Inner cooling damping heat-shrinkable tool bar device

A technology of tool holder and heat shrinking, which is applied in positioning devices, milling cutters, clamping, etc., can solve the problems that do not involve heat shrinking tool holders and tool cooling, unbalance and vibration, etc., and achieve simple and reliable structure , good rigidity and good interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

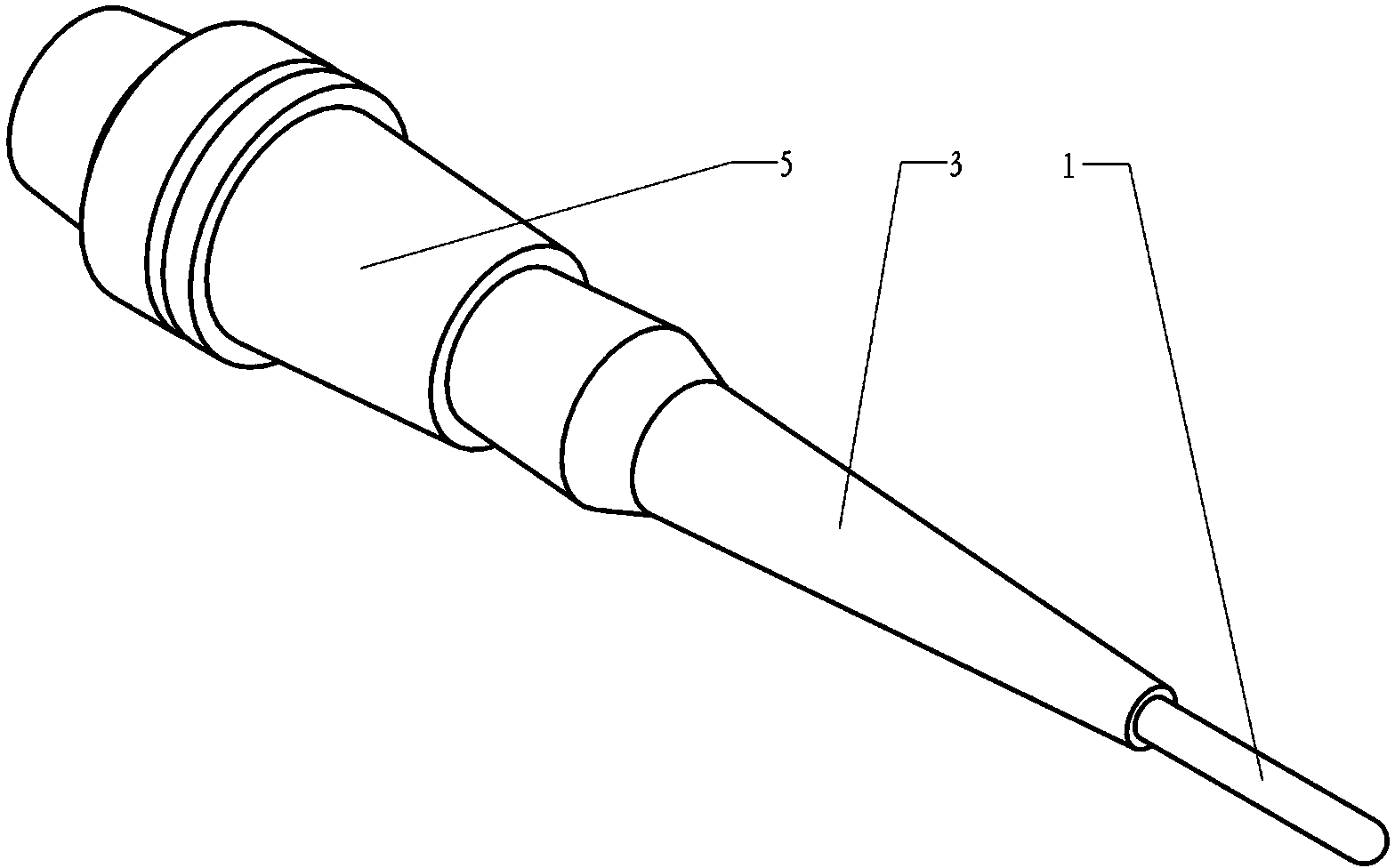

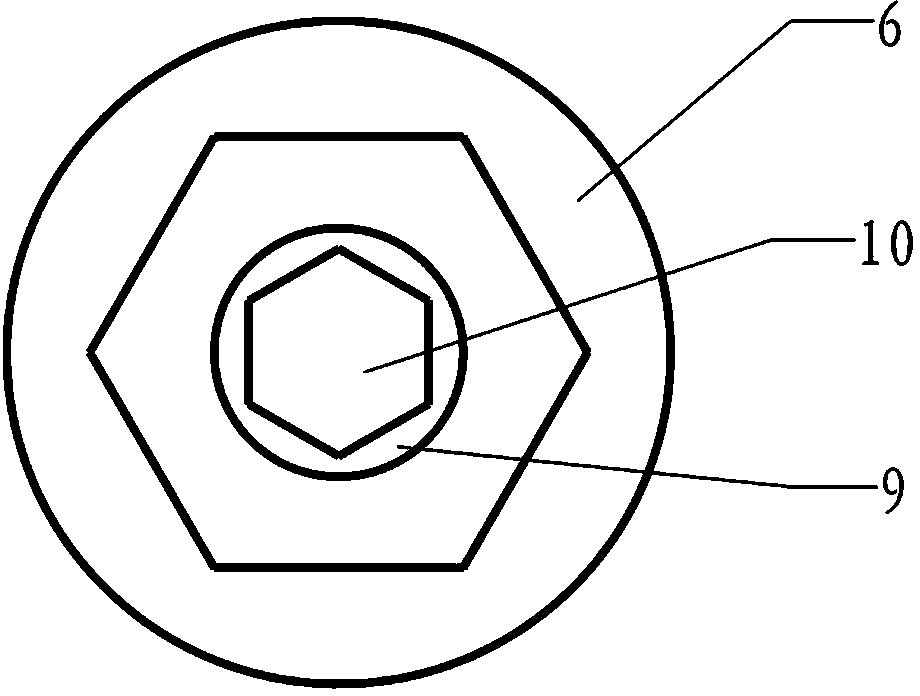

[0022] Example 1, such as figure 1 As shown, it includes a handle 5, a heat-shrinkable tool holder 3 and a tool 1; the inner end of the handle 5 is a shape structure matched with the spindle of the machining center, the handle 5 is designed as a hollow structure, and the handle 5 is a hollow cavity The waist is a screw through-hole structure with an inner diameter smaller than the inner diameter of both ends that matches the outer diameter of the connecting screw 6, and the outer end of the knife handle 5 is a tapered cavity structure that expands outward; The taper cavity at the outer end of the tool handle 5 is a tapered structure, and the inner end is provided with a screw hole; the inner end of the heat-shrinkable tool holder 3 is set in the outer end taper cavity of the tool handle 5, and the connecting screw rod 6 is used The inner end of the tool handle 5 is inserted through the through hole of the screw rod and connected with the screw hole provided at the inner end of...

