A method of spraying anti-sticking agent for vinyl chloride polymerization kettle

A technology of vinyl chloride polymerization and anti-sticking agent, which can be applied to devices and coatings for coating liquid on the surface, which can solve the problems of difficulty in adhesion and waste of anti-sticking agent, improve spraying efficiency and reduce sticking objects. , the effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

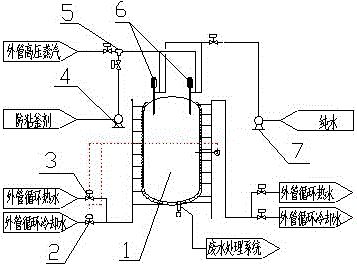

[0021] Refer to attached figure 1 Among them, a method for spraying anti-sticking agent in a vinyl chloride polymerization kettle according to the present invention includes an anti-sticking agent feeding system, a steam injection system, a high-pressure spray system, a heating / cooling system, and anti-sticking in a vinyl chloride polymerization kettle. Before the kettle agent is sprayed, start the high-pressure spray system, the pure water is pressurized by the high-pressure water pump 7 and enters the automatic spray valve 6, and the high-pressure water is sprayed into water mist to clean the residue on the wall of the polymerization kettle 1; after the spraying is completed, start the heating / Cooling system, heat up the polymerization kettle through the hot water regulating valve 3 of the outer pipe, and then start the steam injection system and the anti-sticking kettle agent feeding system, and the anti-sticking kettle agent is delivered to the liquid suction port of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com