Slip casting diffusion testing device and testing method using same

A diffusion test and grouting technology, which is used in measurement devices, suspension and porous material analysis, permeability/surface area analysis, etc. To achieve the effect of easy operation, high reusability and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

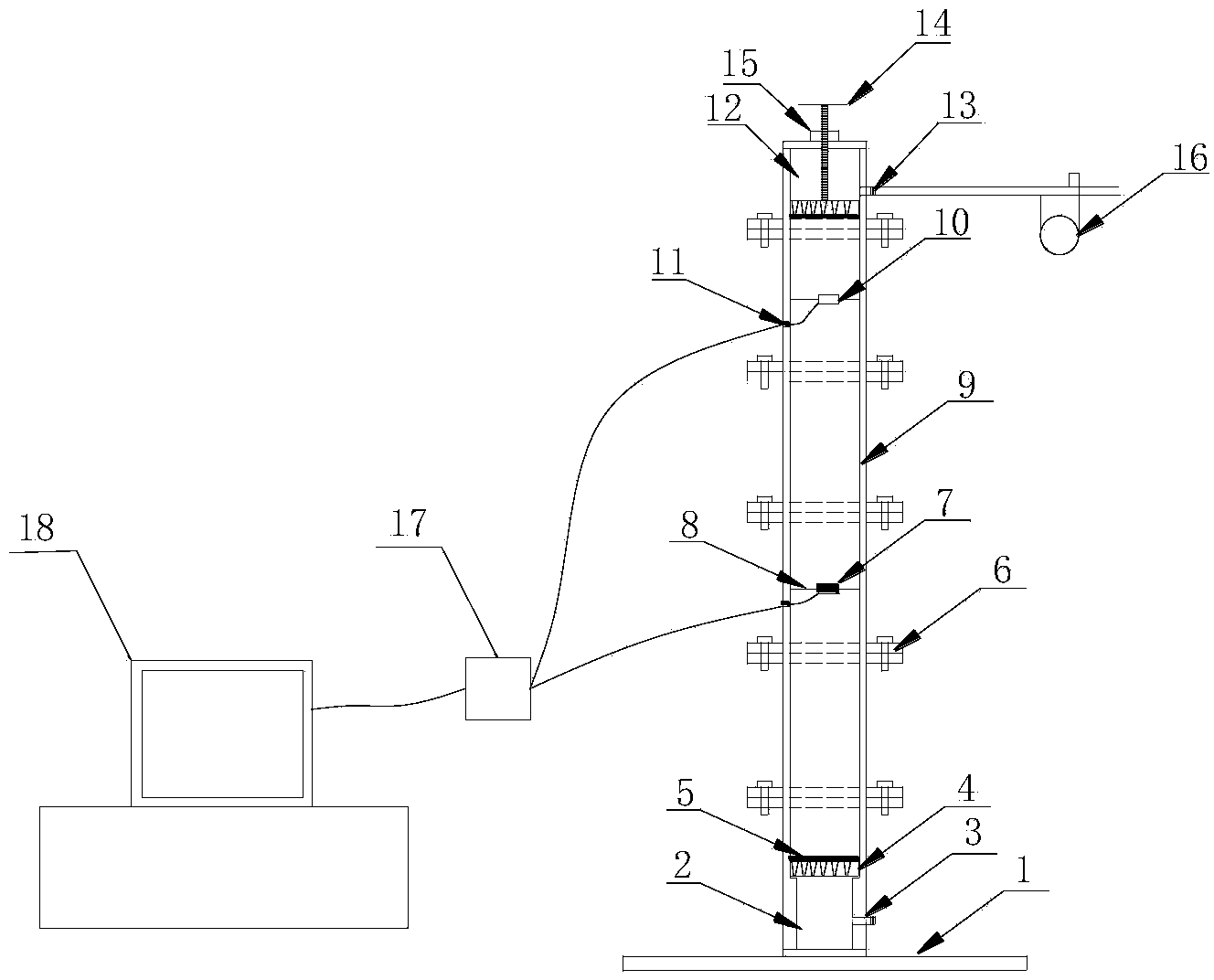

[0046] figure 1 , a new grouting diffusion test device, including a column-shaped permeation device and a monitoring system.

