Composite PE (Poly Ethylene) gas pipe

A gas pipe, gas technology, applied in the direction of pipes, pipe components, rigid pipes, etc., can solve the problems of low compressive strength, no installation, low safety performance, etc., to prevent aging and bending deformation, improve service life, pipe The effect of simple body structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

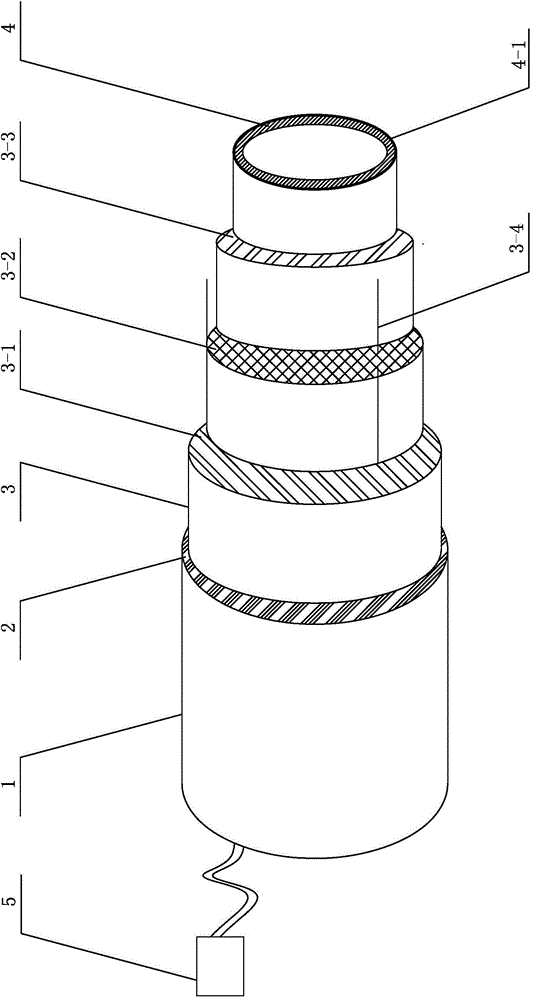

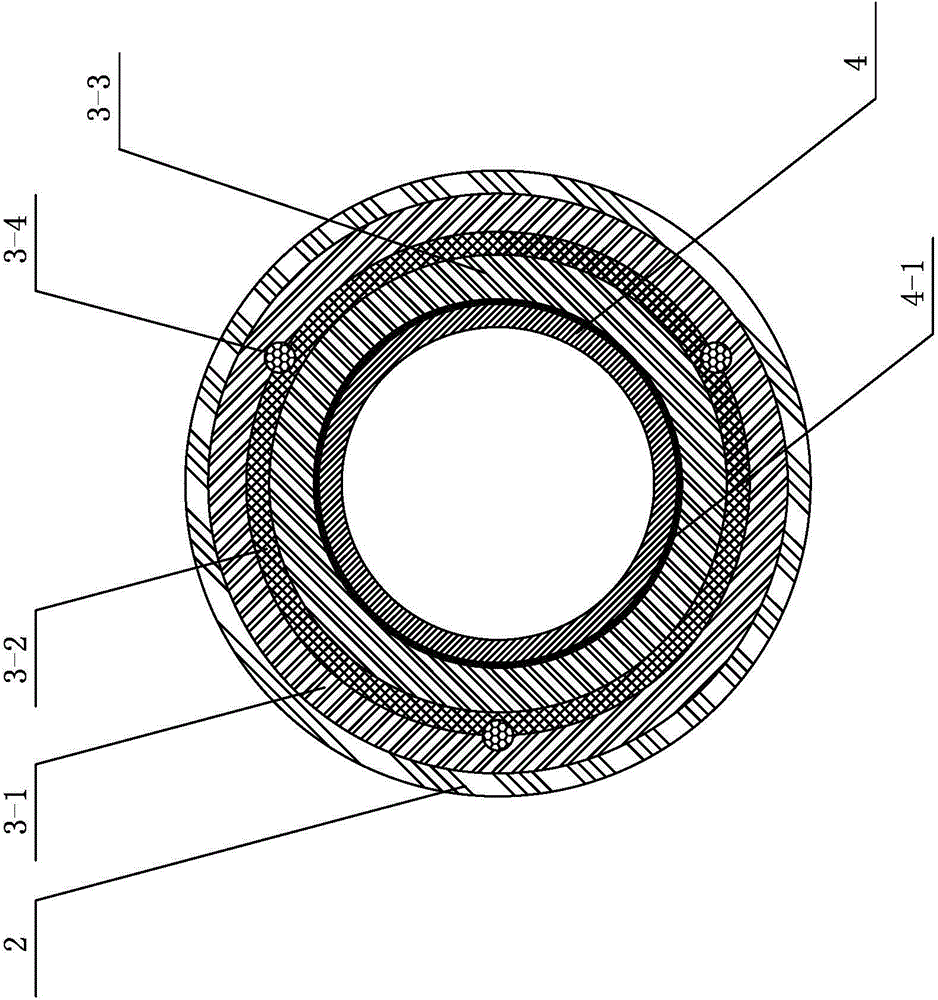

[0019] Such as figure 1 and figure 2 As shown, a specific embodiment of the present invention is proposed, a PE composite gas pipe, including a pipe body 1, and the pipe body 1 is an anti-corrosion layer 2, a base layer 3, and a rubber layer 4 for gas from the outside to the inside; The etching layer 2 is made of matrix resin and modified auxiliary materials.

[0020] Such as figure 1 As shown, the base layer 3 includes a PE outer layer 3-1, a metal mesh core layer 3-2, a PE inner layer 3-3, and a plurality of roots are arranged between the PE outer layer 3-1 and the metal mesh core layer 3-2. The metal wire 3-4 extending axially along the tube body 1 to both ends of the tube body 1, the metal wire 3-4 is evenly distributed on the outer peripheral surface of the metal mesh core layer 3-2, one end of the metal wire 3-4 is connected to the tube The detector alarm 5 at the end of the body 1 is connected; the preferred setting of the present embodiment is that the PE outer lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com