Underground rapid wind coal gangue separation device

A technology of coal gangue separation and wind power, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problem of high efficiency of buoyancy separation of coal gangue, the speed of the conveyor belt should not be too large, and the equipment volume Large and other problems, to achieve the effect of saving transportation volume, reducing transportation costs, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

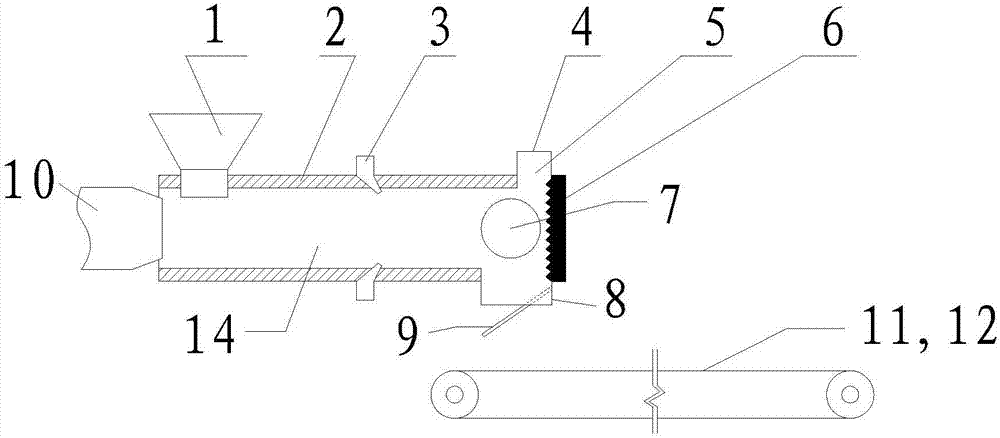

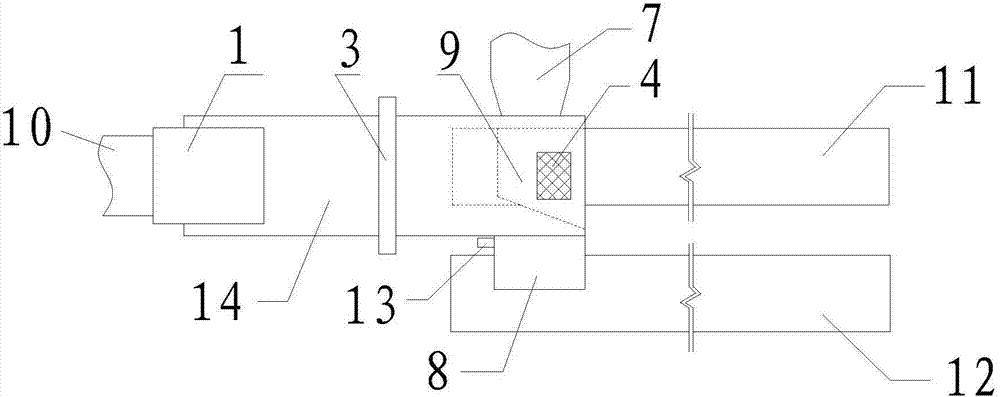

[0014] The underground rapid wind coal gangue separation device of the present invention is mainly composed of a wind acceleration tube 14 and a gangue transport belt 11 and a coal transport belt 12 arranged below it. The two ends of the wind acceleration tube 14 are respectively arranged with the main high-pressure blowing outlet 10 and the washboard type impact plate 6, and the discharge port 1 and the air return port 5 are respectively arranged at the upper two ends of the wind force acceleration tube 14; at the impact plate end of the wind force acceleration tube 14 , the two sides of the end are respectively arranged with auxiliary high-pressure blowing outlet 7 and coal outlet 8, and the bottom of wind acceleration tube 14 is arranged with gangue outlet 9; right below coal outlet 8 and gangue outlet 9 are correspondingly arranged coal conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com