Embodiment 2

[0023] Embodiment 2, in order to solve the technical problems encountered in lengthening the heat-shrinkable blade, the heat-shrinkable blade 3 of the present invention can adopt a double-cone structure with gradually smaller ends and a thicker waist. Compared with the traditional handle-knife mechanism, the length and size of the heat-shrinkable tool holder in the present invention are designed in series, and the rigidity is better, which makes the present invention can select suitable sizes according to different processing environments. Heat Shrink Arbor. refer to Figure 1 to Figure 6 , all the other are with embodiment 1.

Embodiment 3

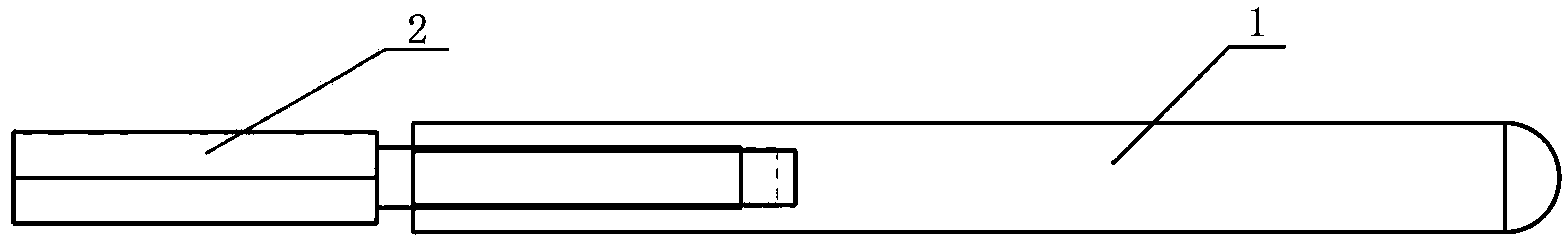

[0024] Embodiment 3, in order to improve the heat dissipation effect, the present invention may also be connected with a heat dissipation core 2 at the inner end of the cutting tool 1, and the heat dissipation core 2 may be a copper heat dissipation core with good thermal conductivity. The tail of the heat dissipation core 2 can also be designed as a wing structure to increase the heat dissipation area. refer to Figure 1 to Figure 6 , all the other are with above-mentioned embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com