Tiller for tea garden

A technology for cultivating machines and tea gardens, applied in the field of agricultural machinery, can solve the problems of being unsuitable, difficult to reach more than 25 centimeters, only reaching twelve or three centimeters, etc., and achieve the effects of stable transmission, simple structure and compact mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

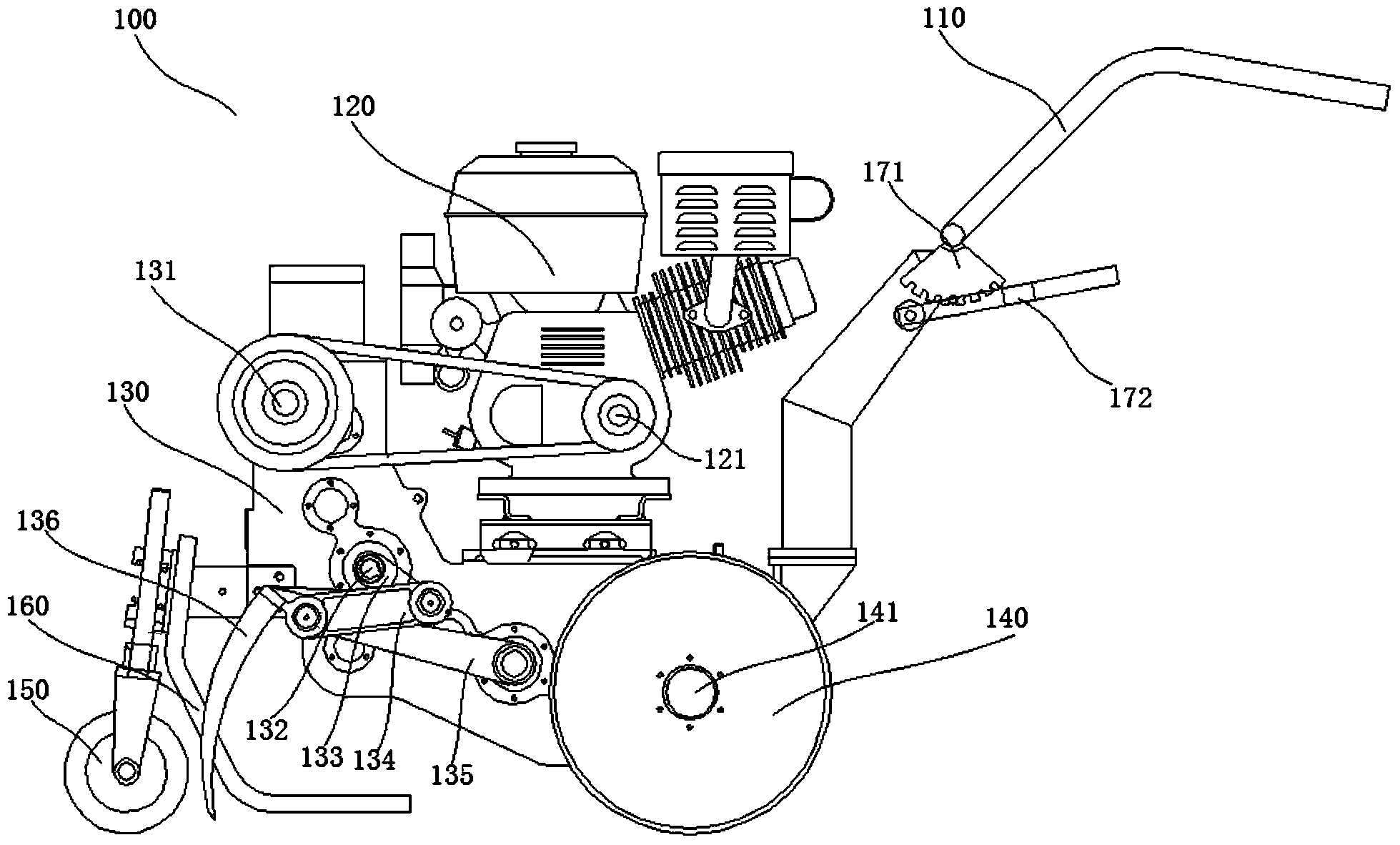

[0028] Such as figure 1 As shown, the tea garden cultivator provided in this implementation has a handle 110, a power mechanism 120, a gear box 130, a driving wheel 140 and a guide wheel 150 on the mechanical body 100, and the handle 110 is located at the rear end of the mechanical body 100 for supporting , the driving wheel 140 is located at the lower part of the machine body 100 for providing driving power, and the guide wheel 150 is used for guiding the machine body 100 when walking.

