Full-automatic stacking machine

A palletizer, fully automatic technology, applied in the stacking of objects, destacking of objects, loading/unloading, etc., can solve the problems of high maintenance costs, troublesome maintenance and disassembly, affecting the quality of workpieces, etc., and achieve convenient disassembly and maintenance. , low cost, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

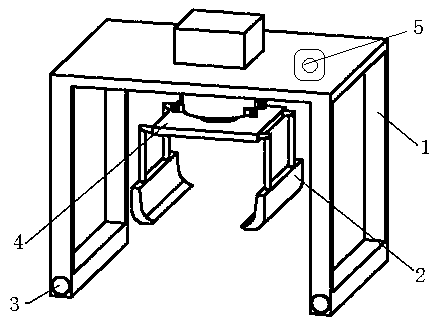

[0015] Example 1: see figure 1 , a fully automatic stacker, the stacker includes a stacker body 1, a moving part 3 arranged under the stacker body 1, the stacker also includes a lifting device 4 and a clamping device 2, The clamping device 2 is arranged below the lifting device 4 . The technical solution realizes automatic palletizing operation, greatly improves production efficiency, guarantees product quality, improves working conditions, and reduces production costs of enterprises.

Embodiment 2

[0016] Example 2: see figure 1 , as an improvement of the present invention, the clamping device 2 is set as a pair of interactive claws, and the claws are set in an L shape. In this way, the workpiece can be clamped more conveniently. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0017] Example 3: see figure 1 , as an improvement of the present invention, the lifting device 4 is set as a lifting cylinder. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com