Optimal Control Method of Batch Reaction Process in Batch Reactor

A reaction process and optimization control technology, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as the inability to meet the control requirements of the intermittent reaction process and the lack of the ability to compensate for nonlinearity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

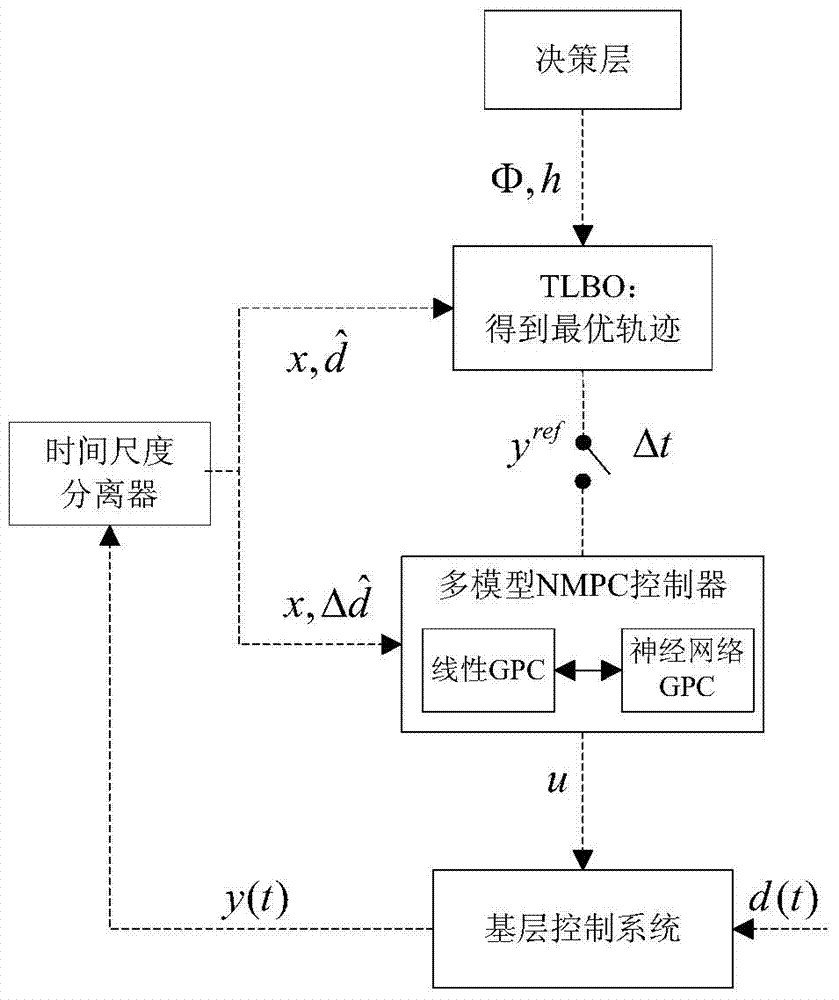

[0059] The following will combine Figure 1 to Figure 4 The optimal control method of the batch reaction process in the batch reactor provided by the present invention is described in detail, which is an optional embodiment of the present invention, and it can be considered that those skilled in the art will not change the spirit and content of the present invention. Be able to revise and polish it.

[0060] The idea of this method is to:

[0061] The entire control structure is mainly composed of three layers.

