Multilayer tray feeding mechanism

A feeding mechanism and tray technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low efficiency, simple structure, busy workers, etc., and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

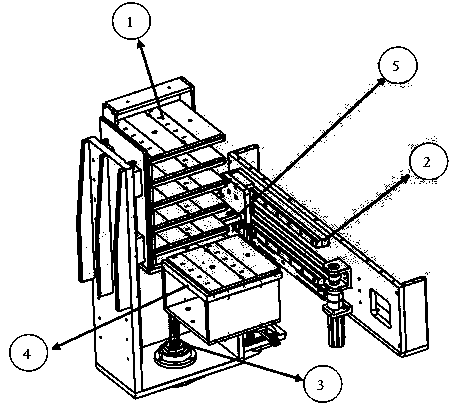

[0014] The multi-layer tray feeding mechanism includes a multi-layer storage tray 1, a tray handling mechanism 2, a tray lifting shaft 3, a tray temporary storage platform 4, and a tray lifting mechanism 5. It is characterized in that the multi-layer storage tray Tray 1 can accommodate multi-layer material trays, and multi-layer material storage tray 1 moves up and down through the storage tray lifting shaft 3 on the lower layer. When the storage tray 1 is at the highest position, the position of the bottom storage tray is that the tray platform and the multi-layer storage tray 1 are arranged side by side, and a tray handling mechanism 2 is arranged on the side of the tray platform and the multi-layer storage tray 1. One end of the tray handling mechanism 2 close to the multi-layer storage tray 1 is provided with a tray lifting mechanism 5, the tray lifting mechanism 5 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com