Pressing welding device and process for high-power optical fiber laser welding speed changer gear

A transmission gear and fiber laser technology, applied in laser welding equipment, auxiliary devices, welding equipment, etc., can solve the problems of high production efficiency, low production cost, low production efficiency of transmission gear, etc., and achieve improved processing efficiency, good connection, The effect of reducing labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

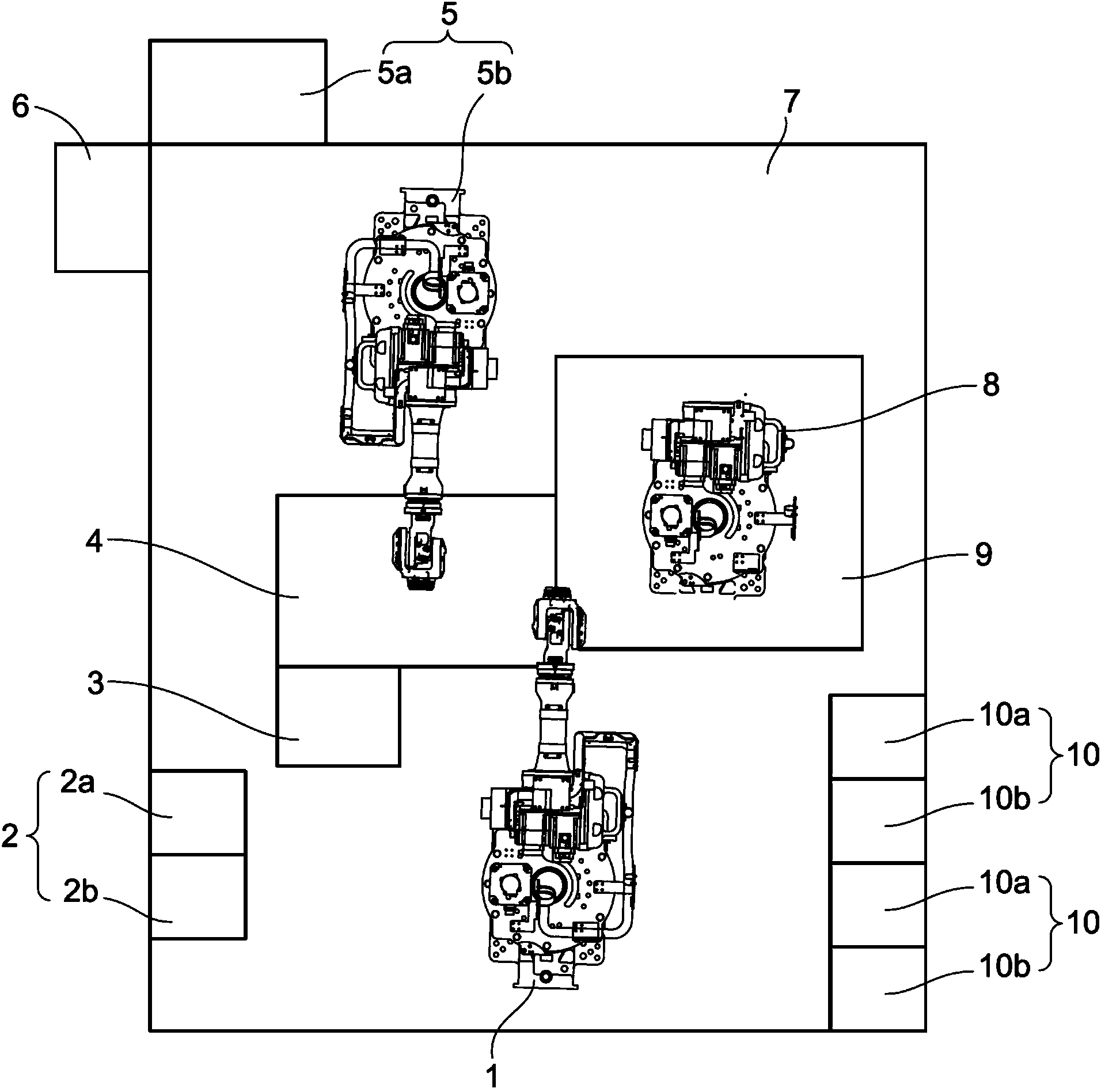

[0031] refer to figure 1 , Figure 8 , a press-fit welding device for high-power optical fiber laser welding transmission gears of the present invention includes a workbench 7 and a control cabinet 6, and the workbench 7 is provided with a laser welding mechanism 5, a press-fit mechanism 8, a handling mechanism 1 and a loading and unloading mechanism. The station 2 and the control cabinet 6 are respectively connected with the laser welding mechanism 5, the pressing mechanism 8, and the conveying mechanism 1. The welding station 4 is arranged under the laser welding mechanism 5, and the pressing station 9 is arranged under the pressing mechanism 8. The laser welding mechanism 5 comprises a laser welding robot 5b and a fiber laser 5a, the laser welding robot 5b is connected with the fiber laser 5a, the laser water cooler required for the fiber laser 5a in use is also arranged around the workbench 7, and a gas cylinder is stored. The gas cylinder storage area and the workbench 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com