Electrochemical decontamination electrolyte

An electrolyte and electrochemical technology, applied in the field of electrochemical decontamination electrolyte, can solve the problems of incapable of taking into account the decontamination effect, the problem of decontamination waste liquid treatment, the unsuitability of electrolyte, etc., to achieve good decontamination effect, Taking into account the problem of decontamination waste liquid treatment and the effect of fast decontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

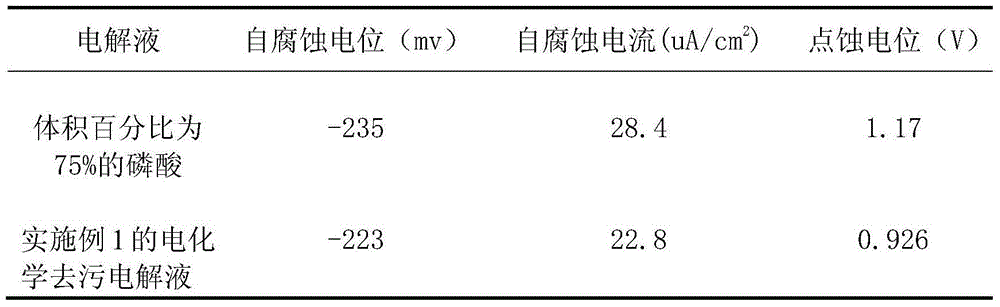

[0027] The electrochemical decontamination electrolyte of the present invention is used for electrochemical decontamination of radioactively contaminated stainless steel, and the ratio of the electrolyte used is: 0.5 mol / L nitric acid + 5 g / L oxalic acid + 1 g / L citric acid.

[0028] The specific operation is: add an appropriate amount of the above electrolyte into the electrolytic cell, immerse the stainless steel sheet to be decontaminated into the electrolyte, and use 8V direct current for constant potential electrolysis for 120s. The weight loss of the stainless steel sheet is 6.4mg / cm. 2 . Use deionized water to rinse the decontaminated stainless steel sheet, and the measured surface radioactivity level of the stainless steel sheet meets the reuse requirements.

Embodiment 2

[0030] The electrochemical decontamination electrolyte of the present invention is used for electrochemical decontamination of radioactively contaminated stainless steel, and the used electrolyte ratio is: 0.5 mol / L nitric acid + 5 g / L oxalic acid + 10 g / L citric acid.

[0031] The operation method is the same as in Example 1. The weight loss of the stainless steel sheet is 8.0mg / cm. 2 , The measured radioactivity level on the surface of the stainless steel sheet meets the reuse requirements.

Embodiment 3

[0033] The electrochemical decontamination electrolyte of the present invention is used for electrochemical decontamination of radioactively contaminated stainless steel, and the ratio of the electrolyte used is: 0.25 mol / L nitric acid + 9 g / L oxalic acid + 5 g / L citric acid.

[0034] The operation method is the same as in Example 1, and the weight loss of the stainless steel sheet is measured to be 5.7mg / cm 2 , The measured radioactivity level on the surface of the stainless steel sheet meets the reuse requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com