Gas sensor chip

A gas sensor and chip technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as insufficient contact between chip electrodes and measuring gas, chip strength not meeting strength requirements, and affecting sensing effects, etc., to achieve compensation performance Can not take into account, simple structure, good selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

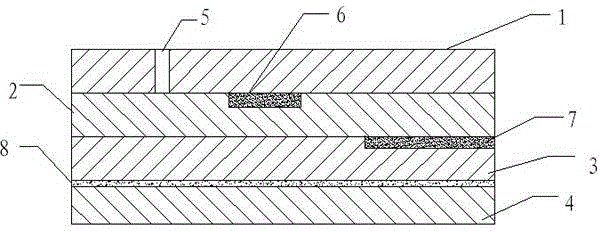

[0032] A gas sensor chip, which is formed by laminating four layers of piezoelectric substrates from the first layer to the fourth layer, wherein,

[0033] The first piezoelectric substrate 1 is provided with a reference gas channel 5;

[0034] A reference electrode 6 is arranged between the first piezoelectric substrate 1 and the second piezoelectric substrate 2, and the reference gas channel 5 communicates with the reference electrode 6;

[0035]A heating electrode 7 is arranged between the second layer of piezoelectric substrate 2 and the third layer of piezoelectric substrate 3, and the second layer of piezoelectric substrate 2 is coated with a gas sensitive film, and the sensitive film is Polymer membranes with adsorption and desorption properties for the corresponding gases;

[0036] A disordered metal film 8 is arranged on the fourth piezoelectric substrate 4 , and point electrodes are arranged on the disordered metal film 8 .

[0037] The manufacturing method of this...

Embodiment 2

[0044] A gas sensor chip, which is formed by laminating four layers of piezoelectric substrates from the first layer to the fourth layer, wherein,

[0045] The first piezoelectric substrate 1 is provided with a reference gas channel 5; the piezoelectric substrate is made of zirconia;

[0046] A reference electrode 6 is arranged between the first piezoelectric substrate 1 and the second piezoelectric substrate 2, the reference gas channel 5 communicates with the reference electrode 6, and the reference electrode 6 is covered with a porous alumina layer, and the reference gas channel 5 communicates with the porous alumina layer;

[0047] A heating electrode 7 is arranged between the second layer of piezoelectric substrate 2 and the third layer of piezoelectric substrate 3, and the second layer of piezoelectric substrate 2 is coated with a gas sensitive film, and the sensitive film is Polymer membranes with adsorption and desorption properties for the corresponding gases;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com