Ship drag reducing device, manufacturing unit and manufacturing method for manufacturing the drag reducing device

A drag reduction device and manufacturing unit technology, applied in ship construction, ship parts, hull design, etc., can solve problems such as lack of realism, weak welding heat of composite materials, difficulty in ship drag reduction devices, etc., to improve proximity, reduce The effect of fuel consumption and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

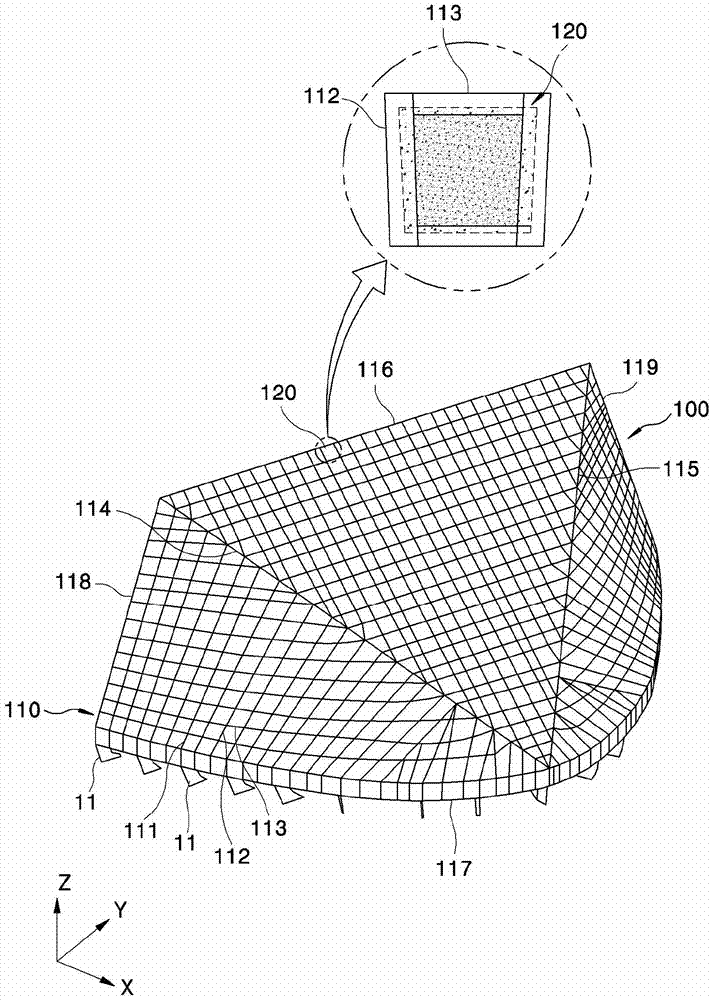

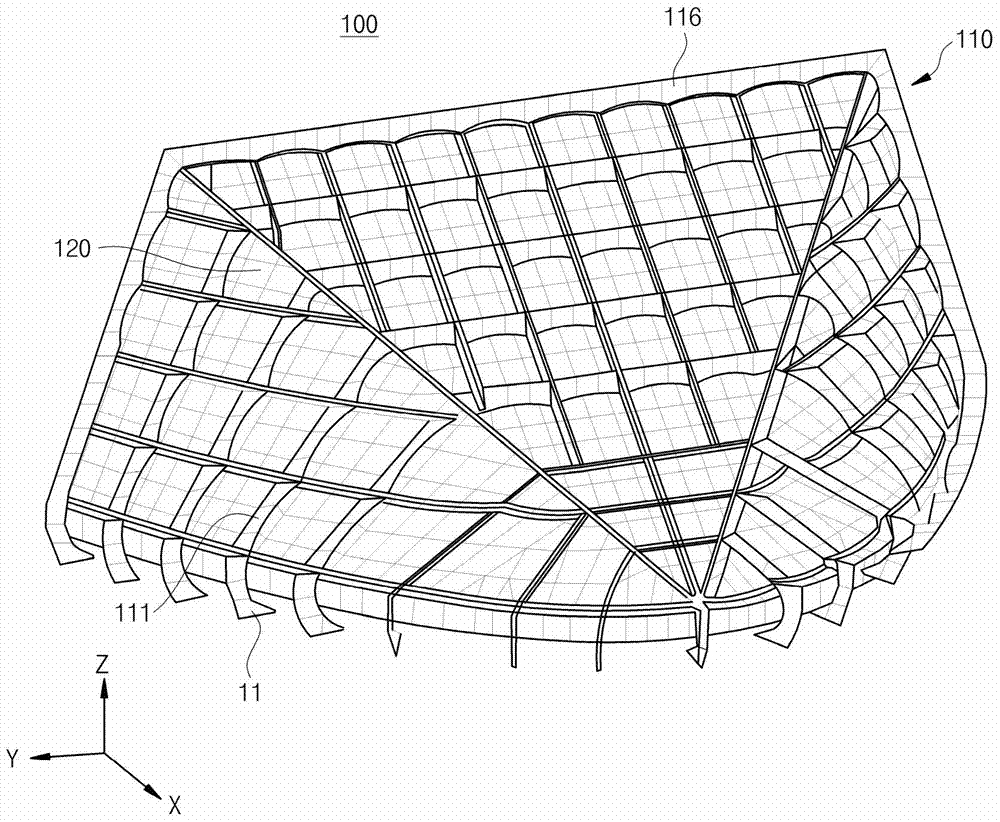

[0064] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

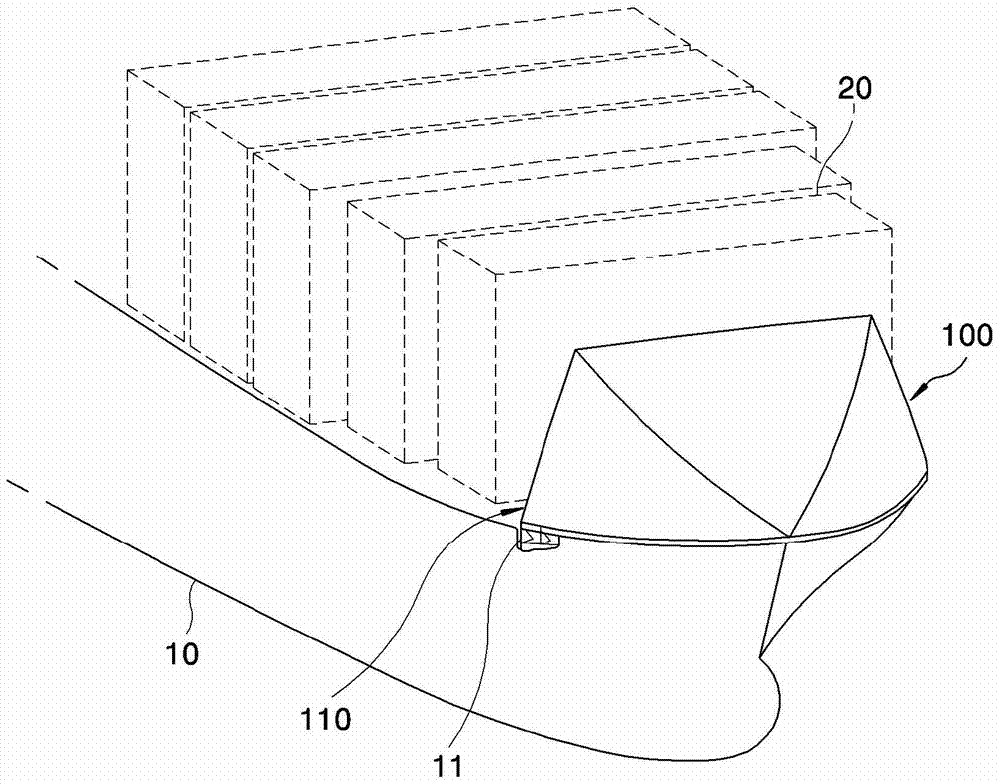

[0065] figure 1 It is a use state diagram which shows the state in which the drag reducing device of the ship of the embodiment of this invention is applied to a ship.

[0066] refer to figure 1 , the drag reducing device 100 of the embodiment of the present invention can be installed on the bow side deck of the ship 10 . For example, the ship 10 may include an ultra-large container ship, but is not limited thereto. When the ship 10 is sailing, the drag reducing device 100 can block or reduce the resistance caused by air, water (for example, ship deck waves), and wind to the ship body, thereby reducing the fuel consumption of the ship 10 . In addition, the drag reducing device 100 can also prevent the maximum speed of the ship 10 from decreasing or improve the efficiency of the maneuverability of the ship 10 .

[0067] The drag reducing device 100 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com