Reverse air inlet heat dissipation method of bank self-service equipment

A heat dissipation method and reverse air intake technology, applied in the complete banking system, complete banking system, instruments, etc., can solve the problems of large damage to magnetic drums and rubber rollers, equipment impact, dust entry, etc., to increase heat dissipation efficiency and area, reduce contamination and damage, uniform flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

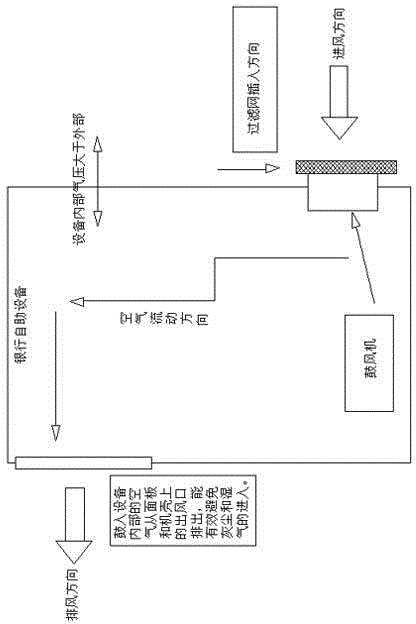

[0013] The method of the present invention is described in detail below with reference to the accompanying drawings.

[0014] In this method, a fan is used to draw air to the inside of the device to dissipate heat. Due to the air intake to the inside, negative pressure is generated inside and outside the equipment. The air pressure inside the device is higher than the outside environment. The internal air flows from the gaps of the equipment shell and the equipment inlet and outlet of the panel to the external environment for heat dissipation.

[0015] Due to the scattered distribution of the shell gap and the operation panel, the hot air is dispersed, and the negative pressure is relatively uniform inside the equipment, which can increase the heat dissipation efficiency and area of the equipment, and at the same time make the hot air more dispersed when leaving the equipment to avoid hot air. The outlet only passes through the fan channel, causing the hot air near the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com