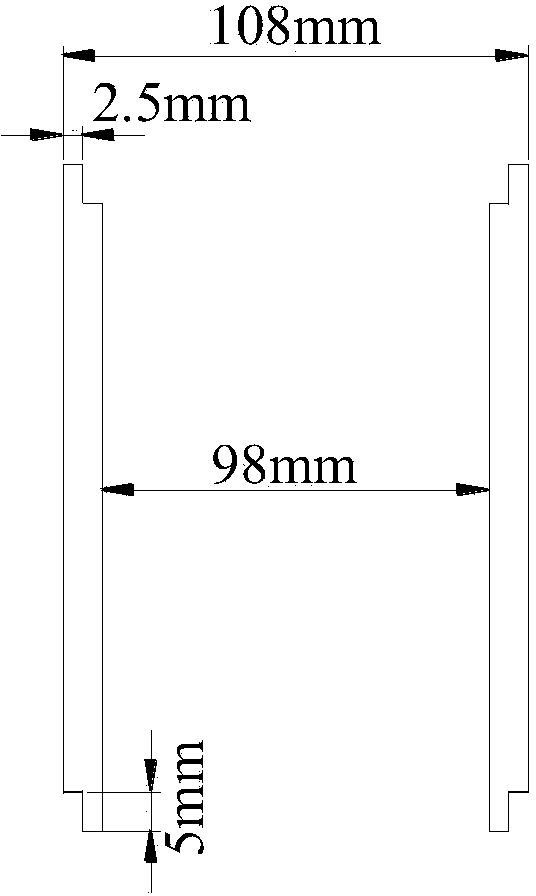

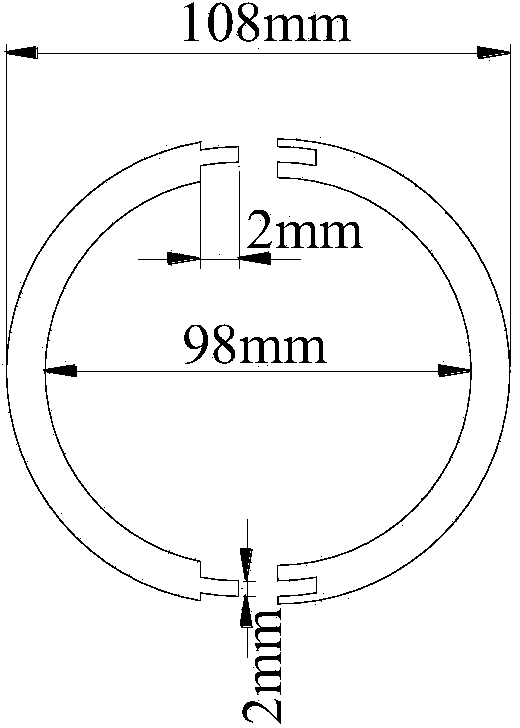

[0047]The cylindrical infiltration device is composed of a balance chassis 1, an inlet cabin 2, a steel ring welded quick clamp joint 6, a cylindrical steel pipe 9, and an outlet cabin 12 connected. The inlet compartment 2 is equipped with a perforated plate 4 and a filter screen 5. The diameter of the circular hole of the perforated plate is Φ=4mm; the cylindrical steel pipe 9 has an outer diameter of 108mm, a height of 200mm or 400mm, and a wall thickness of 5mm. The inner wall of the cylindrical steel pipe is frosted, and the upper edge is concave. The groove and the lower edge are bosses, and the cylindrical steel pipe is divided into two pieces of fastening type. The edge of the left piece is a boss, and the edge of the ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com