Microwave reaction device using coaxial leaky antenna and application of microwave reaction device using coaxial leaky antenna

A microwave reaction and crack antenna technology, applied in the microwave field, can solve problems such as instrument damage, probe breakdown, uneven microwave distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

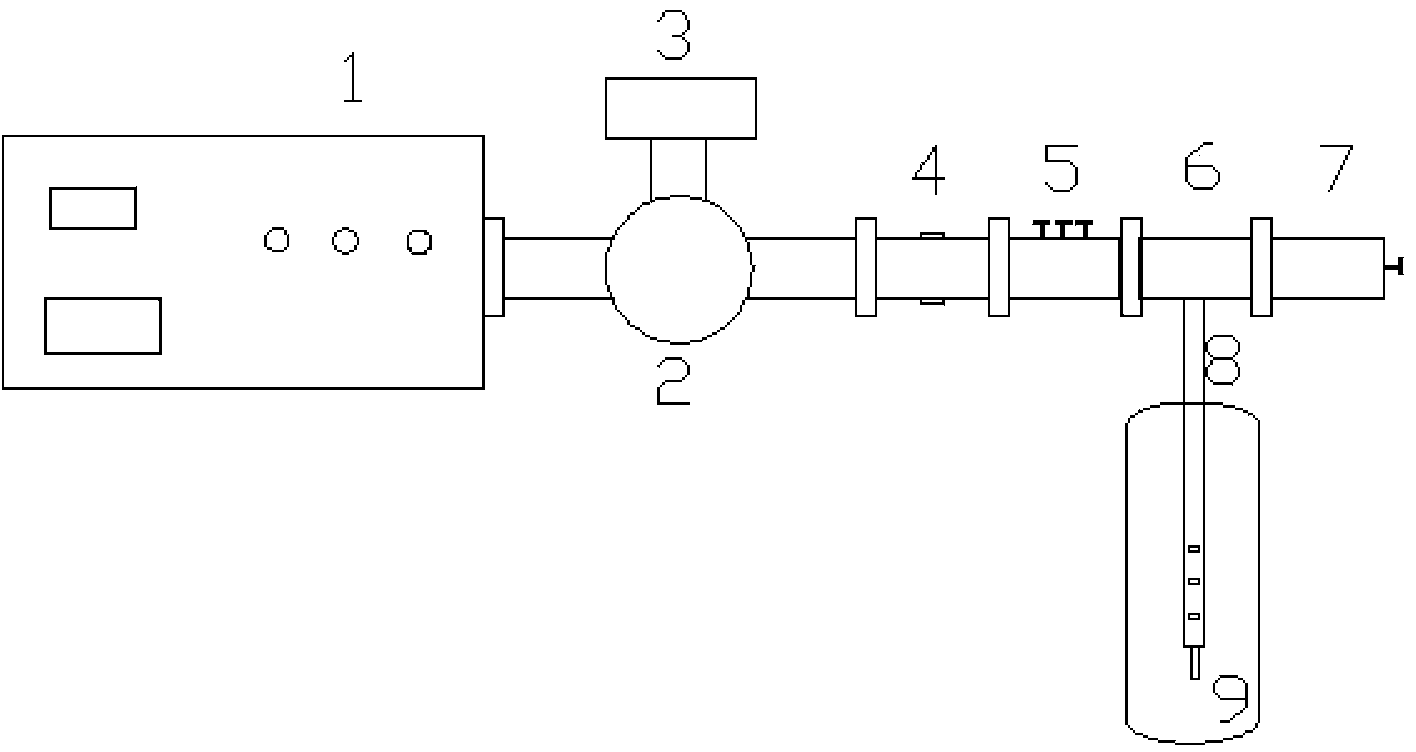

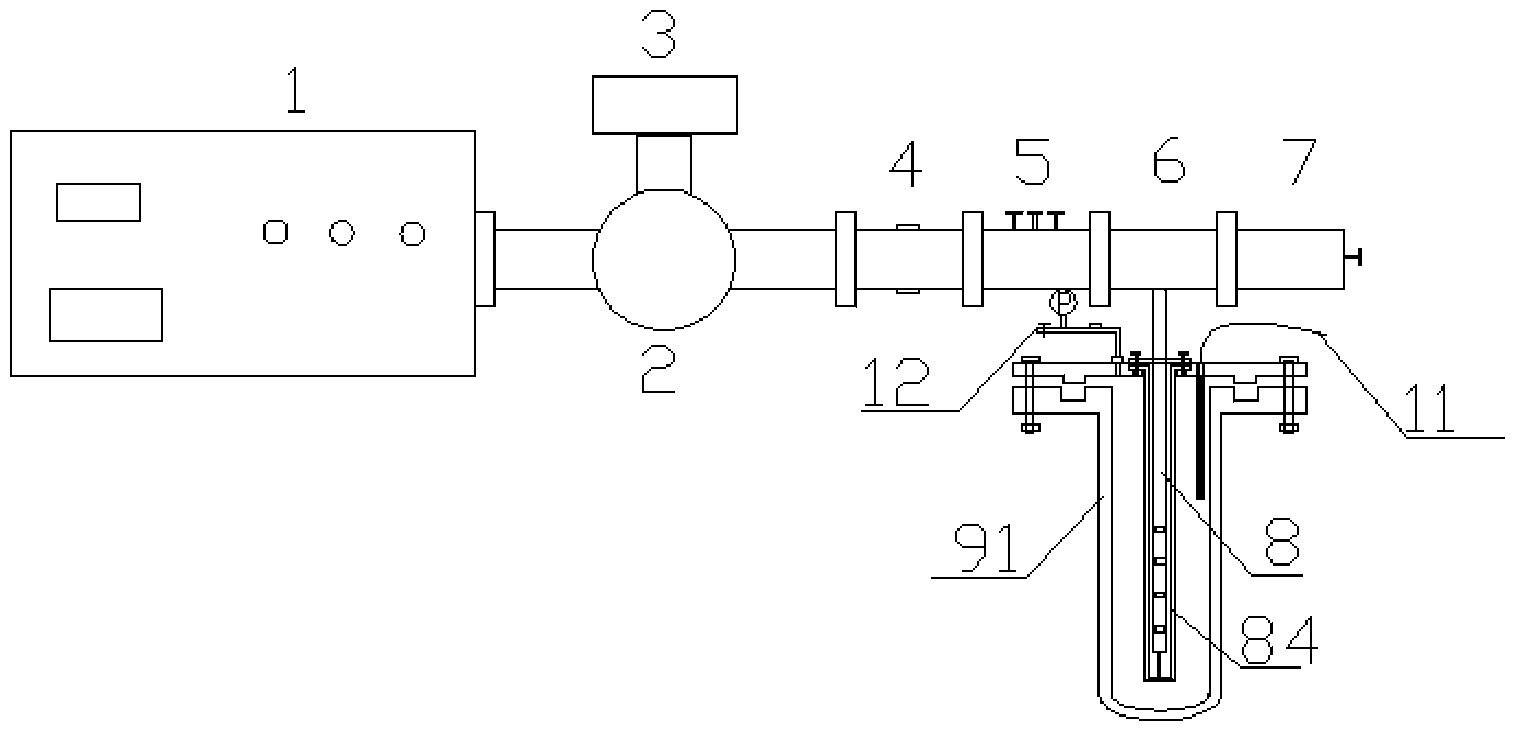

[0101] Example 1: Detection of Microwave Distribution Uniformity

[0102] according to image 3 As shown, connect No. 2 microwave reaction device (wherein, the reactor part is composed of Figure 7 replace the structure shown), put the coaxial antenna into the intermittent stirred reactor of the No. 2 device with 3L deionized water, without stirring, turn on the microwave power supply under normal pressure, and set the power to 2×1.5 kW, adjust the three-screw adjuster and the terminal short-circuit adjuster to maximize the incident / reflected current ratio. During the radiation process, multiple optical fiber thermometers are used to detect the temperature at different positions at the same time. The maximum temperature difference in the circumferential direction of the antenna is 0.3°C. The maximum temperature difference in the vertical direction is 0.8°C, the maximum temperature difference in the radial direction of the antenna is 2.7°C, and the maximum temperature differen...

Embodiment 2

[0107] Embodiment 2: the application of stirring type reactor

[0108] (1) Atmospheric pressure application and scale up

