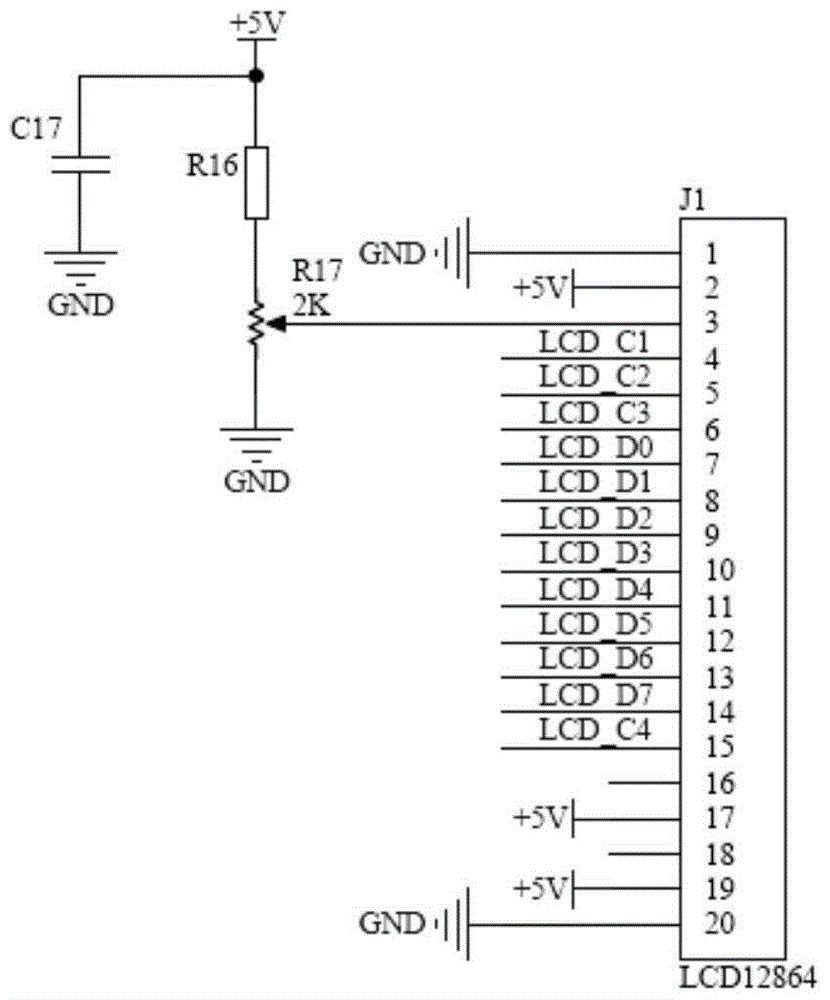

[0025] Such as figure 1As shown, the present invention includes a single-chip microcomputer module circuit, a liquid crystal display module circuit, an indicator light module circuit, a constant temperature ironing control module circuit, a button module circuit and a fixed-length cutting module circuit; the power input is connected to the single-chip microcomputer module circuit, and the single-chip microcomputer module circuit It is connected with the liquid crystal display module circuit, the indicator light module circuit, the constant temperature ironing control module circuit, the button module circuit and the fixed-length cutting module circuit.

[0026] The whole system adopts single-chip microcomputer as the control core, and the system input is mainly input by keys. The fixed-length cutting module includes a stepper motor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com