Three-dimensional engraving machine

A three-dimensional engraving machine and frame technology, applied in decorative arts, processing models, etc., can solve the problems of unsmooth sliding of the engraving machine, low transmission precision, and difficult realization of the engraving machine, and achieve stable tool holder, strong applicability, Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

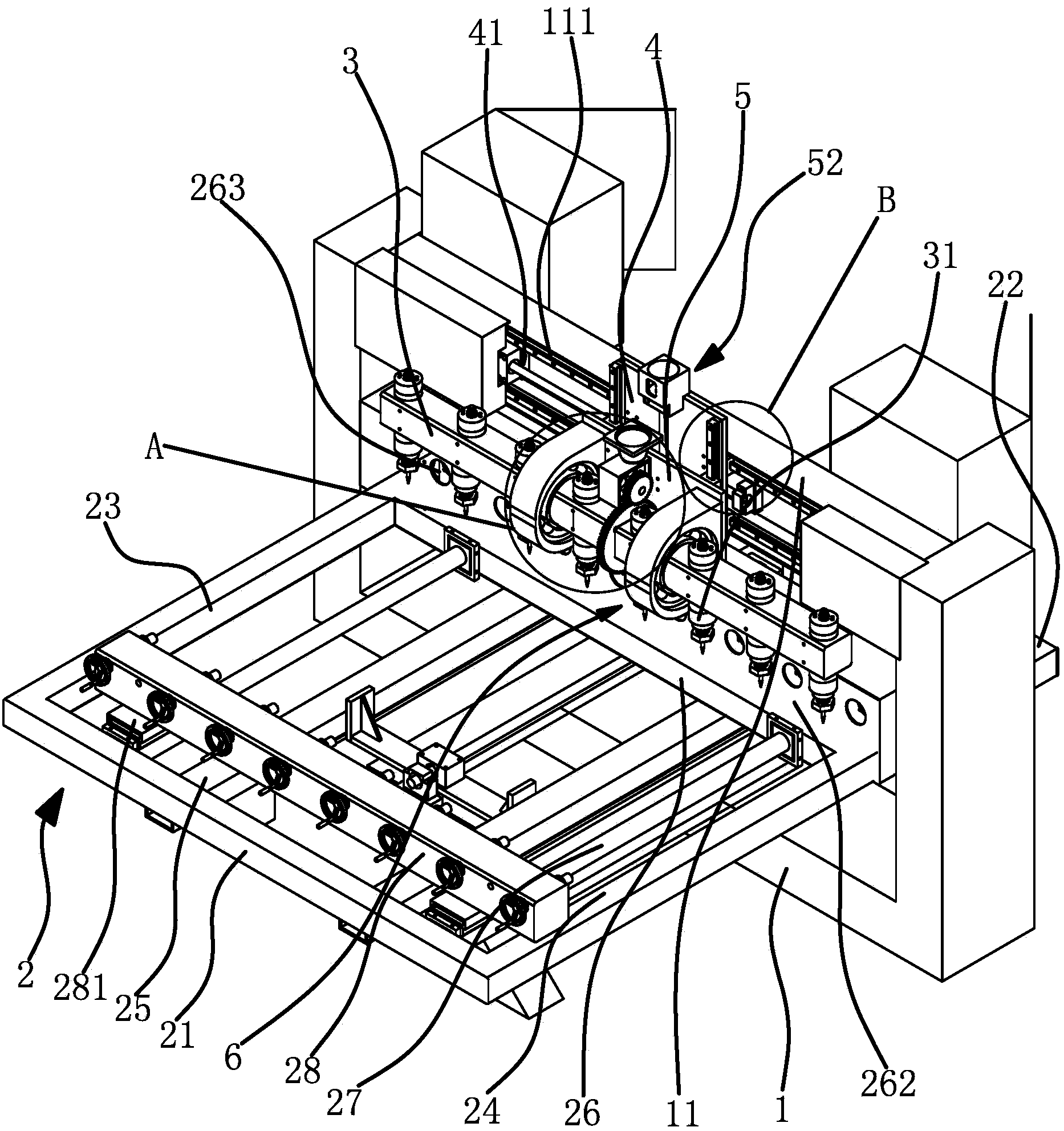

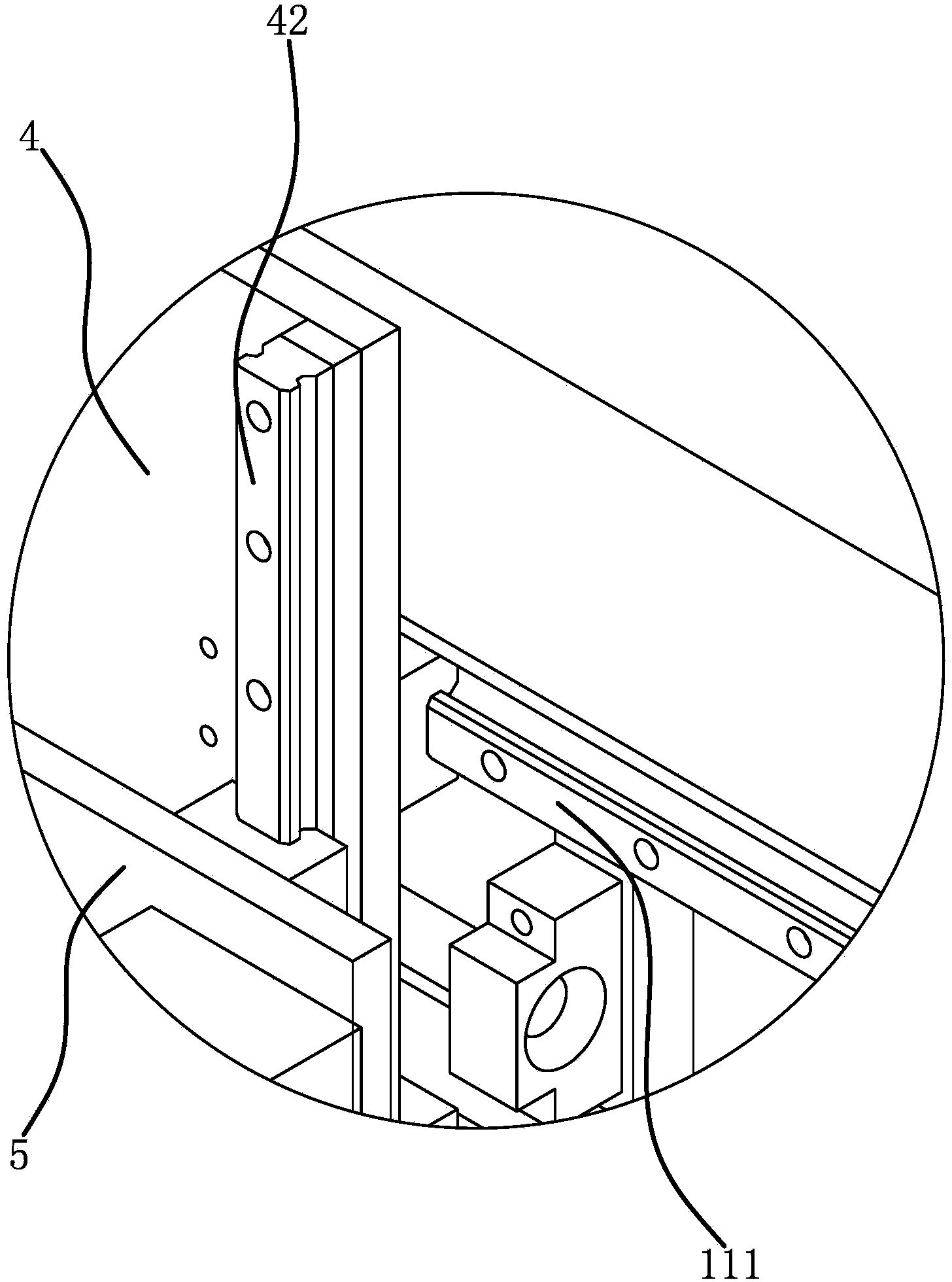

[0031] Such as figure 1 As shown, a three-dimensional engraving machine is used for engraving cylindrical workpieces, including a frame 1 and a workbench 2. The workbench 2 is arranged on the frame 1 and can move back and forth along the horizontal and vertical directions. The longitudinal direction of the platform 2 is fixed on the workbench 2, and a plurality of workpieces are arranged along the transverse direction of the workbench 2. There is a crossbeam 11 arranged horizontally along the top of the workbench 2, and the side of the crossbeam 11 is provided with a tool holder 3, and the tool holder 3 is elongated, and is used to install some cutters 31, that is, the machine head. One workpiece is opposite, that is, one cutter 31 is responsible for the engraving of one workpiece. On the side of the beam 11, there is a horizontal carriage 4 that can reciprocate horizontally and horizontally. On the horizontal carriage 4, there is a vertical carriage 5 that can reciprocate al...

