Weather-resistant impact-resistant polyvinyl chloride wood-plastic construction formwork and preparation method thereof

A polyvinyl chloride and building formwork technology, applied in the field of building formwork, can solve the problems of reduced cycle times, increased use costs, and poor low-temperature impact performance, and achieve increased cycle times, reduced use costs, and good low-temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

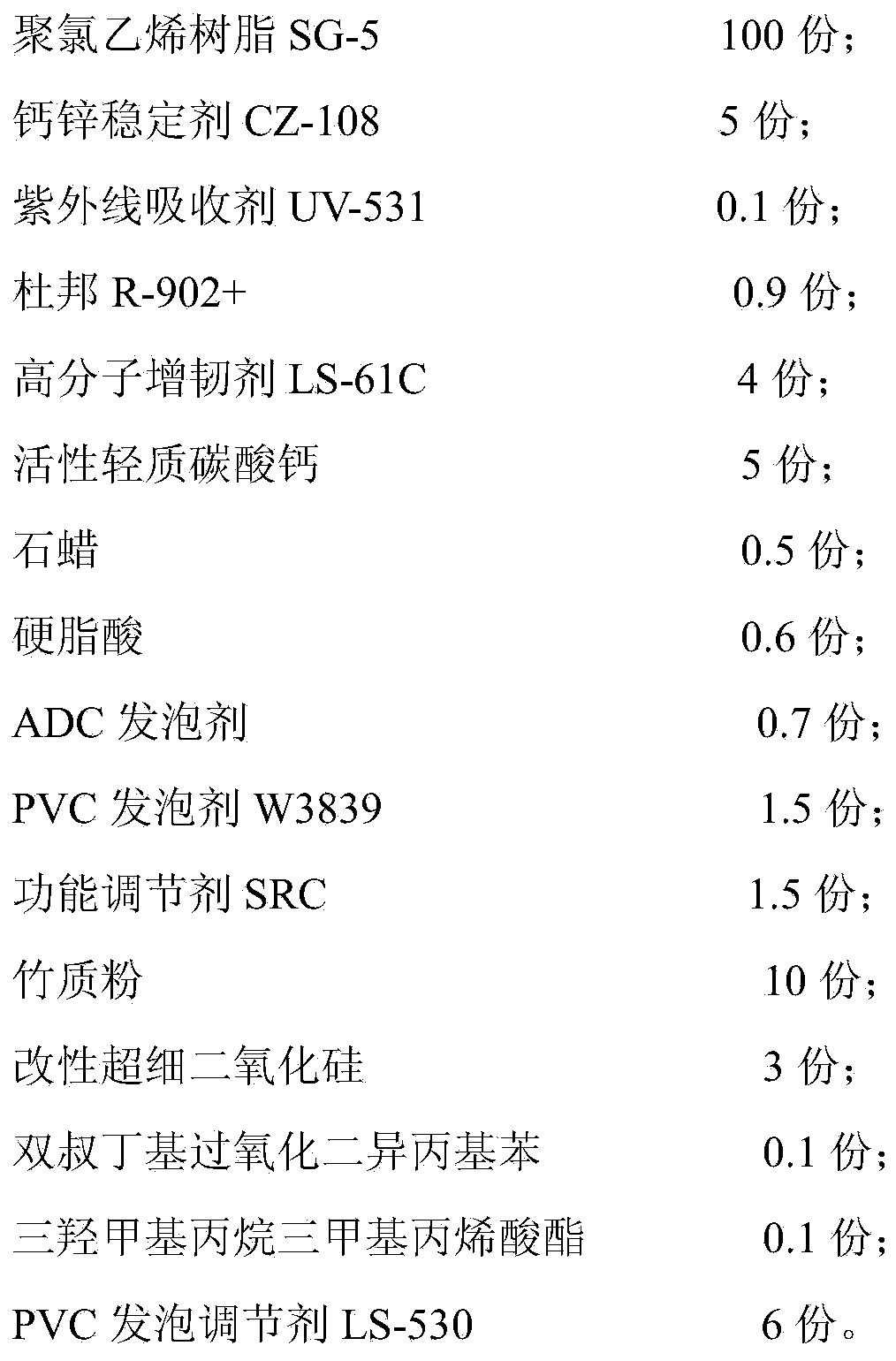

Method used

Image

Examples

Embodiment 1

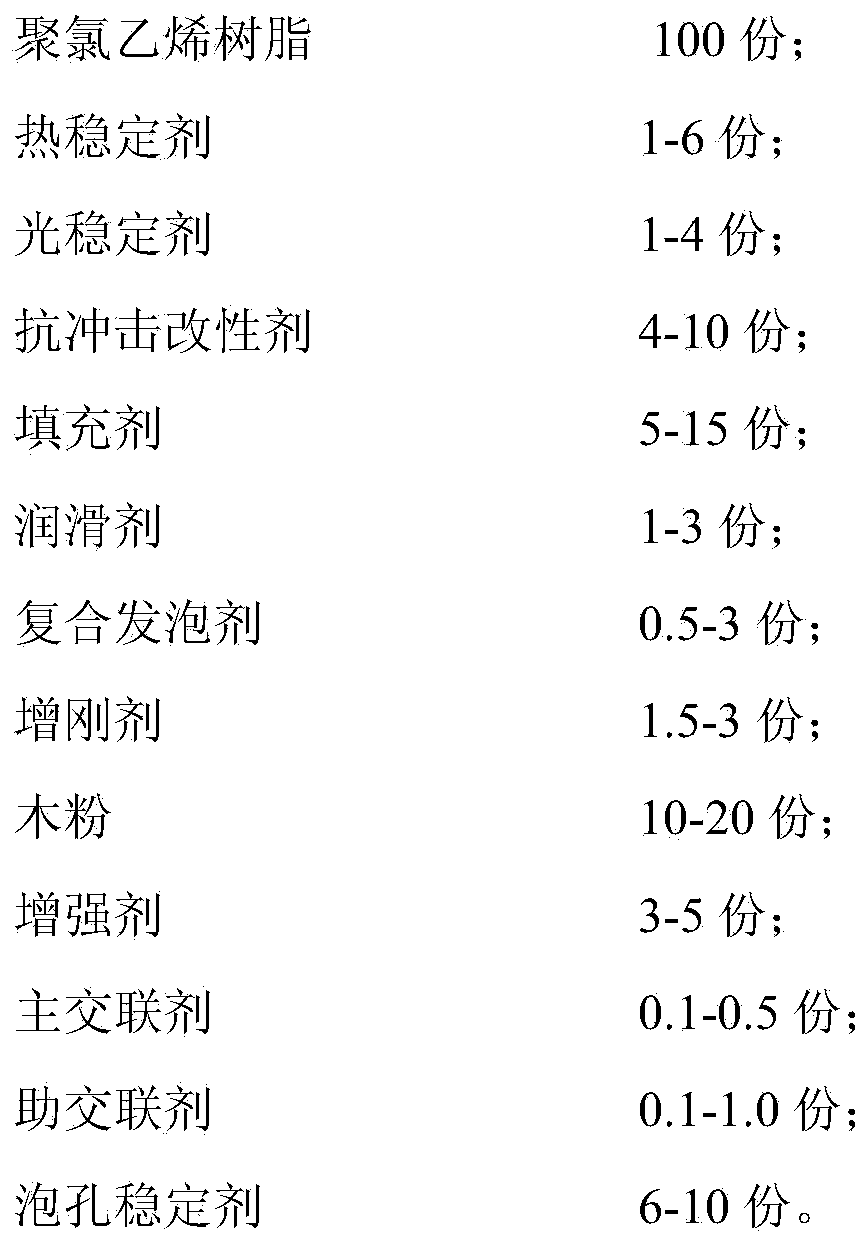

[0024] The weather-resistant and impact-resistant polyvinyl chloride wood-plastic building formwork described in this embodiment is composed of raw materials in parts by weight as follows:

[0025]

[0026] Preparation method: First, add the raw materials of the formula amount into the high-speed mixer, heat to 120°C, put them into the cold mixer to cool, and put them into the storage bin when the material is cooled to 50°C; The mixture in the silo is added to the conical twin-screw extruder to be heated and melted. The molten material enters the confluence core through the screw and is diverted to the hanger type foaming mold. Shaped, and then cut to get a 15mm thick weather-resistant and impact-resistant PVC wood-plastic building formwork. Among them, the twin-screw extruder is divided into four temperature control zones, the first temperature control zone temperature is 170°C, the second temperature control zone temperature is 172°C, the third temperature control zone te...

