Electric vehicle battery structure and electric vehicle

A technology for electric vehicle batteries and electric vehicles, applied to batteries, secondary batteries, structural parts, etc., can solve problems such as excessive wires and inconvenient connections, and achieve the effects of good integrity, enhanced stability, and rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

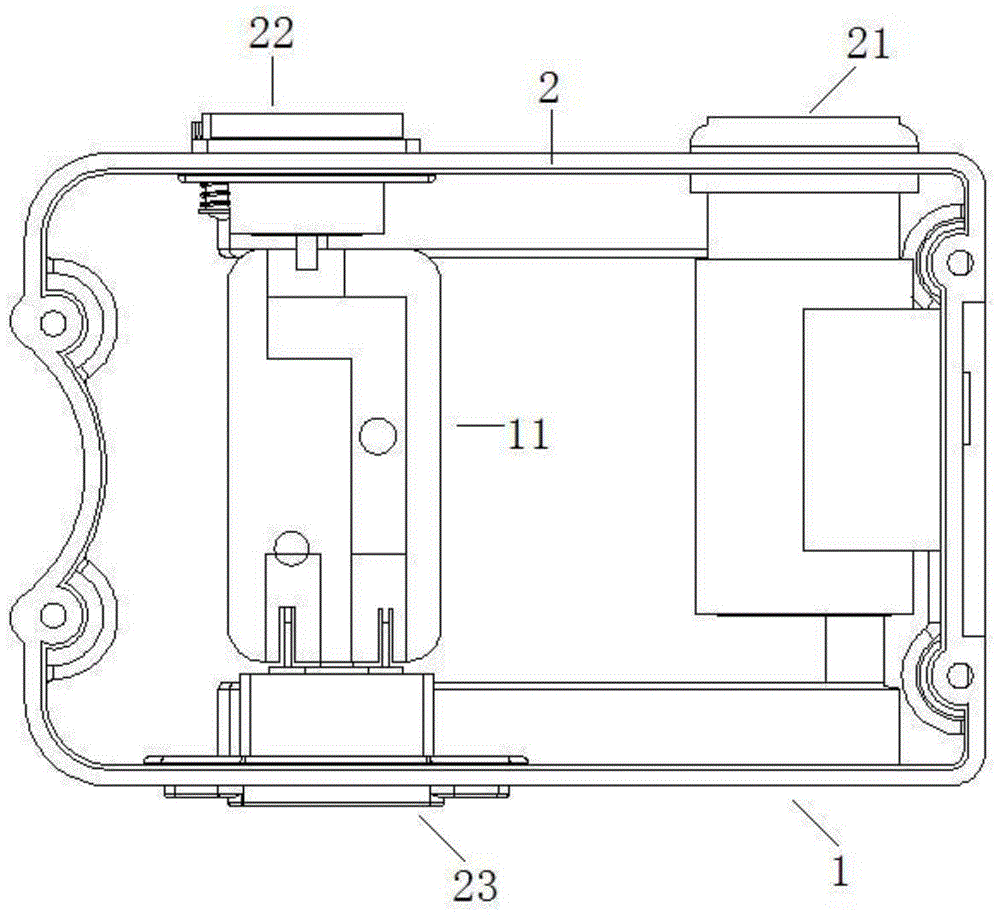

[0026] Embodiment 1: as figure 1 , figure 2 , image 3 In the shown embodiment, an electric vehicle battery structure includes several battery unit bodies 1, the battery unit body 1 includes a casing 2, and the casing 2 includes a left bottom case and a right bottom case. 2. There are BMS, battery pack, and PCB board 11 inside. All battery tabs on the battery pack are welded to the PCB board 11. The PCB board 11 is electrically connected to the BMS. The upper cover is provided with a parallel The external charge and discharge port 23 and the internal electrical connection port 12 are both connected to the battery pack through positive and negative wires, and an outgoing line is provided on the right bottom shell The positive and negative wires are drawn out of the casing 2 through the outlet port. The outlet port is provided with a rubber plug with two holes, and the positive and negative wires are respectively connected through the two holes of the rubber plug. The intern...

