Novel motor rotor structure

A motor rotor, a new type of technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of increasing assembly difficulty and process, wasting materials, reducing assembly efficiency, etc., to save motor space and improve Assembly efficiency, material cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

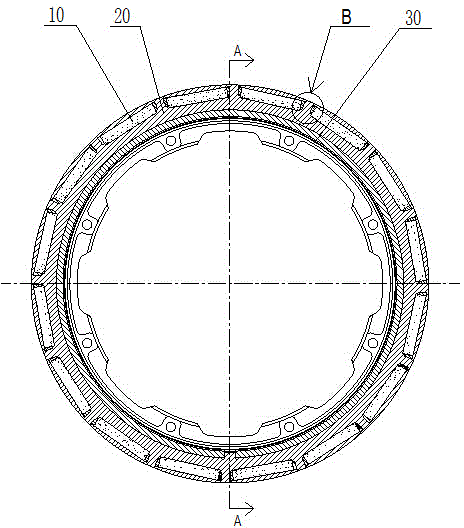

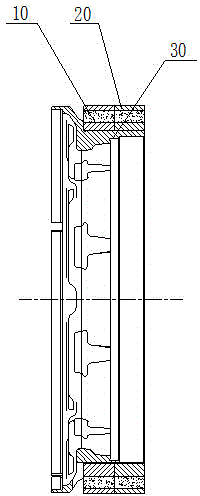

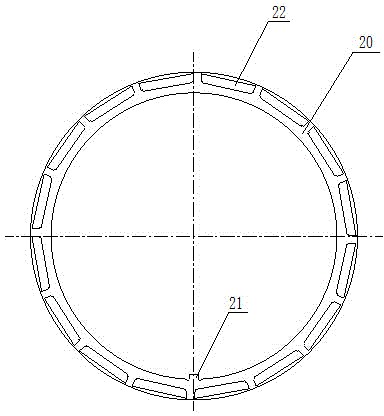

[0019] A new type of motor rotor structure, including a ring-shaped punch 20, a positioning key 21 is arranged on its inner circle, a keyway 31 matching with the positioning key 21 is provided on the outer ring of the rotor bracket 30, the punch 20 and the rotor The outer ring of the bracket 30 has an interference fit, and the punch 20 has a plurality of slots 22 for inserting the magnet 10 along its circumference. The magnet 10 and the punch 20 have an interference fit. Injection plastic 40 is filled in the slot 22 gap between punching sheet 20, as figure 1 , 2 , 5 shown.

[0020] Such as figure 1 , 4 As shown, the outer ring of the rotor bracket 30 is an annular retaining wall 32 arranged on the rotor bracket 30, the inner circular surface of the punch 20 is closely attached to the outer circular surface of the annular retaining wall 32, and is arranged on The positioning key 21 on the inner circle of the punching piece 20 matches with the keyway 31 provided on the annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com