Embodiment 2

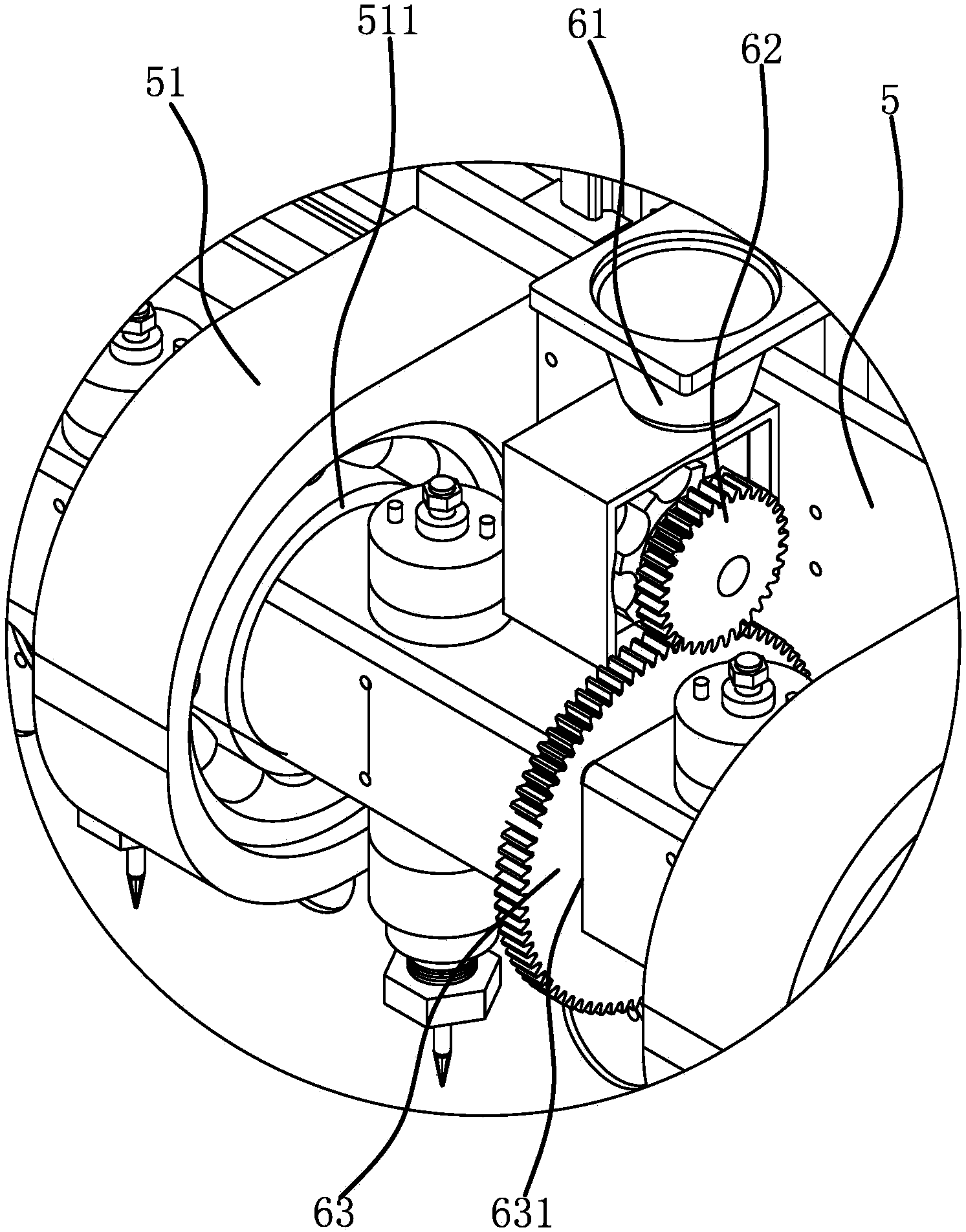

[0037] The structure of the three-dimensional engraving machine is basically the same as that of Embodiment 1, the difference is that Figure 5 As shown, the driving mechanism 6 includes a motor 61, a worm screw 65 fixed on the rotating shaft of the motor 61 and coaxial with the rotating shaft of the motor 61, and a worm wheel 64 fixed on the tool rest 3, the worm wheel 65 is engaged with the worm wheel 64, and the worm wheel 65 The length direction of the worm gear is vertically downward and meshed with the worm gear, and the worm gear is fixed on the tool holder 3 and coaxial with the tool holder 3, so the rotation of the worm screw 65 can be converted into the rotation of the worm gear, and the structure is stable.

Embodiment 3

[0039] The structure of the three-dimensional engraving machine is basically the same as that of Embodiment 1, the difference is that Figure 6 As shown, the driving mechanism 6 includes a motor 61, a driving pulley 66 fixed on the rotating shaft of the motor 61 and a driven pulley 67 fixed on the tool rest 3, and the driven gear 63 is a driven belt whose diameter is greater than that of the driving pulley 66 Wheel 67, driving pulley 66 and driven pulley 67 are connected by transmission belt 68, that is, tool holder 3 is connected and driven by transmission belt 68, which has good speed regulation ability, and simple and effective structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com