Hybrid wind power generator

A wind power generation device and a hybrid technology, applied in wind power generation, wind turbines, wind turbine combinations, etc., can solve the problems of restricting the promotion and popularization of wind turbines, short service life of friction generators, and poor ability to respond to accidents. Ease of high-density integration, improved service life, and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

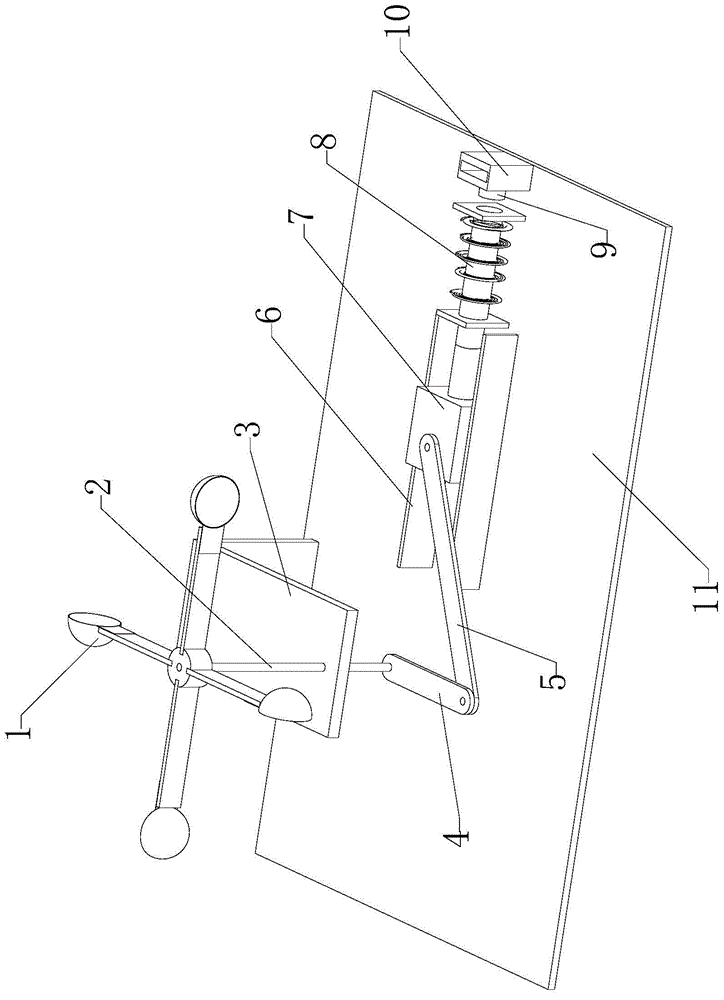

[0020] In order to better understand the purpose, structure and function of the present invention, a hybrid wind power generation device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

