Accurate positioning, welding and conveying device

A conveying device and precise positioning technology, applied to conveyors, auxiliary devices, welding equipment, etc., can solve problems such as poor stability, increased manufacturing costs, and complex structural design, and achieve simple structure, easy operation and maintenance, and safe performance reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

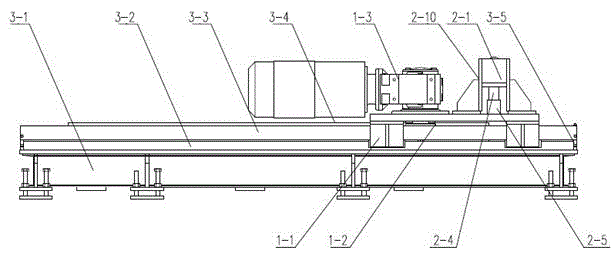

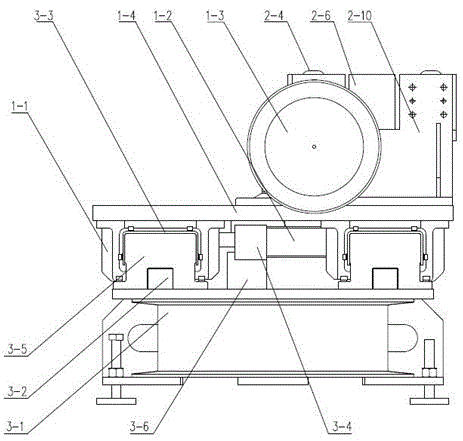

[0022] Such as Figure 1-Figure 4 As shown, a precise positioning welding conveying device is composed of a power transmission mechanism, a positioning pin mechanism and a track mechanism;

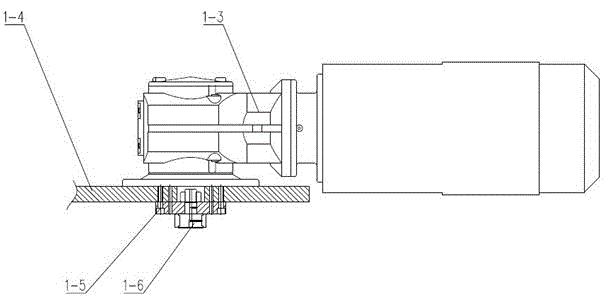

[0023] The power transmission mechanism includes a track connecting seat 1-1, a travel gear 1-2, a driving motor 1-3, a main body mounting seat 1-4, a guide wheel mounting plate 1-5 and a track roller 1-6. The track connecting seat 1-1 is installed on the main body mounting seat 1-4 by bolt connection, the travel gear 1-2 is connected with the driving motor 1-3 through central positioning, and the driving motor 1-3 is installed on the main body through bolt connection On the mounting seat 1-4; and the guide wheel mounting plate 1-5 is connected with the main body mounting seat 1-4 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com