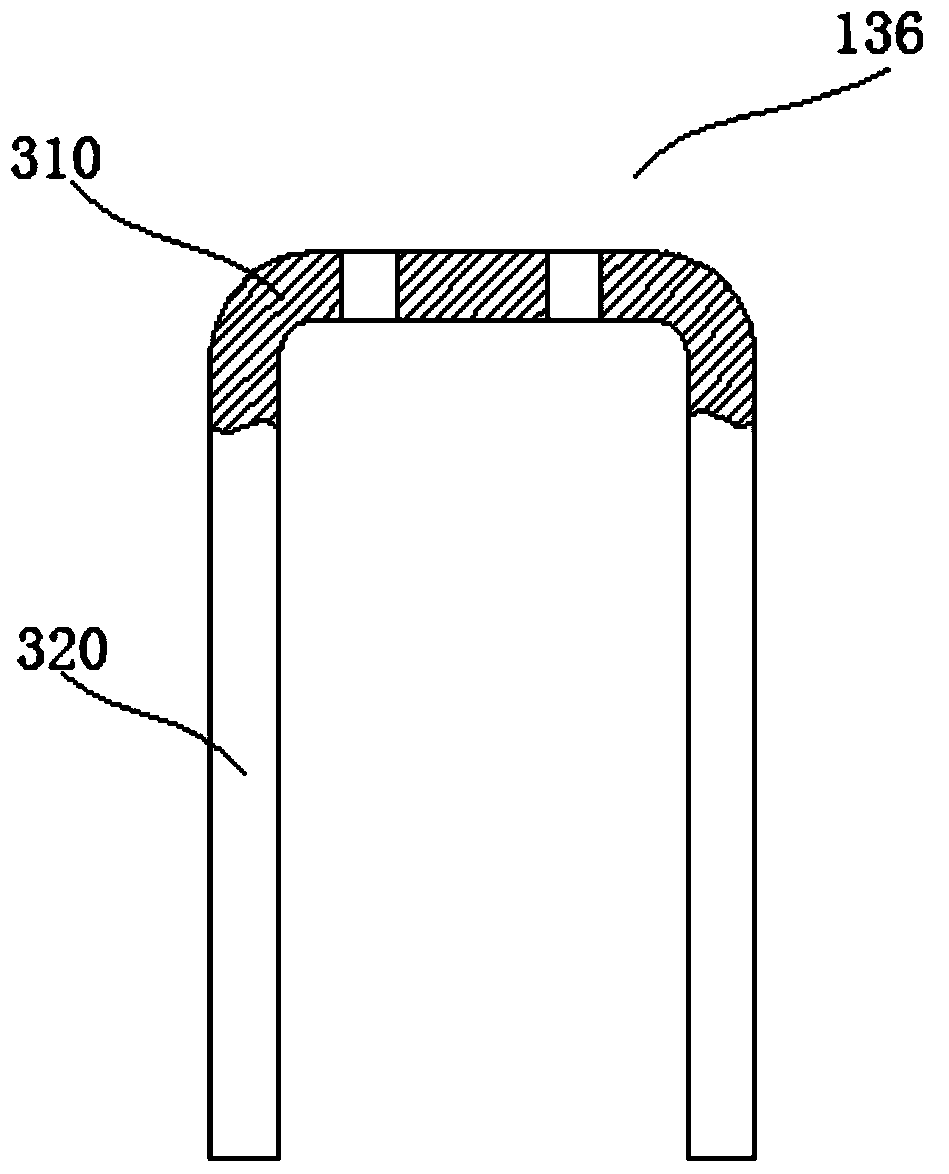

[0029] Gear box 130 is provided with driving arm 133, tilling arm 134 and connecting rod 135, and power mechanism 120 transmits power to driving arm 133 and driving wheel 140 by gear box 130; Driving arm 133, tilling arm 134 and connecting rod 135 are constructed as crank As for the link mechanism, the tilling arm 134 is provided with tilling teeth 136 for planing soil.