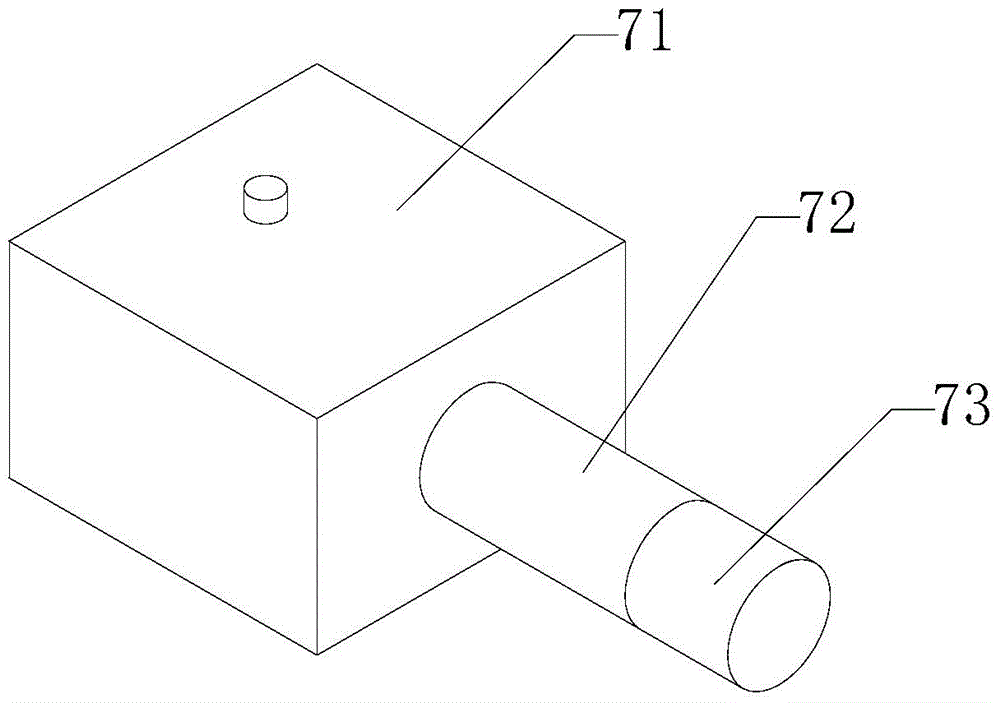

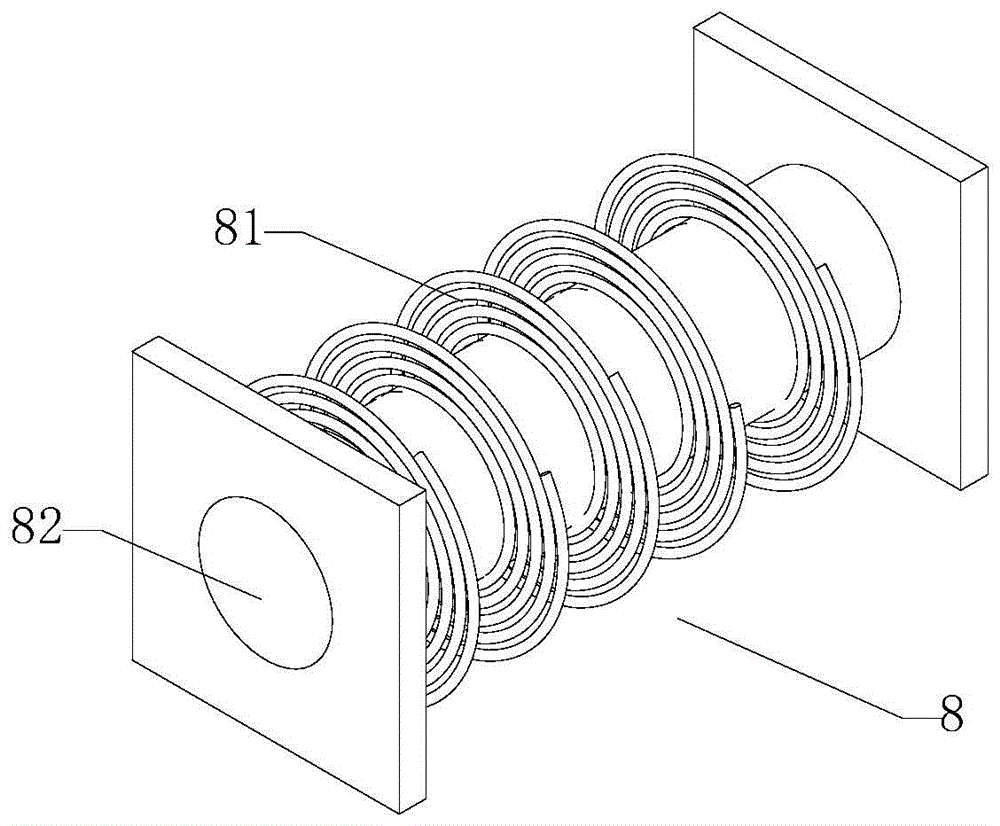

[0021] The hybrid wind power generation device of the present invention includes a wind energy receiving assembly, a crank connecting rod assembly, a sliding magnet assembly, an electromagnetic power generation assembly and a friction power generation assembly. Among them, the wind energy receiving component is used to collect wind energy in nature and convert the wind energy into mechanical energy; one end of the crank connecting rod component is connected with the wind energy receiving component, and the other end is connected with the sliding magnet component, which is used to transmit the mechanical energy generated by the wind energy receiving component Give the sliding magnet assembly to drive the sliding magnet assembly to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com