[0109] Put 0.5mol benzaldehyde, 0.5mol acetophenone, 0.25mol sodium hydroxide and 250mL deionized water into the intermittent stirring reactor of No. 1 microwave reaction device, according to image 3 Connect the microwave reaction device as shown and connect the condensing reflux system, set the stirring speed to 200rpm, turn on the microwave power source under normal pressure, set the power to 3kW, and measure the temperature with an optical fiber thermometer during the heating process. After the reaction solution boiled, the power was adjusted to reflux the reaction solution for 40 min. After the reaction, the microwave power source was turned off, and the reaction solution was processed to finally obtain chalcone with an isolated yield of 88%.

[0110] 5mol benzaldehyde, 5mol acetophenone, 2.5mol sodium hydroxide and 2.5L deionized water are dropped i...

Embodiment 3

[0118] Embodiment 3: the application of internal circulation reactor

[0119] Put 0.4mol of malononitrile, 0.2mol of acetophenone and 300mL of deionized water into the batch-type internal circulation reactor of No. 1 microwave reaction device, according to image 3 The microwave reaction device connected as shown (wherein, the reactor part is composed of Figure 5 The structure shown is replaced) and connected to the condensing reflux system. Under normal pressure, turn on the microwave power source, set the power to 3kW, and measure the temperature with an optical fiber thermometer during the heating process. After the reaction solution boils, adjust the power to make the reaction solution boil and circulate for 40 minutes. After the reaction was completed, the microwave power source was turned off, and the reaction solution was processed to finally obtain 2-(1-phenylethylidene)malononitrile with an isolated yield of 85%.

[0120] 4mol of malononitrile, 2mol of acetophenone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com