Preparation method of 1, 3-diaminoguanidine monohydrochloride

A technology of diaminoguanidine and hydrochloride, which is applied in the fields of phosphate, phosphorus oxyacid, organic chemistry, etc., can solve the problems of high toxicity of dimethyl sulfate, long synthetic route, complicated operation, etc., and achieve the benefit of large-scale Industrialized production, improved production profit, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

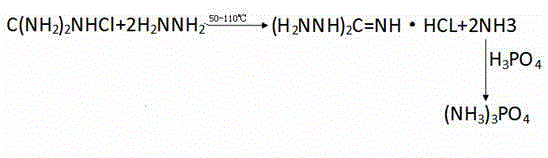

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of 1,3-diaminoguanidine hydrochloride, concrete steps are as follows:

[0025] (1) Put guanidine hydrochloride (1Kg) and water (2Kg) into the reaction kettle, stir until the guanidine hydrochloride is completely dissolved, then add 1.0Kg of toluene (the mass ratio to water is 1:0.5), and then slowly add hydrazine hydrate ( 1.02Kg, the molar ratio of guanidine hydrochloride is 1:1.9,), the rate of addition is 2.0kg / h, after the dropwise addition, react at 60°C for 10h, adjust the pH to 2.5 with hydrochloric acid, let stand to separate the liquid, take the water layer and distill and concentrate There is a trace of precipitate in the water layer, and the concentrated solution is about (1.5Kg). In the reaction, the tail gas is passed into the tail gas absorption device, and the by-product ammonia produced in the reaction is absorbed by the three-level acid solution to obtain the ammonium salt solution. The acid solution Sequentially: mass fract...

Embodiment 2

[0028] A kind of preparation method of 1,3-diaminoguanidine hydrochloride, concrete steps are as follows:

[0029] (1) Put guanidine hydrochloride (10Kg) and aqueous solution (20Kg) into the reaction kettle, stir until the guanidine hydrochloride is completely dissolved, then add toluene (4Kg, the mass ratio to water is 1:0.2), and then slowly add hydrazine hydrate ( 10.4Kg, the molar ratio to guanidine hydrochloride is 1:2), the dropping rate is 2.5kg / h, after the dropwise addition, react at 70°C for 9h, adjust the pH to 2.5 with hydrochloric acid, let stand to separate the liquid, take the water layer and distill and concentrate to There is a small amount of precipitate in the water layer, and the concentrated solution is obtained about (15.1Kg). The by-product ammonia produced in the reaction absorbs the ammonium salt solution with a tertiary acid solution, and the acid solution is successively: mass fraction 85% phosphoric acid aqueous solution, mass fraction 50% phosphori...

Embodiment 3

[0032] A kind of preparation method of 1,3-diaminoguanidine hydrochloride, concrete steps are as follows:

[0033] (1) Put guanidine hydrochloride (1Kg) and water (4Kg) into the reaction kettle, stir until the guanidine hydrochloride is completely dissolved, then add toluene (1.6Kg, the mass ratio to water is 1:0.4), and then slowly add hydrazine hydrate dropwise (1.05Kg, molar ratio to guanidine hydrochloride 1:2.0), the dropping rate is 2.25kg / h, after the dropwise addition, react at 60°C for 10h, adjust the pH to 2.5 with hydrochloric acid, let stand to separate the liquid, take the water layer and distill and concentrate There is a trace of precipitate in the water layer, and about (2.5Kg) of the concentrated solution is obtained. In the reaction, the tail gas is passed into the tail gas absorbing device, and the by-product ammonia produced in the reaction is absorbed with a three-stage acid solution to obtain an ammonium salt solution. The acid solution Sequentially: mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com