Indexable rotating tool

A technology of rotating tools and indexing, used in manufacturing tools, thread cutting tools, workpieces, etc., can solve the problem of not being able to be fixed in one piece, and achieve the effect of superior cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

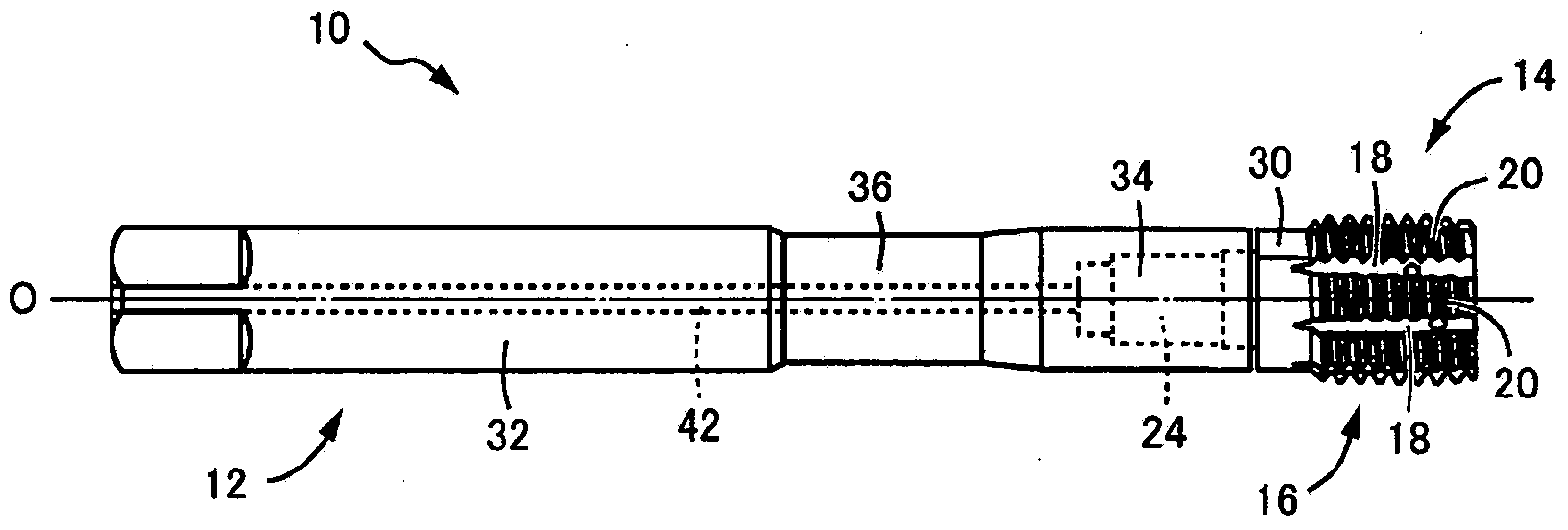

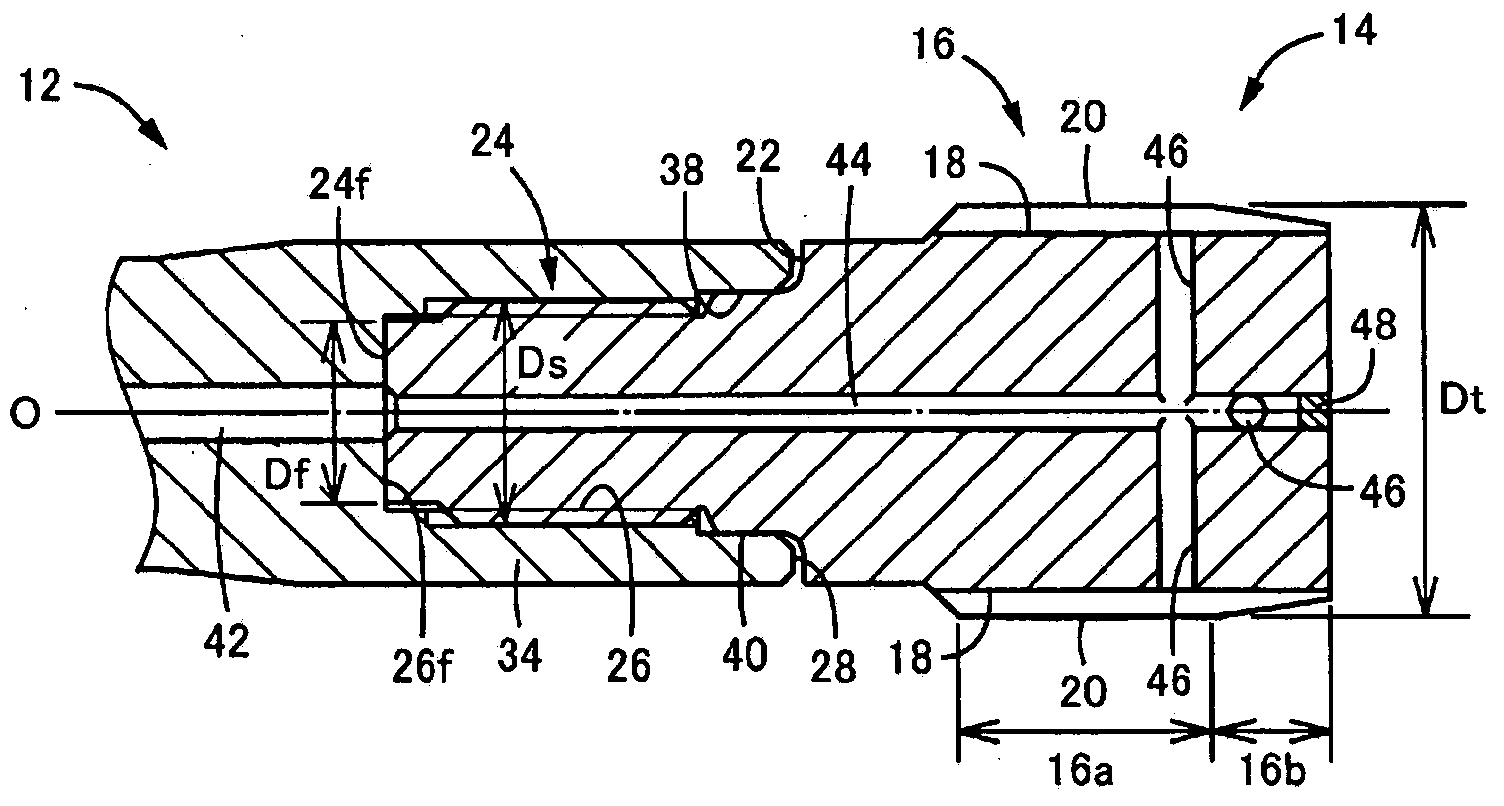

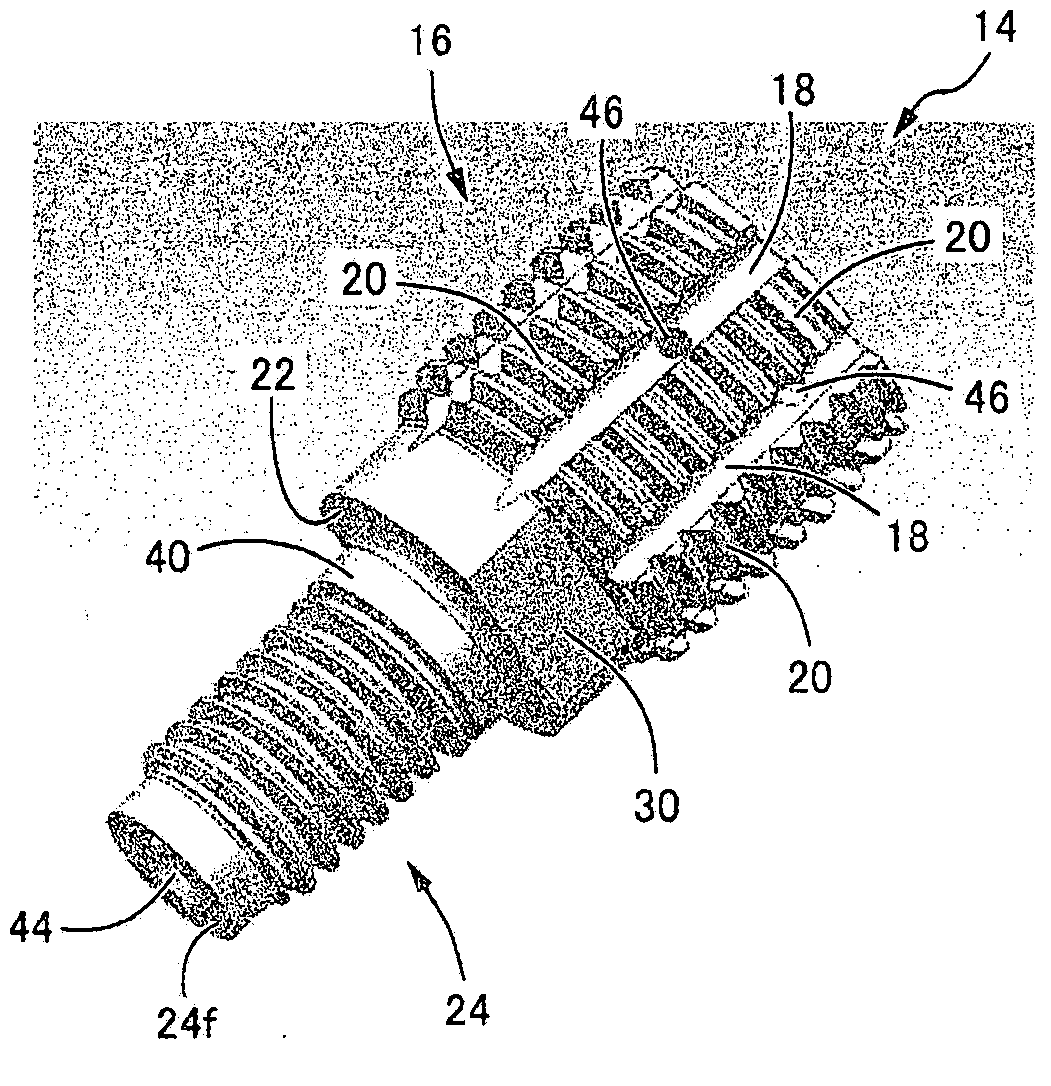

[0052] figure 1 It is a diagram showing an indexable extrusion tap (hereinafter referred to as an extrusion tap) 10 as an embodiment of the present invention, and is a front view viewed from a direction at right angles to the axis O. figure 2 Is an enlarged cross-sectional view of the tip portion of the extrusion tap 10 including the cutting blade 14, image 3 It is a perspective view showing the cutting insert 14 separately. This extrusion tap 10 includes a shaft-shaped main body 12 and a cutting blade 14 concentrically detachably mounted on the front end of the main body 12 by screwing. The cutting blade 14 performs thread rolling by rotating and driving about the axis O. Press processing. The main body 12 is made of die steel or high-speed tool steel. On the other hand, the cutting insert 14 is made of cemented carbide. The surface of the cutting blade 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com