Schizothoracinae otolith slice production method

A production method and otolith technology, which is applied in the field of production of fish otolith slices, can solve the problems of complicated operation, unsuitable operation, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

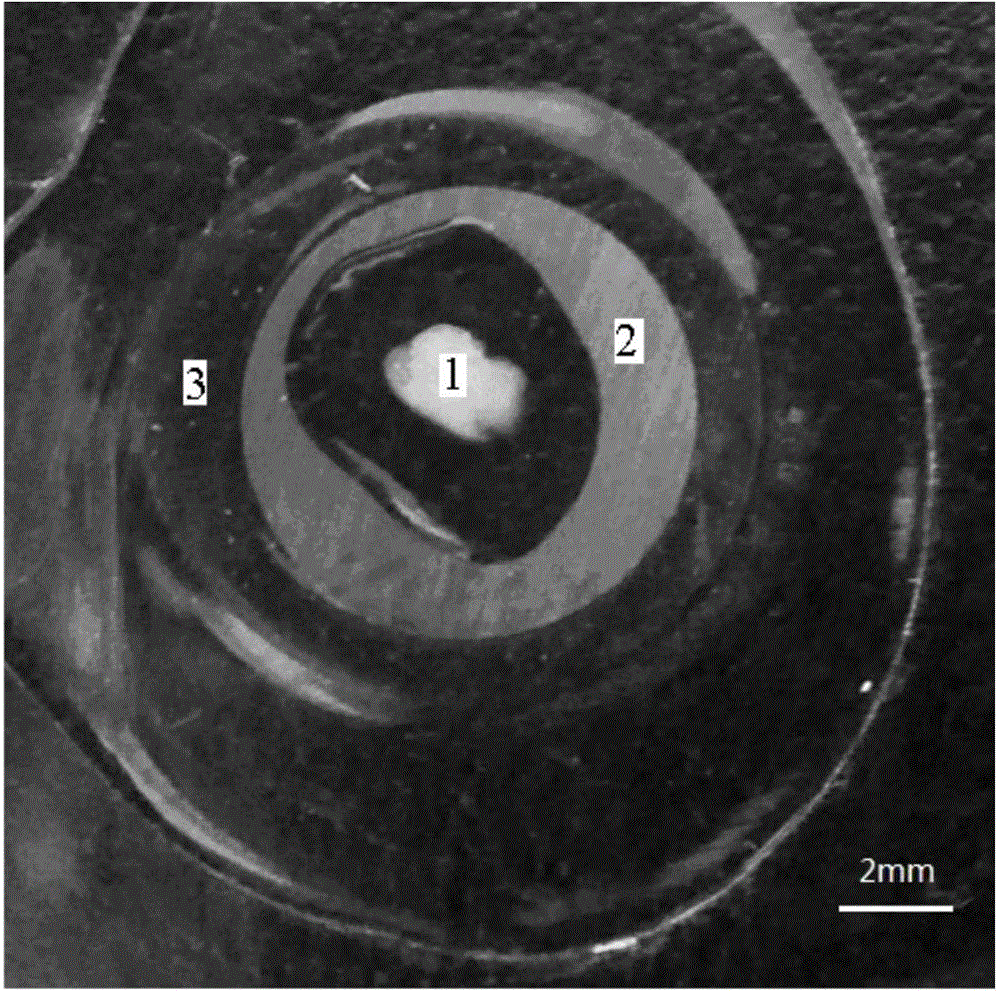

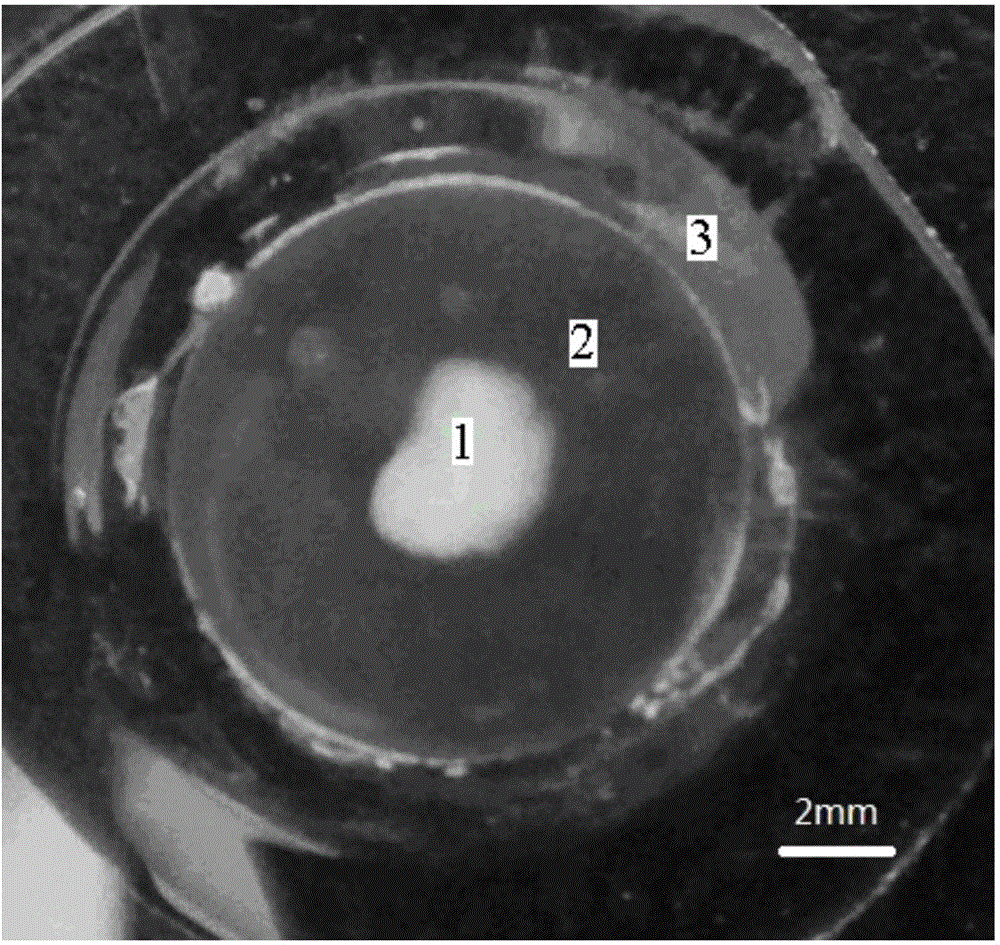

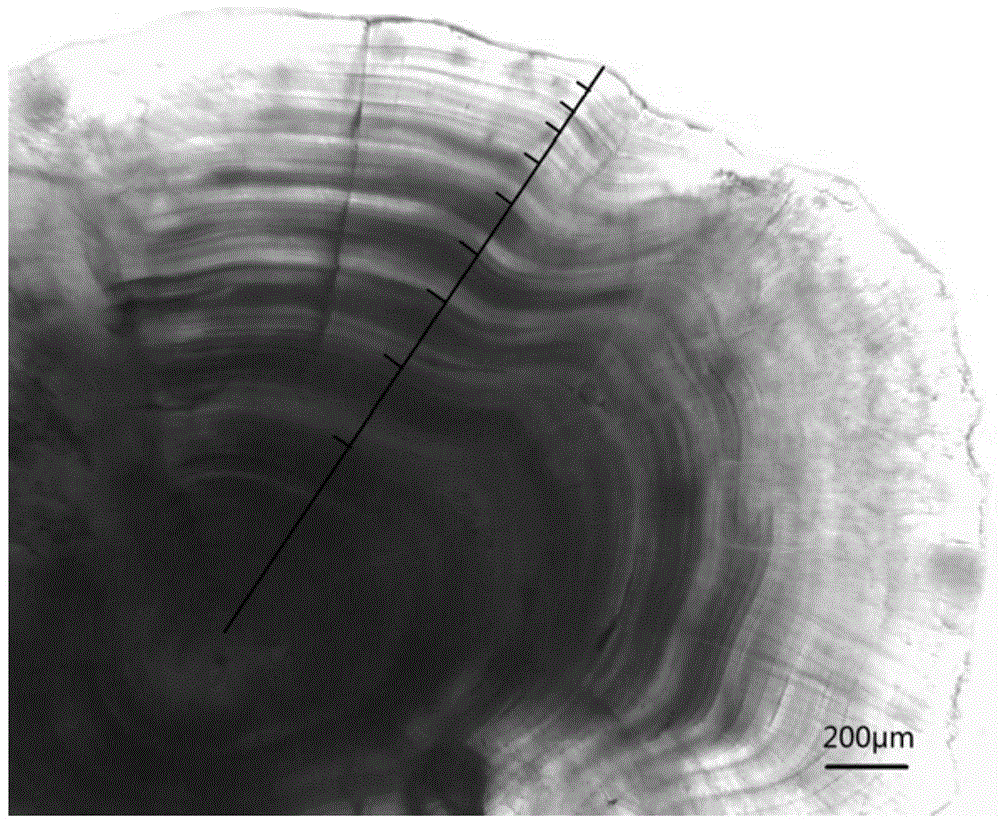

[0018] Embodiment one: a kind of preparation method of Schizothorax otolith slices is specifically completed according to the following steps:

[0019] 1. Extract otoliths: Use a scalpel and curved tweezers to remove the otoliths of Schizothorax, and then remove the dirt on the surface of the Schizothorax otoliths;

[0020] 2. Soak otoliths: put the schizothoracic otoliths from which the surface dirt has been removed in a 2mL-5mL centrifuge tube, and then add alcohol with a volume fraction of 95% to soak the schizothoracic otoliths for 2d-5d to obtain the alcohol-soaked otoliths. Schizothorax otoliths;

[0021] 3. Cleaning the otoliths: use distilled water to rinse the surface of the schizothoracic otoliths soaked in alcohol for 2 to 3 times, and then dry them at room temperature to obtain the dried schizothoracic otoliths;

[0022] 4. Fix otoliths: First, apply a layer of release agent on the bottom and side walls of the plastic mold, and then place the dried Schizothorax ot...

specific Embodiment approach 2

[0030] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the preparation method of the resin described in step 4 is as follows: mix epoxy resin and hardener, and stir at a stirring speed of 50r / min~60r / min 2min to 3min, and then stand still for 2min to 3min to obtain the resin; the mass ratio of the epoxy resin to the hardener is 25:3. Other steps are the same as in the first embodiment.

[0031] The epoxy resin described in this embodiment purchases the EpoFix resin produced in Struers (Struers), product number 40200029; Described hardener is the EpoFix that Struers produces and is used in conjunction with EpoFix resin Hardener, product number is also 40200029.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step two, place the schizothoracid otoliths from which the surface dirt has been removed in a 2mL~3mL centrifuge tube, and then add a volume fraction of 95 The otoliths of Schizothorax were soaked in 100% alcohol for 2d-3d to obtain the otoliths of Schizothorax soaked in alcohol. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com