Embodiment 2

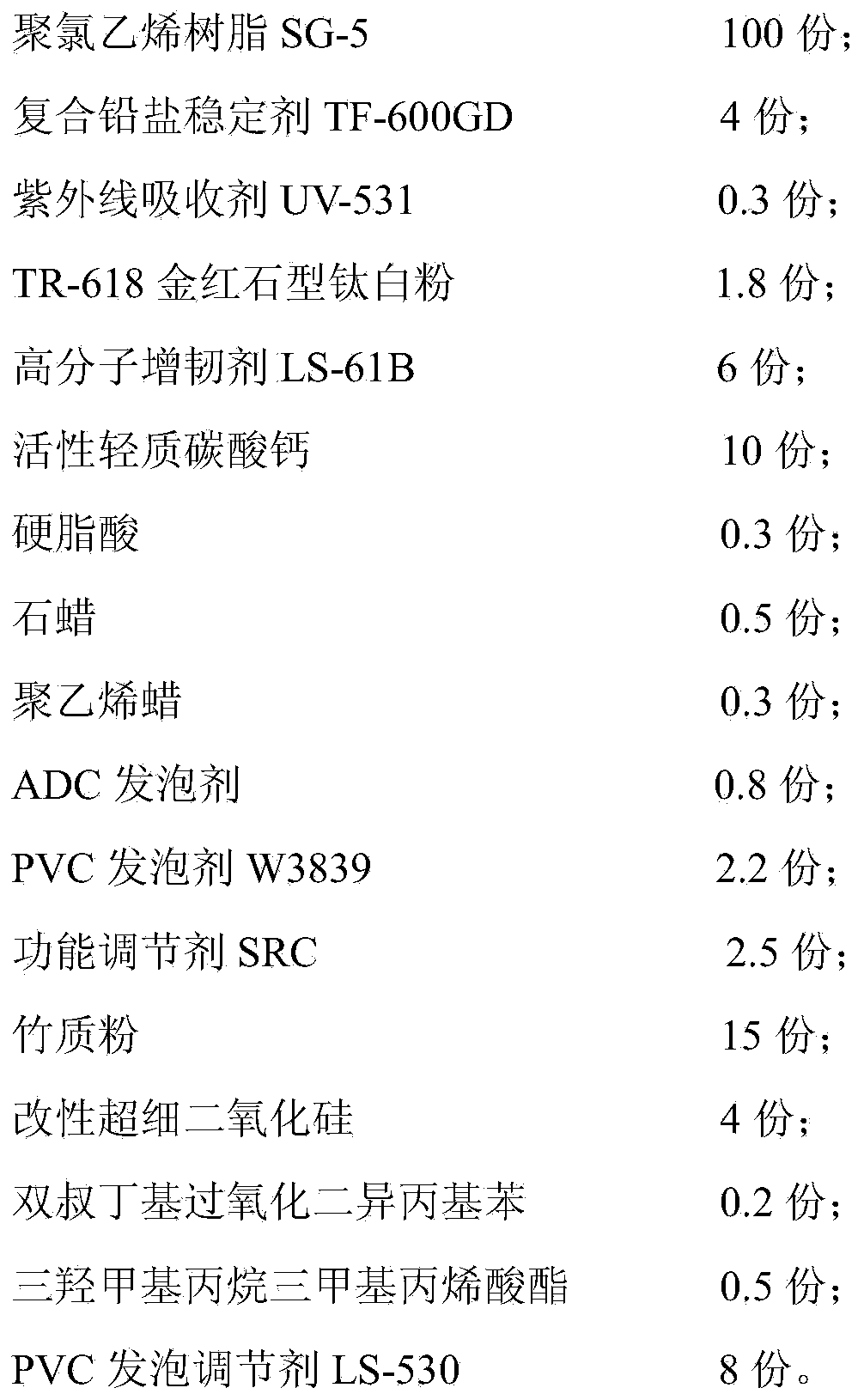

[0030] The weather-resistant and impact-resistant polyvinyl chloride wood-plastic building formwork described in this embodiment is composed of raw materials in parts by weight as follows:

[0031]

[0032] Preparation method: First, add the raw materials of the formula amount into the high-speed mixer, heat to 115°C, put it into the cold mixer to cool, and put it into the storage bin when the material is cooled to 45°C; The mixture in the silo is added to the conical twin-screw extruder to be heated and melted. The molten material enters the confluence core through the screw and is diverted to the hanger type foaming mold. Shaped, and then cut to get a 15mm thick weather-resistant and impact-resistant PVC wood-plastic building formwork. Among them, the twin-screw extruder is divided into four temperature control zones, the temperature of the first temperature control zone is 168°C, the temperature of the second temperature control zone is 171°C, the temperature of the thir...

Embodiment 3

[0036] The weather-resistant and impact-resistant polyvinyl chloride wood-plastic building formwork described in this embodiment is composed of raw materials in parts by weight as follows:

[0037]

[0038] Preparation method: First, add the raw materials of the formula amount into the high-speed mixer, heat to 120°C, put them into the cold mixer to cool, and put them into the storage bin when the material is cooled to 45°C; The mixture in the silo is added to the conical twin-screw extruder to be heated and melted. The molten material enters the confluence core through the screw and is diverted to the hanger type foaming mold. Shaped, and then cut to get a 15mm thick weather-resistant and impact-resistant PVC wood-plastic building formwork. Among them, the twin-screw extruder is divided into four temperature control zones, the temperature of the first temperature control zone is 165°C, the temperature of the second temperature control zone is 168°C, the temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Charpy impact strength | aaaaa | aaaaa |

| Vicat softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com