Embodiment 2

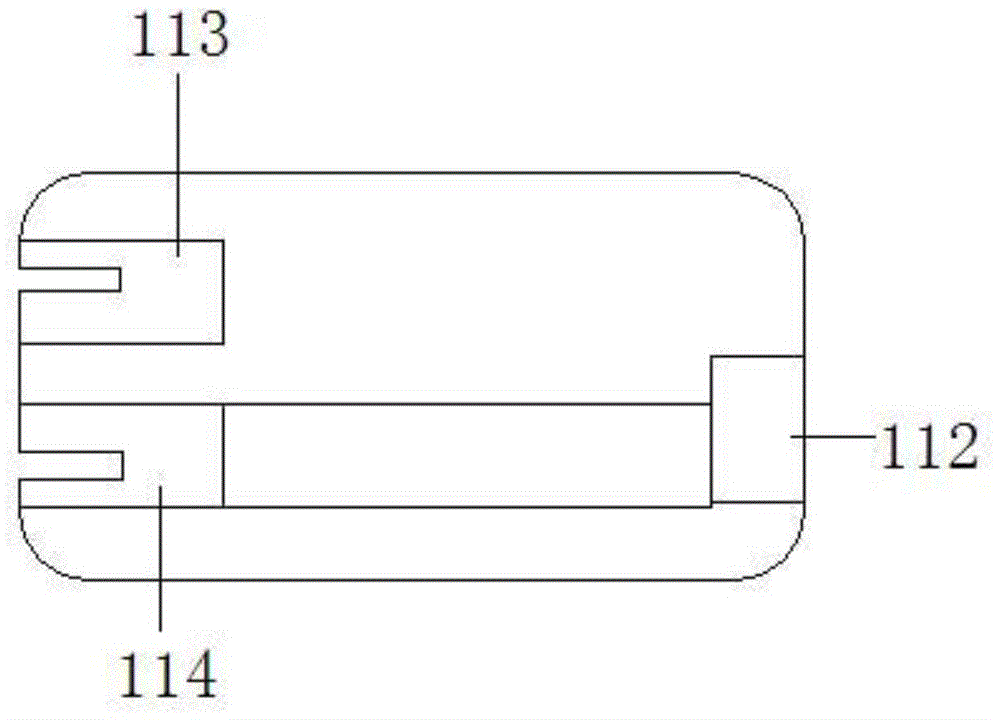

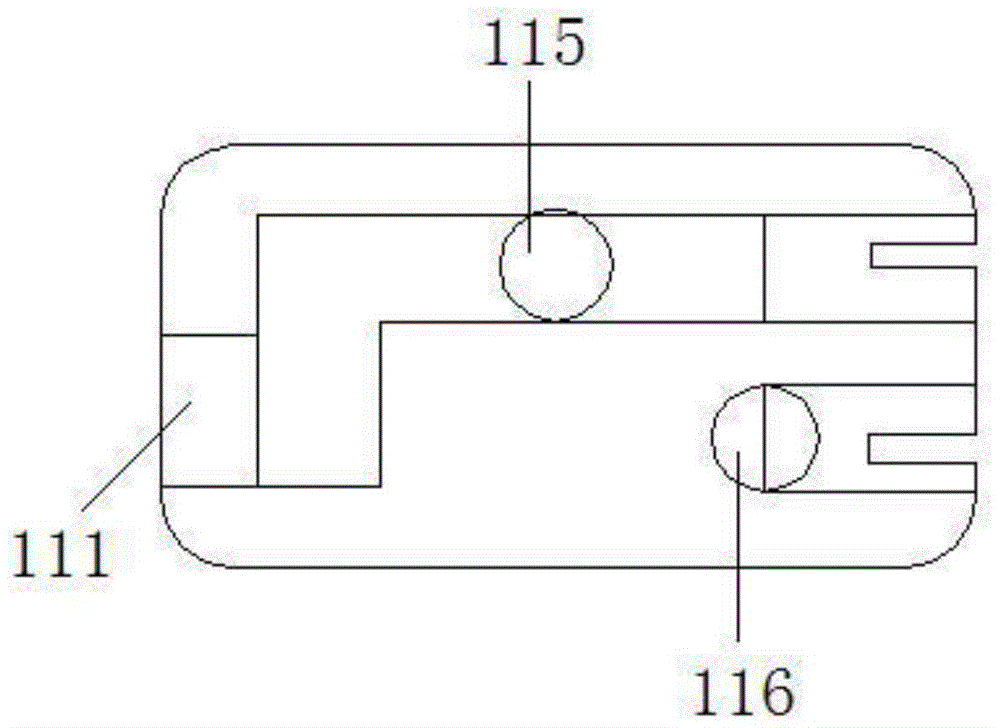

[0028] Embodiment 2: the basic structure and implementation mode of this embodiment are basically the same as embodiment 1, the difference is that, as Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9As shown, the shell 2 is provided with an internal electrical connection port 12, the internal electrical connection port 12 is connected in parallel with the line where the charging port 22 and the discharge port 23 are located, and the internal connection between the battery cells 1 The connecting wires are all directly drawn from the internal electrical connection port 12. The internal electrical connection port 12 can be used to connect the battery unit bodies 1, avoiding confusion of lines, and improving the convenience and effect of connection. One battery unit body 1 is connected to another battery unit body 1 through a connecting frame, the connecting frame includes a tube frame 3, two pairs of locking pins 4 slidingly connected with the tube frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com