Method for protecting non-processed workpiece surface by utilizing passivation metal coating in electrochemical machining

A metal coating and workpiece surface technology, applied in the direction of electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problem that the influence of stray corrosion cannot be fundamentally eliminated, and solve the problem of stray corrosion. It is widely applicable and The effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

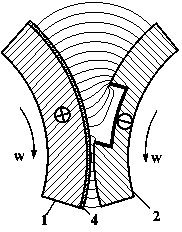

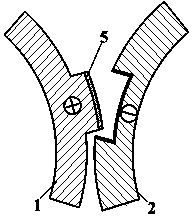

[0022] figure 1 It is a schematic diagram of stray corrosion in different electrolytic machining. It can be seen that stray corrosion is ubiquitous in electrolytic machining, and stray corrosion leads to poor forming accuracy of processed workpieces.

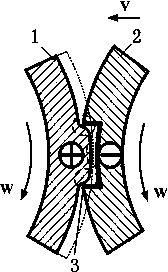

[0023] combine figure 2 , 3 , illustrate the implementation process of the present invention:

[0024] (1) Apply a layer of passivating metal coating on the entire initial workpiece surface by thermal spraying technology or electrochemical deposition method; since the applied passivating metal coating may have a small amount of corrosion on the non-processed surface, the coating The thickness of the layer can be slightly adjusted according to the amount of corrosion;

[0025] (2) Use electrolytic machining to remove workpiece material in the machining area;

[0026] (3) After processing, remove the passivating metal coating with passivating properties;

[0027] (4) Clean the parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com