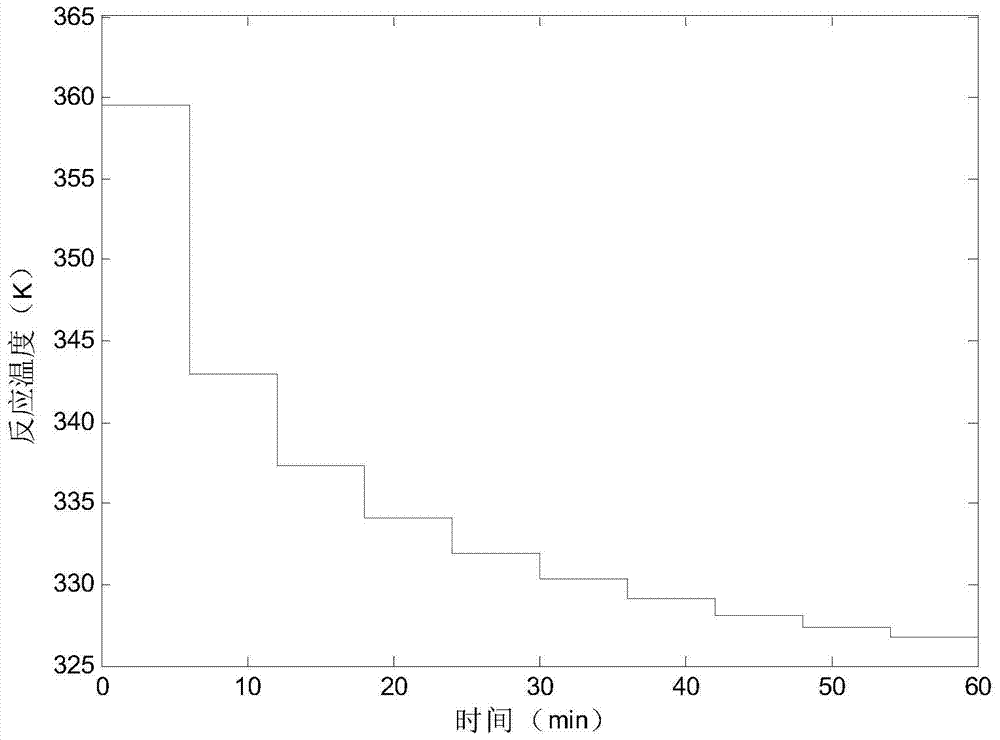

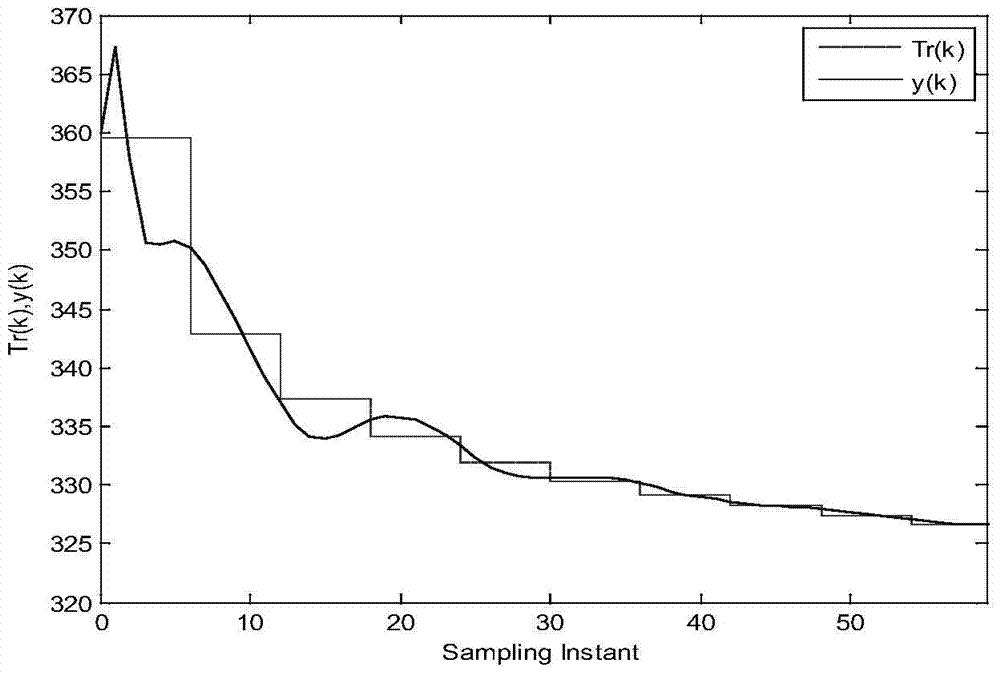

[0062] The upper structure is aimed at the optimization problem in the batch reaction process. Considering the dynamic model of the process, the TLBO algorithm is used to solve the dynamic optimization problem of the process, so as to obtain its maximum economic benefits. It is called the optimization layer. The optimization layer calculates the control object (such as: reaction temperature ) as the reference trajectory of the control layer; the lower layer struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com