wood processing bed

A wood and workbench technology, applied in metal processing equipment, grinding machines, manufacturing tools, etc., can solve the problems of not fully automatic grinding processing, inconvenient grinding, and heavy wood, so as to avoid secondary damage and improve production efficiency. , processing accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

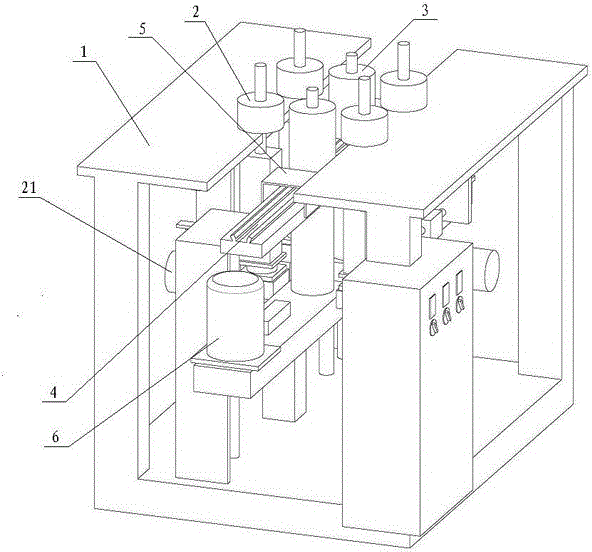

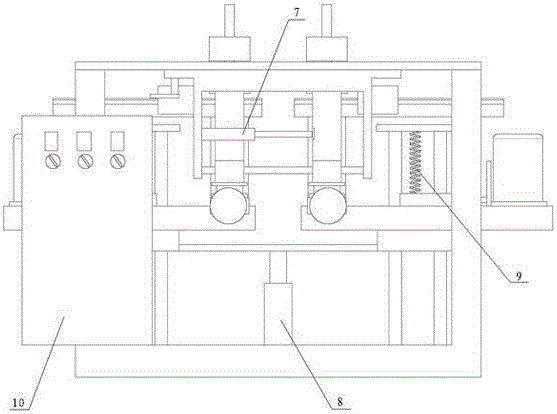

[0030] Such as figure 1 As shown, this embodiment provides a wood processing bed, including a transmission mechanism, a grinding mechanism and a worktable 1, the transmission mechanism includes 4 transmission rollers 2, the central axis of the transmission rollers 2 is perpendicular to the workbench 1, and the transmission rollers 2 cooperate to form The opposite unilateral conveyor belt, and the number of conveying rollers 2 on the unilateral conveying belt is 2, and the two conveying rollers 2 on the same unilateral conveying belt are respectively at the beginning and end of the unilateral conveying belt, and each group of conveying rollers 2 Air cylinders 7 are arranged between them, so that the gap between the conveying rollers 2 is variable, and the two cylinders 7 work synchronously, so that the gap between the two unilateral conveyor belts is variable. There is a gap for the wood to pass between the two unilateral conveyor belts, and a transmission motor 21 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com