Concrete faced rockfill dam on deep covering layer and construction method

A face rockfill dam and deep overburden technology, applied in the direction of dams, barrages, barrages, etc., can solve the problems of difficulty in ensuring the overall stability of the dam body, construction quality and stability of the dam body, etc., and achieve deformation Uniformity, strength reduction, pore water pressure reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

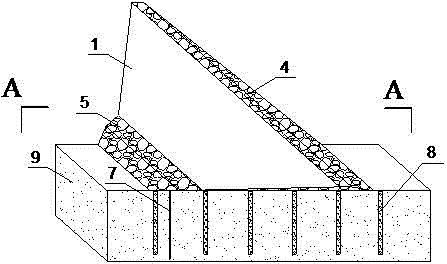

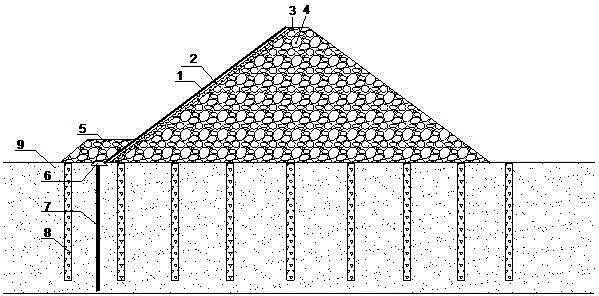

[0030] Such as Figure 1~2 As shown, a face rockfill dam with a deep cover layer includes a dam body 4 and a cover layer 9, the dam body 4 is arranged on the cover layer 9, and a transition layer 3 is set on the upstream side of the dam body 4, and the transition layer 3 An anti-filter layer 2 is arranged on the upper cover, and a panel 1 is covered on the anti-filter layer 2, and the bottom end of the panel 1 is arranged on the cover layer 9 through the connecting plate 6; the anti-seepage wall 7 and gravel are vertically arranged inside the cover layer 9 The pile 8 and the top of the cut-off wall 7 are connected to the connecting plate 6, and the upstream ballast 5 is arranged above the connecting plate 6.

[0031] Among them, the thickness of the covering layer 9 is greater than 100m; the height of the dam body 4 filled with rockfill is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com