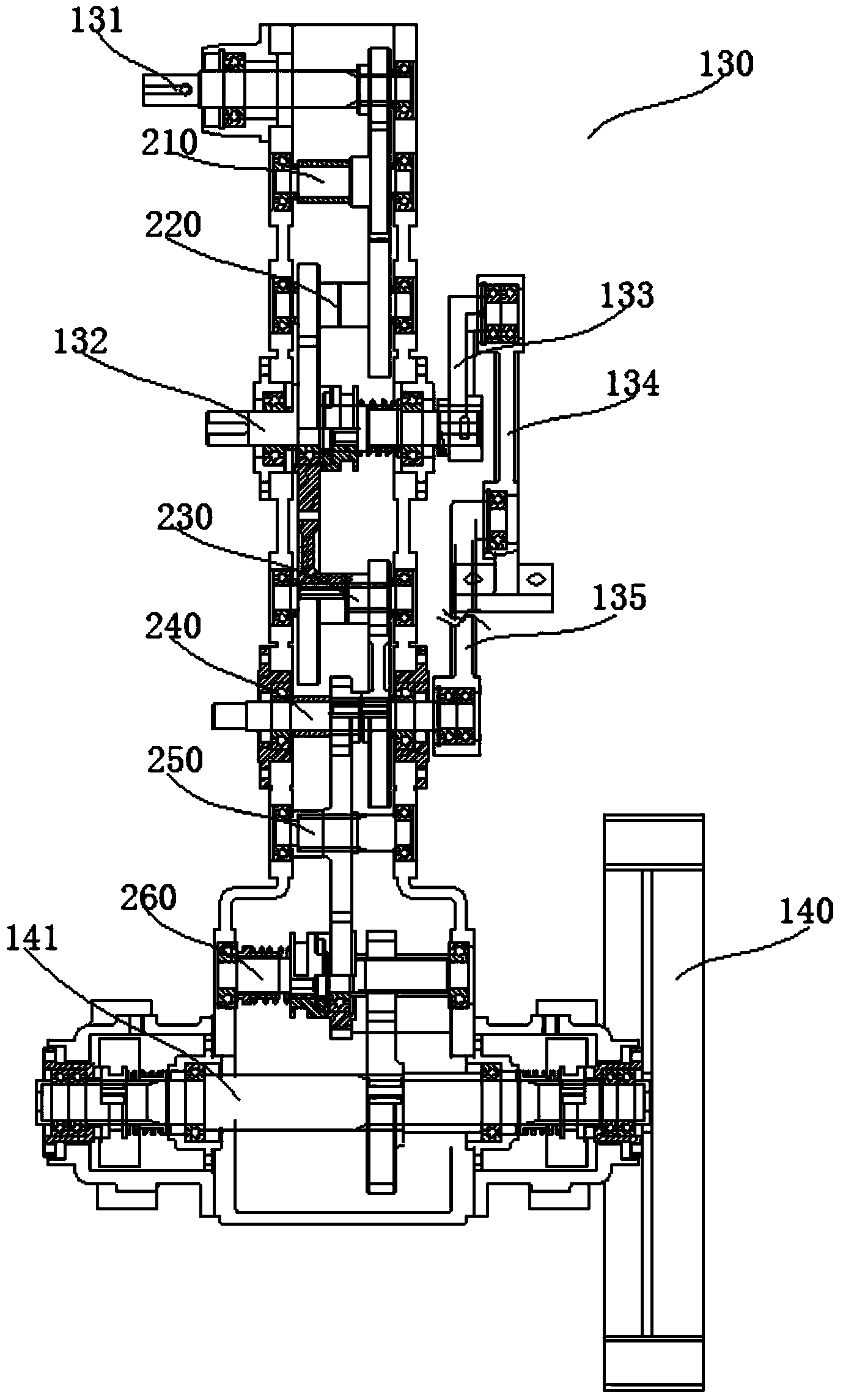

[0030] Such as figure 2 As shown, it is used for the gear box of tea garden cultivator in this implementation, is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com